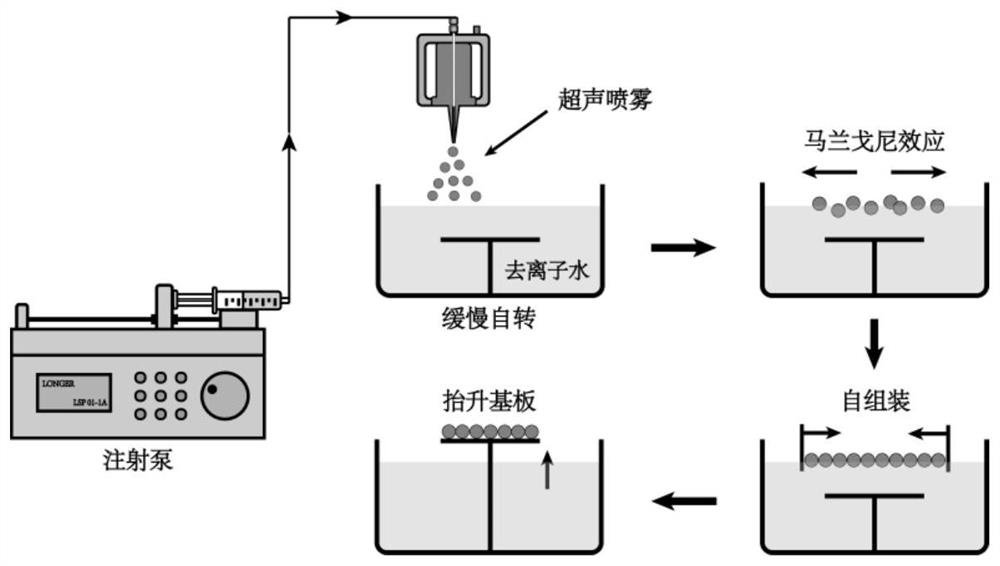

A method for preparing large-area single-layer colloidal crystal templates by ultrasonic spraying

A single-layer colloidal crystal, ultrasonic spray technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of PS microspheres sinking into water, destroying the dynamic balance of liquid level, etc., to avoid unstable factors , the effect of enhancing robustness and reducing likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

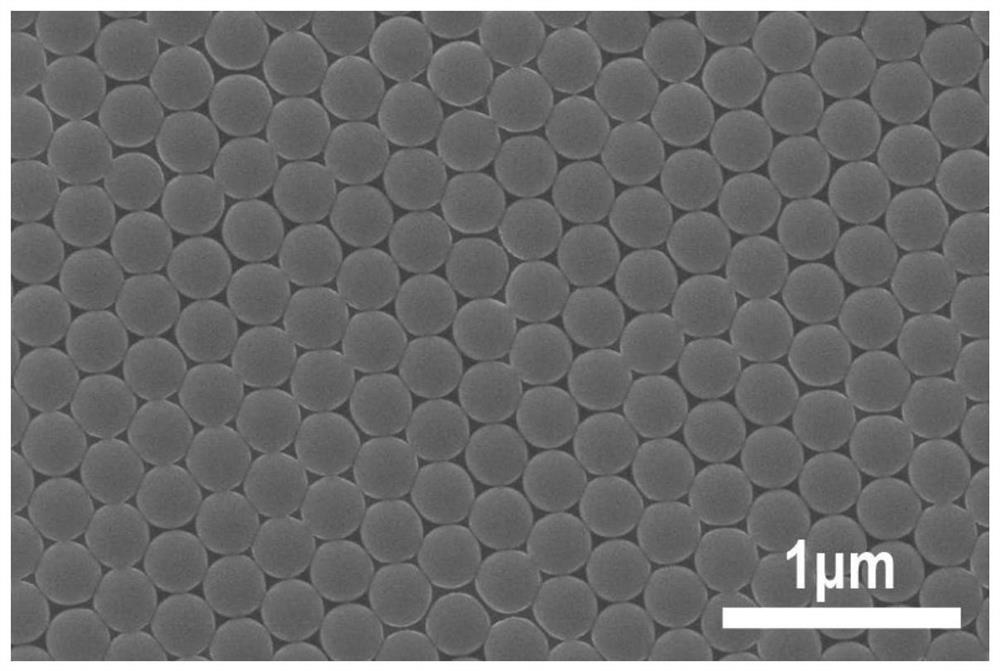

Embodiment 1

[0037] Step 1: Dilute the PS nano-microsphere stock solution (particle size 250 nm, concentration 2.5 wt%) with absolute ethanol in a volume ratio of 1:1, and then ultrasonically disperse for 5 min. Use a 10mL syringe to draw 2mL of the prepared nanosphere dispersion.

[0038] Step 2: Cut the silicon wafer into 1×1cm 2 The size of the substrate was pre-sonicated in absolute ethanol, acetone, chloroform, and deionized water for 15 min, respectively, and then boiled in piranha solution and ammonia solution for 30 min for super-hydrophilic treatment.

[0039] Step 3: Connect the syringe to the infusion line, and connect the other end of the infusion line to the ultrasonic spray head. At the same time, a disposable lunch box is used to hold about 2 / 3 of deionized water, and the processed silicon wafer substrate is pre-placed under the water surface at a distance of 5 mm from the water surface and inclined at 15°.

[0040] Step 4: Set the liquid volume of the syringe pump to 0.3m...

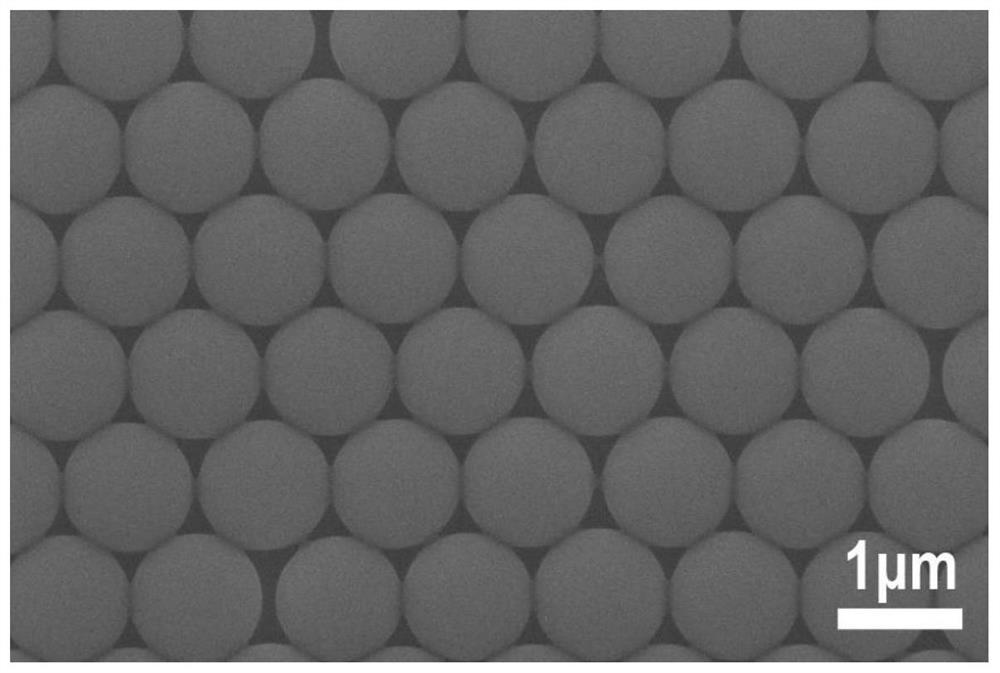

Embodiment 2

[0045]Step 1: Dilute the PS nano-microsphere stock solution (particle size 1054 nm, concentration 2.5 wt%) with absolute ethanol in a volume ratio of 1:1.2, followed by ultrasonic vibration for 5 min. Use a 10mL syringe to draw 5mL of the prepared nanosphere dispersion.

[0046] Step 2: Cut the glass into 1×1cm 2 The size of the substrate was pre-sonicated in absolute ethanol, acetone, chloroform, and deionized water for 15 min, and then boiled in piranha solution for 30 min for hydrophilic treatment.

[0047] Step 3: Connect the syringe to the infusion line, and connect the other end of the infusion line to the ultrasonic spray head. At the same time, use a disposable lunch box to hold about 2 / 3 of deionized water, and pre-place the treated glass sheet substrate 5mm below the water surface to keep it level.

[0048] Step 4: Set the volume of the syringe pump to 1.5mL and the injection speed to 5mL / h. Turn on the syringe pump, and turn on the control power of the nozzle sim...

Embodiment 3

[0053] Step 1: First, mix PS nano-microsphere stock solution 1 (particle size 310nm, concentration 2.5wt%) and PS nano-microsphere stock solution 2 (particle size 1054nm, concentration 2.5wt%) according to the volume ratio V S / L = 0.051 for mixing, then dilute with absolute ethanol at a volume ratio of 1:1.2, and ultrasonically disperse for 5 min. Use a 10mL syringe to draw 5mL of the prepared nanosphere dispersion.

[0054] Step 2: Cut the glass into 1×1cm 2 The size of the substrate was pre-sonicated in absolute ethanol, acetone, chloroform, and deionized water for 15 min, and then boiled in piranha solution for 30 min for hydrophilic treatment.

[0055] Step 3: Connect the syringe to the infusion line, and connect the other end of the infusion line to the ultrasonic spray head. At the same time, use a disposable lunch box to hold about 2 / 3 of deionized water, and pre-place the treated glass sheet substrate 5mm below the water surface to keep it level.

[0056] Step 4: Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com