Composite fiber membrane for preventive protection of paper cultural relics and preparation method of composite fiber membrane

A technology for composite fiber and paper cultural relics, which is applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of reversible and difficult applications, and achieve the effect of reliable quality, high repeatability, and increased contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

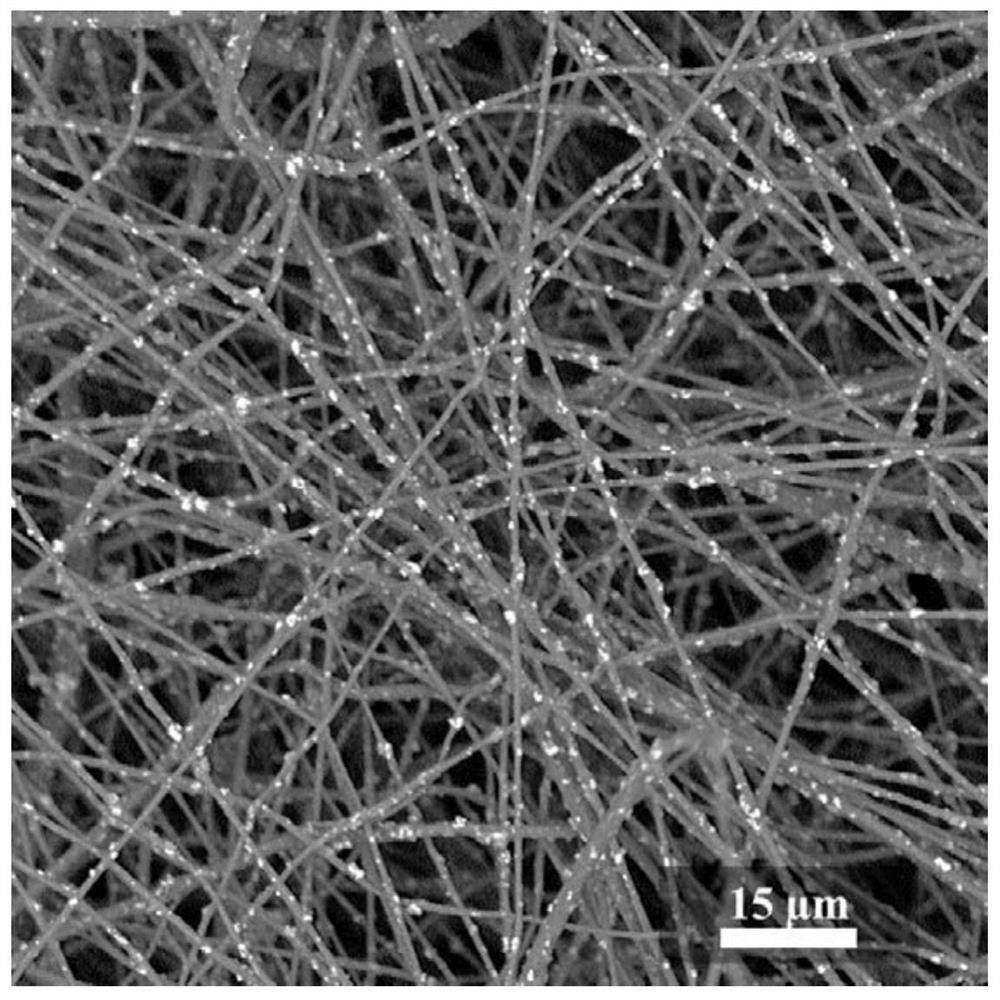

[0033] Dissolve titanium dioxide and polyvinylidene fluoride in a mixed solvent of N,N-dimethylformamide and acetone (mass ratio 4:1) to form a polymer solution with a mass fraction of 12 wt%, wherein the ultraviolet shielding agent and polymer The mass ratio is 0.8:1.

[0034] The spinneret is connected to +15kV voltage, and the receiving device is connected to -0.5kV voltage. The distance between the spinneret and the receiving device was 15 cm, and the supply rate of the spinning solution was 3 mL / h. The temperature of the spinning environment is 25° C. and the relative humidity is 60%. After spinning, the solvent is completely evaporated to obtain composite fibers.

[0035] Dissolve ciprofloxacin and hydrogenated poly(styrene-butadiene-styrene) in a mixed solvent of N,N-dimethylformamide and acetone (mass ratio 4:1) to form a mass fraction of 8wt% The polymer solution, wherein the mass ratio of drug to polymer is 0.5:1.

[0036] The composite fiber in the previous step...

Embodiment 2

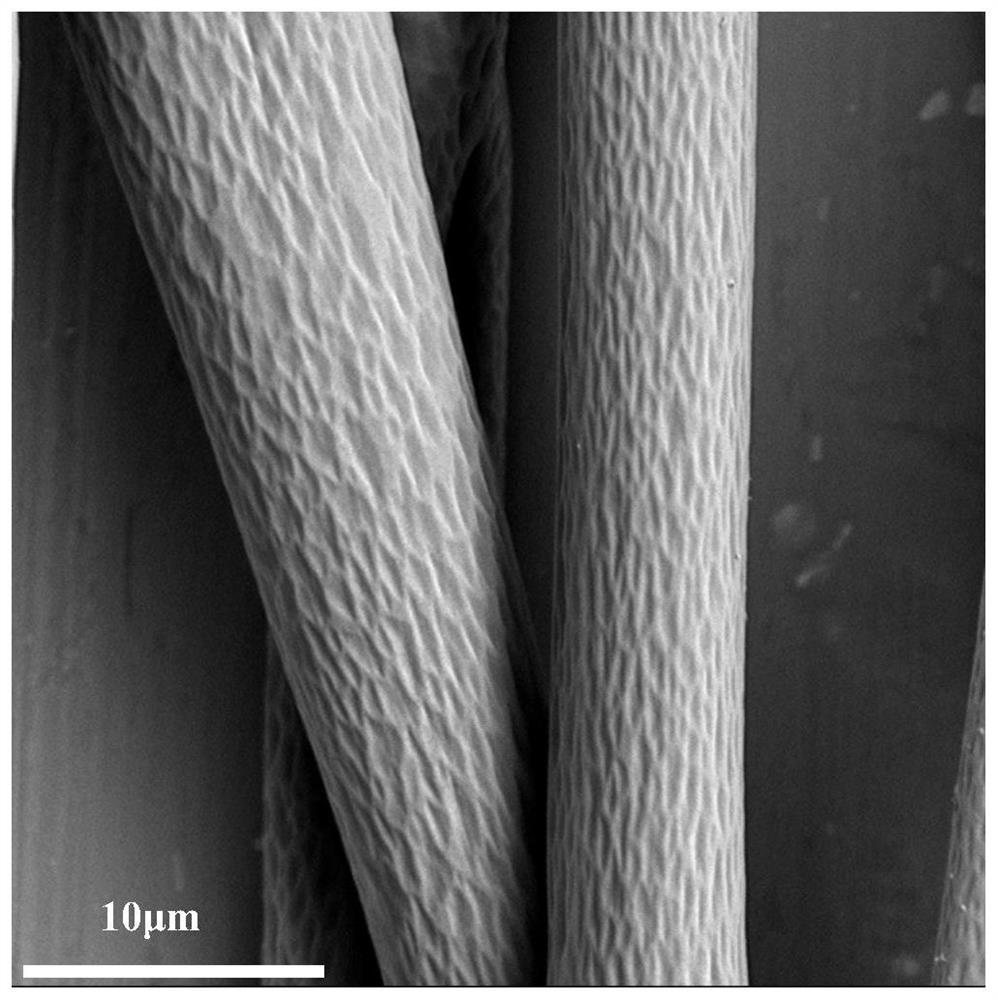

[0038] Dissolve ciprofloxacin and polyvinylidene fluoride in a mixed solvent of N,N-dimethylformamide and acetone (mass ratio 4:1) to form a polymer solution with a mass fraction of 12wt%, in which the drug and high The mass ratio of the molecules is 0.5:1.

[0039] The spinneret is connected to +15kV voltage, and the receiving device is connected to -0.5kV voltage. The distance between the spinneret and the receiving device was 15 cm, and the supply rate of the spinning solution was 3 mL / h. The temperature of the spinning environment is 25° C. and the relative humidity is 60%. After spinning, the solvent is completely evaporated to obtain composite fibers.

[0040] Dissolve zinc oxide and hydrogenated poly(styrene-butadiene-styrene) in a mixed solvent of N,N-dimethylformamide and acetone (mass ratio 4:1) to form a high Molecular solution, in which the mass ratio of drug to polymer is 0.5:1.

[0041]The composite fiber in the previous step is used as a receiving device, th...

Embodiment 3

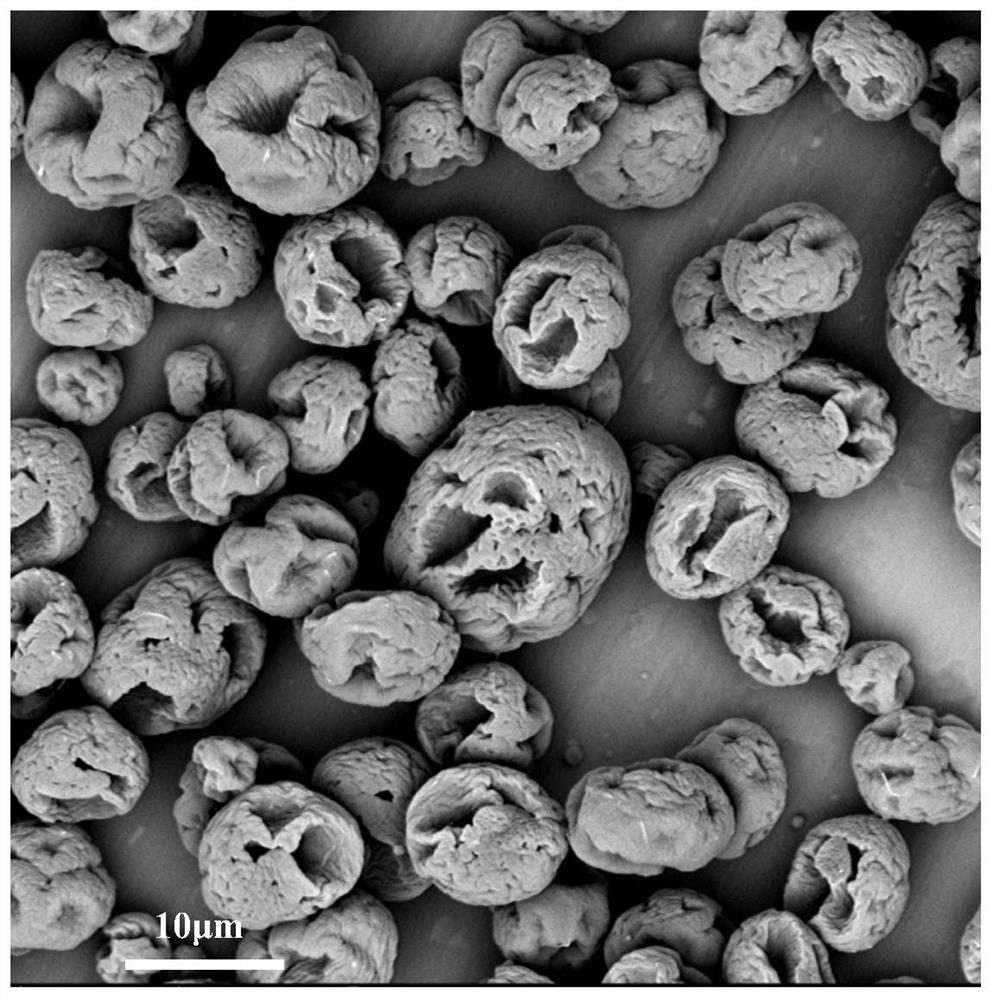

[0043] Dissolve curcumin and hydrogenated poly(styrene-butadiene-styrene) in a mixed solvent of N,N-dimethylformamide and acetone (mass ratio 4:1) to form a high Molecular solution, in which the mass ratio of drug to polymer is 0.2:1.

[0044] The spinneret is connected to +14kV voltage, and the receiving device is connected to -1kV voltage. The distance between the spinneret and the receiving device was 15 cm, and the supply rate of the spinning solution was 1 mL / h. The temperature of the spinning environment is 25° C. and the relative humidity is 40%. After spinning, the solvent is completely evaporated to obtain composite fibers.

[0045] Carbon black and polyacrylonitrile were dissolved in N,N-dimethylformamide to form a polymer solution with a mass fraction of 4 wt%, in which the mass ratio of drug to polymer was 0.2:1.

[0046] The composite fiber in the previous step is used as a receiving device, the spinneret is connected to a voltage of +10kV, and the receiving de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com