Iron removal method for preparing high-purity boric acid

A technology of high-purity boric acid and boric acid, which is applied in the direction of boron oxyacids and boron oxide compounds, can solve the problem that the production technology of high-purity boron products has not been broken through, and the content of iron borate ions cannot reach high-purity boric acid. Removal methods and other issues to achieve the effect of saving iron removal costs, reducing iron removal costs, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

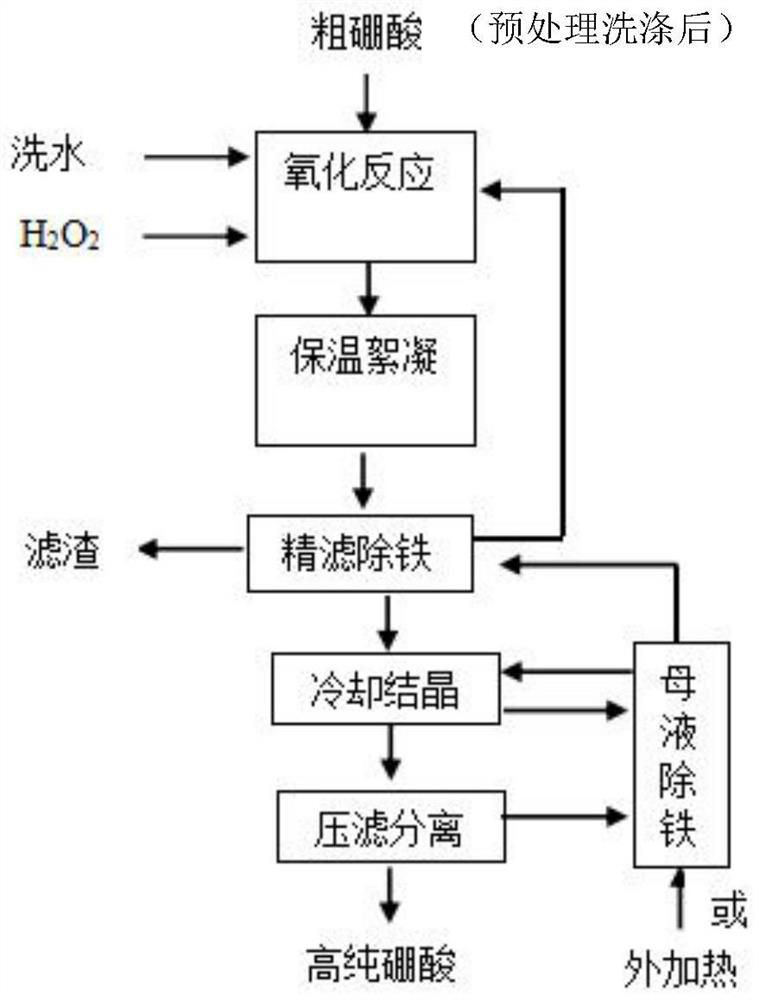

[0139] The salt lake crude boric acid is used as the raw material, and the iron is removed after pretreatment and washing.

[0140] Put salt lake crude boric acid in a container, add tap water and stir for 30 minutes at room temperature, use a centrifuge to separate solid and liquid, and obtain wet material crude boric acid, wherein the dosage ratio of salt lake crude boric acid and tap water is 1kg:1L.

[0141] The appearance of crude boric acid in salt lake is gray-white viscous fine particles and needle-like crystals, and the composition content is as follows in terms of mass fraction: H 3 BO 3 94.08%, MgO 0.18%, CaO 0.082%, Cl 0.73%, SO 4 2- 0.061%, Fe0.0220%;

[0142] The crude boric acid appearance after washing pretreatment is white fine particle and needle-like crystal, by mass fraction, composition content is as follows: H 3 BO 3 89.47%, MgO 0.0027%, CaO 0.012%, Cl 0.055%, SO 4 2- 0.032%, Fe 0.0120%.

[0143] The specific steps of iron removal are as follows: ...

Embodiment 2

[0151] The salt lake crude boric acid is used as the raw material, and the iron is removed after pretreatment and washing.

[0152] Put salt lake crude boric acid in a container, add tap water and stir for 30 minutes at room temperature, use a centrifuge to separate solid and liquid to obtain wet material crude boric acid, wherein the dosage ratio of salt lake crude boric acid to tap water is 1kg:1L.

[0153]The appearance of crude boric acid in salt lake is gray white viscous slippery fine particles and needle-like crystals, and the composition content is analyzed as follows in terms of mass fraction: H 3 BO 3 89.78%, MgO 0.26%, CaO 0.19%, Cl 0.56%, SO 4 2- 0.022%, Fe0.021%;

[0154] The appearance of crude boric acid after washing and pretreatment is white fine particles and needle-like crystals, and the component analysis content is as follows: H 3 BO 3 90.78%, MgO 0.0031%, CaO 0.022%, Cl 0.010%, SO 4 2- 0.0087%, Fe 0.0098%.

[0155] (1) Get 6kg of the crude boric a...

Embodiment 3

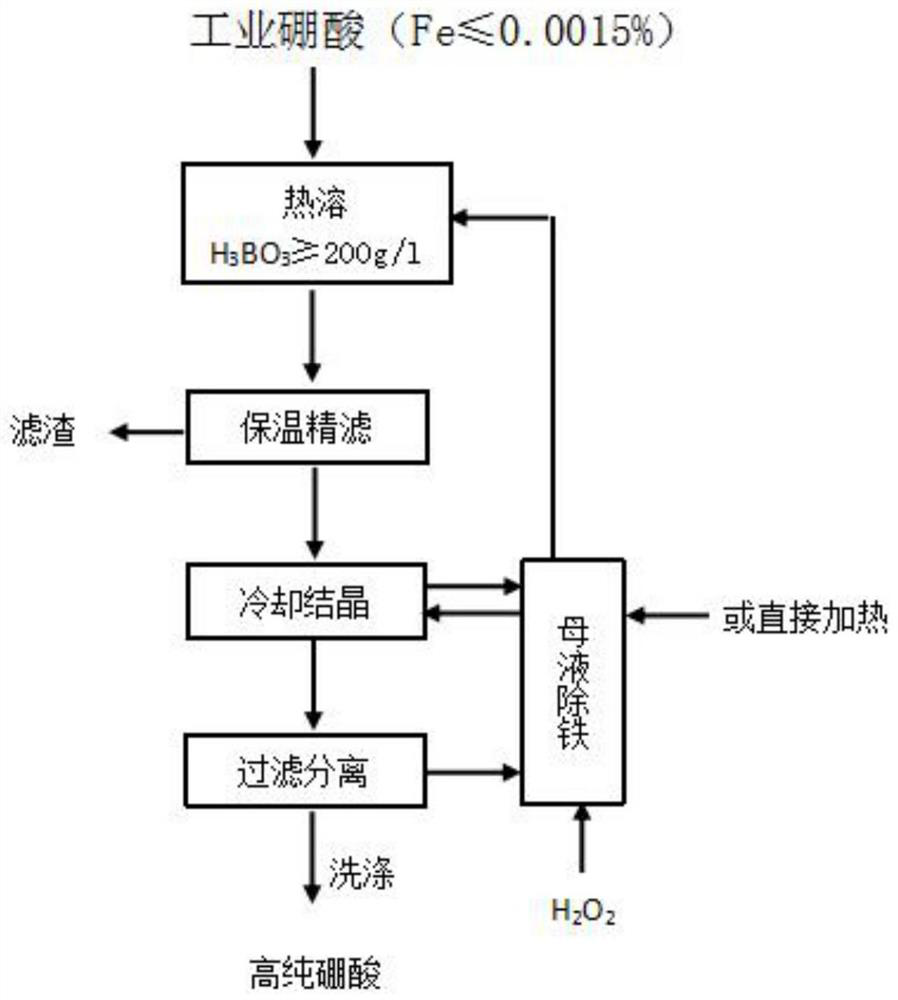

[0162] Adopt the purchased industrial boric acid as raw material to carry out iron removal, the industrial boric acid appearance is white fine particles, in terms of mass fraction, the composition content analysis is as follows: H 3 BO 3 99.54%, MgO—, CaO—, Cl0.01%, SO 4 2- 0.30%, Fe 0.0015%;

[0163] (1) Get the above-mentioned industrial boric acid of 8kg, drop into the container of 56L deironing mother liquor, start stirring and heating; Described container is the cylinder of 100L stainless steel material, and supporting stainless steel stirring and speed reducer are set; The component content of deironing mother liquor is :H 3 BO 3 48.57g / L, MgO 0.011g / L, CaO 0.10g / L, Cl0.36g / L, SO 4 2- 0.11g / L, Fe0.0008g / L.

[0164] (2) Heating the feed liquid in step (1) to 40°C, adding 5g of hydrogen peroxide according to 0.05% of the boric acid mass, heating until the raw material is completely dissolved, at this moment, the temperature of the feed liquid is 73°C, the pH value i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com