Corrosion-resistant, high-temperature-resistant and super-hydrophobic polyphenylene sulfide composite material and preparation method thereof

A polyphenylene sulfide and composite material technology, which is applied in the field of polyphenylene sulfide composite material and its preparation, can solve the problems of complex use environment and need to improve mechanical properties, and achieves simple preparation method, high heat resistance and mechanical properties. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

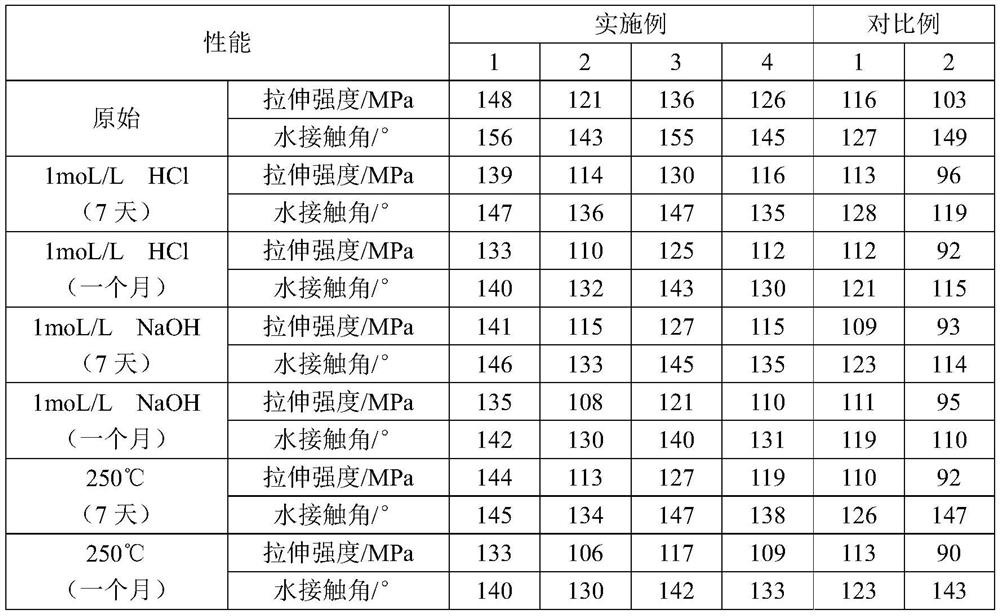

Examples

Embodiment 1

[0028] Corrosion-resistant, high-temperature-resistant, superhydrophobic polyphenylene sulfide composite material, its raw material ratio is as follows: polyphenylene sulfide resin 3kg, modified TiO 2 3kg, polytetrafluoroethylene 2kg, silane coupling agent 1kg, EPDM rubber grafted maleic anhydride 0.5kg, stearic acid 0.5kg. The average molecular weight of the polyphenylene sulfide resin in this embodiment is 10000, but it is not limited thereto.

[0029] Its preparation method is as follows:

[0030] (1) Preparation of modified filler: 50 grams of hydroxy silicone oil, 10 grams of tetraethyl orthosilicate, 1 gram of dibutyltin dilauric acid, and 1000 grams of hexane were added to the flask and stirred at a speed of 300 r / min for 20 minutes to make it Mix well, then add 2000 grams of TiO 2 Continue to stir for 20 minutes, finally filter, wash and dry to obtain modified TiO 2 filler.

[0031] (2) Weigh the raw materials according to the ratio in the above formula, stir in a...

Embodiment 2

[0035] Corrosion-resistant, high-temperature-resistant, superhydrophobic polyphenylene sulfide composite material, its raw material ratio is as follows: polyphenylene sulfide resin 4kg, modified SiO 2 2kg, polytetrafluoroethylene 2kg, silane coupling agent 1kg, hydrogenated styrene-butadiene-styrene graft maleic anhydride 0.5kg, stearic acid 0.5kg. The average molecular weight of the polyphenylene sulfide resin in this embodiment is 10000, but it is not limited thereto.

[0036] Its preparation method is as follows:

[0037] (1) Preparation of modified filler: 50 grams of hydroxy silicone oil, 10 grams of tetraethyl orthosilicate, 1 gram of dibutyltin dilauric acid, and 1000 grams of hexane were added to the flask and stirred at a speed of 300 r / min for 20 minutes to make it Mix well, then add 2000 g SiO 2 Continue to stir for 20 minutes, finally filter, wash and dry to obtain modified SiO 2 filler.

[0038] (2) Weigh the raw materials according to the ratio in the above ...

Embodiment 3

[0042] Corrosion-resistant, high-temperature-resistant, superhydrophobic polyphenylene sulfide composite material, its raw material ratio is as follows: polyphenylene sulfide resin 3kg; modified BaSO 4 3kg; polytetrafluoroethylene 1kg; silane coupling agent 2kg; ethylene-acrylate-glycidyl methacrylate terpolymer 0.5kg; stearic acid 0.5kg. The average molecular weight of polyphenylene sulfide resin in the present embodiment is 10000, and the melt flow index of ethylene-acrylate-glycidyl methacrylate terpolymer is 9g / 10min (190 ℃ / 2.16kg), but not only limited to this.

[0043] Its preparation method is as follows:

[0044](1) Preparation of modified filler: 50 grams of hydroxy silicone oil, 10 grams of tetraethyl orthosilicate, 1 gram of dibutyltin dilauric acid, and 1000 grams of hexane were added to the flask and stirred at a speed of 300 r / min for 20 minutes to make it Mix well, then add 2000 g BaSO 4 Continue to stir for 20 minutes, finally filter, wash and dry to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com