Metal organic framework/epoxy coating, and preparation method and application thereof

A metal-organic framework and epoxy coating technology, applied in the field of coatings, can solve the problems of high doping coating preparation cost, increasing doping content, etc., and achieve strong corrosion protection performance and integrity, and low doping content , The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, the preparation method of zeolite methyl imidazolium ester framework nanosheet

[0042] A preparation method of zeolite methylimidazolate framework nanosheets, comprising the following steps:

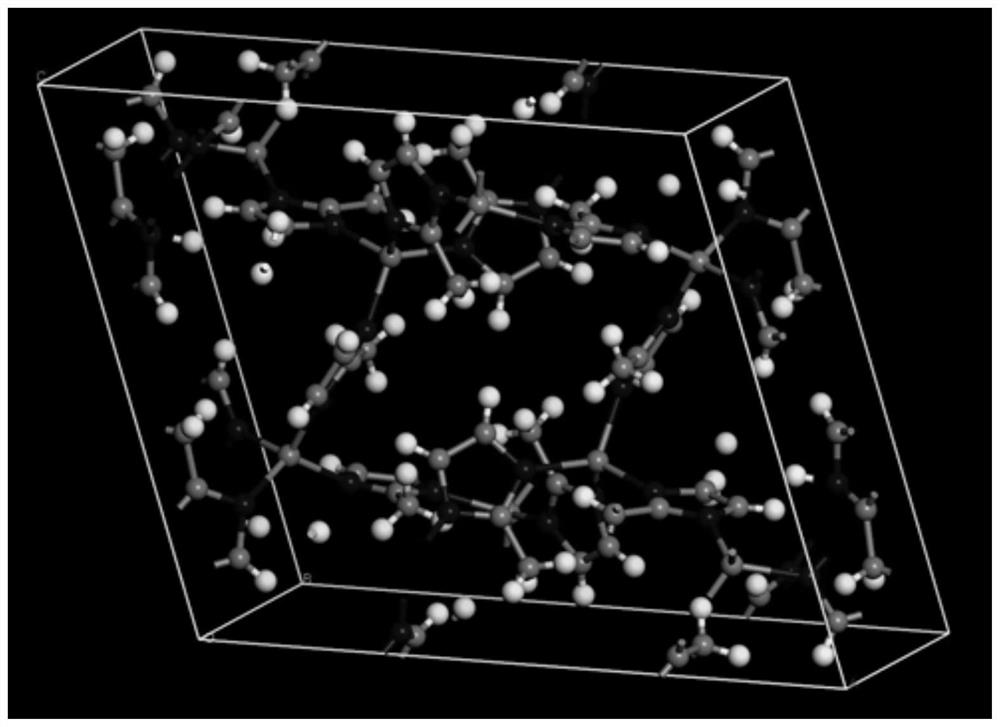

[0043] 0.33g Zn(NO 3 ) 2 ·6H 2 O was added to 90 mL of deionized water, and stirred until it was completely dissolved; similarly, 0.985 g of 2-methylimidazole was added to 90 mL of deionized water, and stirred until it was completely dissolved. Then, the above two solutions were mixed together and stirred at room temperature for 24 h to obtain a white cloudy solution. Then the above white turbid solution was centrifuged at 8000rpm for 5min, and washed 3 times with deionized water. Finally, the collected white solid was vacuum-dried at 110°C for 4 hours to obtain a white powder that is zeolite methylimidazolate framework nanosheets (average size 2-5 μm, refer to the crystal structure diagram figure 1 ).

[0044] The reaction formula for preparing zeolite methyl...

Embodiment 2

[0046] Embodiment 2, the preparation method of zeolite methylimidazolate skeleton nanoparticle

[0047] A preparation method of zeolite methylimidazolate framework nanoparticles, comprising the following steps:

[0048] Add 1.6 g of 2-methylimidazole into 20 mL of deionized water and stir until completely dissolved; similarly, dissolve 1.225 g of zinc nitrate hexahydrate in 30 mL of deionized water. After the two substances are completely dissolved, use a dropper to slowly add the solution containing zinc nitrate hexahydrate into the 2-methylimidazole solution. The dropwise addition process is about 10 minutes. After completion, cover with plastic wrap and continue to react at room temperature under stirring conditions. 2 hours. Then the product was centrifuged at 8000r / min for 5 minutes, and washed 3 times with deionized water. Finally, dry in an oven at 110° C. for 8 hours (or in a vacuum oven at 110° C. for 4 hours) to obtain a white powder that is zeolite methylimidazola...

Embodiment 3

[0049] Embodiment 3, a kind of zeolite methylimidazolium ester framework nanosheet / epoxy composite coating and preparation method thereof

[0050] A preparation method of zeolite methyl imidazolate skeleton nanosheet / epoxy composite coating, comprising the following steps:

[0051] S1. Take 0.01 g of the zeolite methylimidazolate skeleton nanosheets prepared in Example 1 and add them to 5 mL of methanol, and after ultrasonic treatment for 30 min, stir until completely dissolved to obtain a mixed solution;

[0052] S2. Add 10g of E-44 epoxy resin to the mixed solution, stir evenly, and ultrasonically again for 2 hours to obtain a white turbid solution;

[0053] S3, add 2.5g aliphatic amine to the white turbid liquid and stir evenly, vacuum degassing for 5min, obtain zeolite methylimidazolate skeleton nanosheet / epoxy coating;

[0054] S4. Scrape-coat the above-mentioned zeolite methylimidazolium ester skeleton nanosheets / epoxy coating on the surface of the aluminum plate with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap