Preparation method of mesoporous cellulose fiber material

A cellulose fiber and cellulose technology, applied in the field of preparation of mesoporous cellulose fiber materials, can solve problems such as environmental pollution, difficulty in obtaining nanofibers, and high cost of organic solvents, and achieve resource shortage, wide application prospects, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

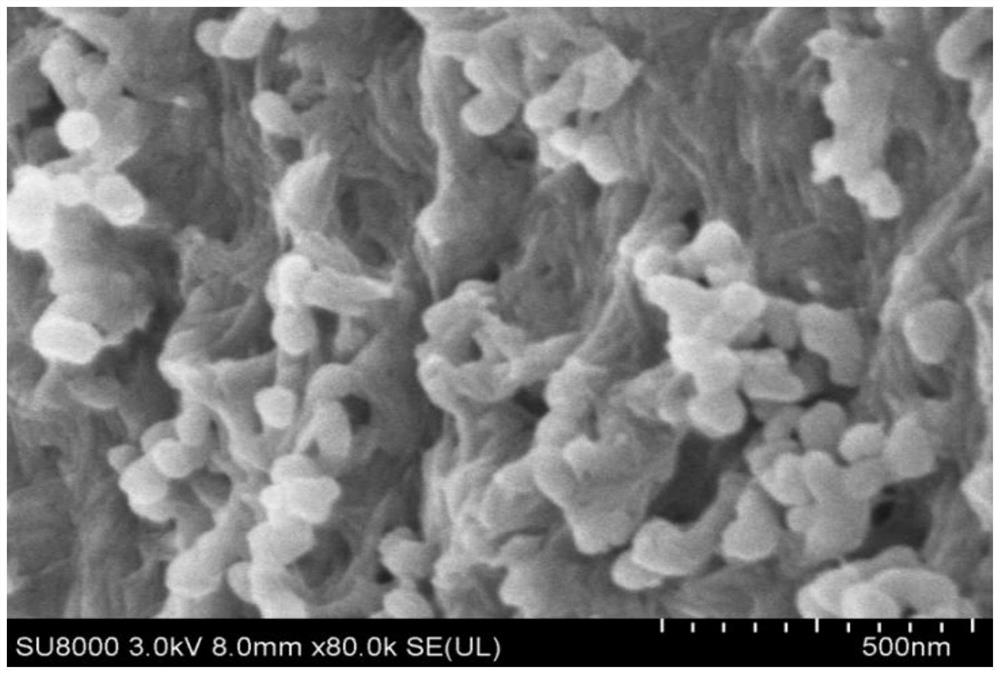

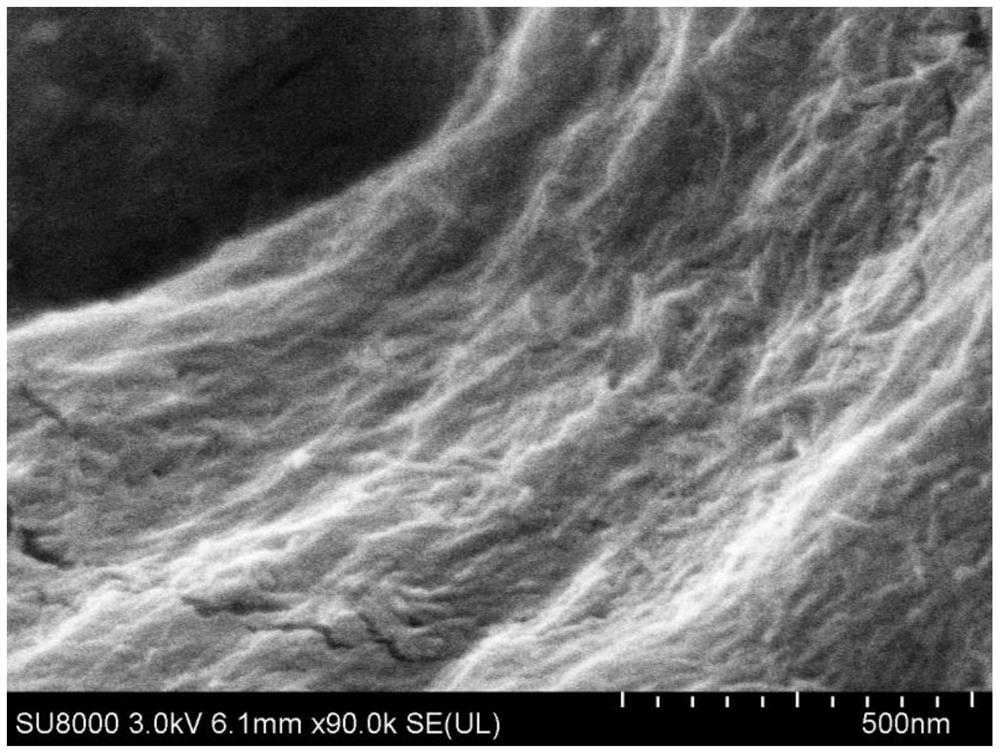

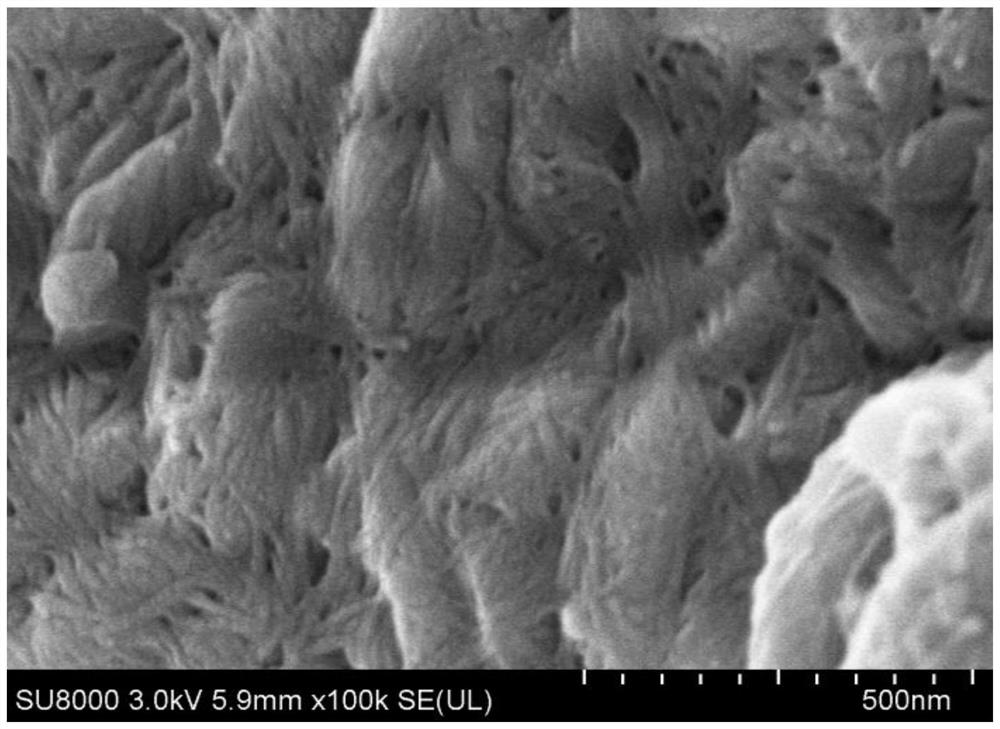

[0030] A kind of preparation method of mesoporous cellulose fiber material of the present invention, specifically implement according to the following steps:

[0031] Configure concentrated sulfuric acid with a mass fraction of 64%, stir under a constant temperature water bath at 45-60°C, add microcrystalline cellulose after the solution temperature is stable, wherein each gram of microcrystalline cellulose corresponds to 8.75ml of sulfuric acid, and react at a stirring speed of 300-600rpm 30-45min, after the reaction is completed, pour it into 10 times the volume of deionized water to obtain the mixed solution A; let the mixed solution A stand for 12-24h, pour off the supernatant to obtain the lower milky white turbid solution, and the lower milky white The turbid liquid is centrifuged at 9000-12000rmp for 20-30min in a centrifuge to obtain a milky white suspension; put the milky white suspension into a dialysis bag for dialysis, the dialysis time is 3-6 days, replace the deio...

Embodiment 1

[0033] A kind of preparation method of mesoporous cellulose fiber material of the present invention, specifically implement according to the following steps:

[0034] Configure concentrated sulfuric acid with a mass fraction of 64%, stir under a constant temperature water bath at 45°C, add microcrystalline cellulose after the solution temperature is stable, wherein each gram of microcrystalline cellulose corresponds to 8.75ml of sulfuric acid, react at a stirring speed of 300rpm for 30min, and wait for the reaction After completion, pour it into 10 times the volume of deionized water to obtain the mixed solution A; let the mixed solution A stand for 12 hours, pour off the supernatant to obtain the lower milky white turbid solution, and centrifuge the lower milky white turbid solution through a centrifuge at 9000rmp 20min, obtain the milky white suspension; Put the milky white suspension into the dialysis bag (8KD) and carry out dialysis, the dialysis time is 3 days, every 6h re...

Embodiment 2

[0036] A kind of preparation method of mesoporous cellulose fiber material of the present invention, specifically implement according to the following steps:

[0037]Configure concentrated sulfuric acid with a mass fraction of 64%, stir under a constant temperature water bath at 45°C, add microcrystalline cellulose after the solution temperature is stable, wherein each gram of microcrystalline cellulose corresponds to 8.75ml of sulfuric acid, react at a stirring speed of 350rpm for 35min, and wait for the reaction After completion, pour it into 10 times the volume of deionized water to obtain the mixed solution A; let the mixed solution A stand for 15 hours, pour off the supernatant to obtain the lower layer of milky white turbid liquid, and centrifuge the lower layer of milky white turbid liquid through a centrifuge at 9000rmp After 23min, the milky white suspension was obtained; the milky white suspension was put into a dialysis bag (9KD) for dialysis, and the dialysis time w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com