Genetically engineered bacterium for producing N-acetylneuraminic acid as well as construction and application of genetically engineered bacterium

A technology of genetically engineered bacteria and genes, applied in the field of genetic engineering, can solve problems such as inability to meet the needs of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

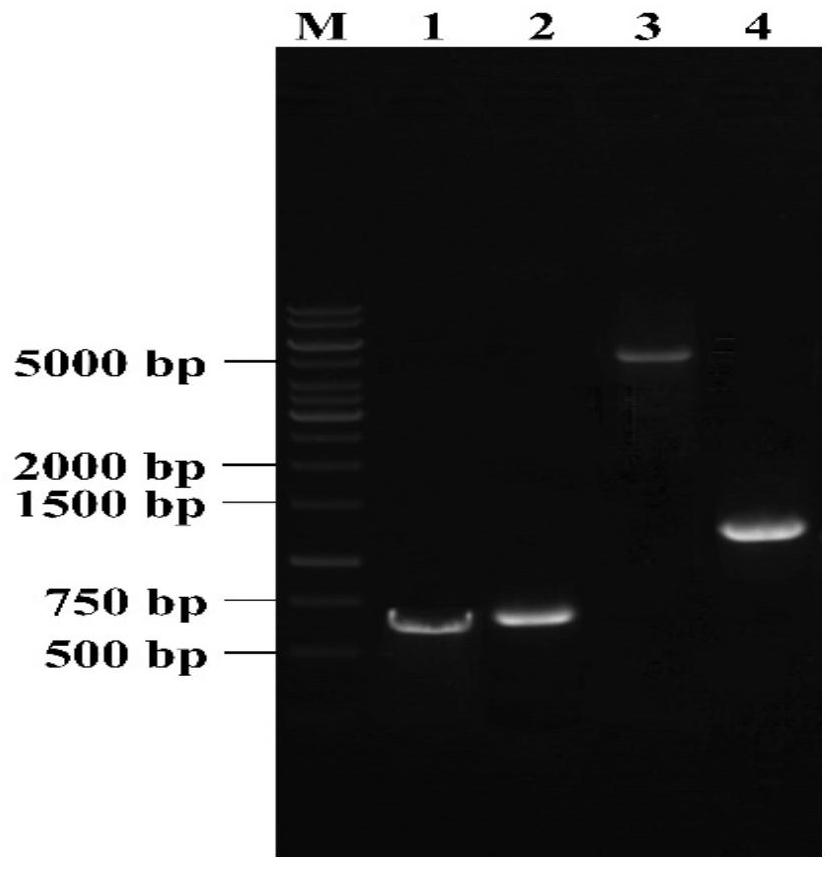

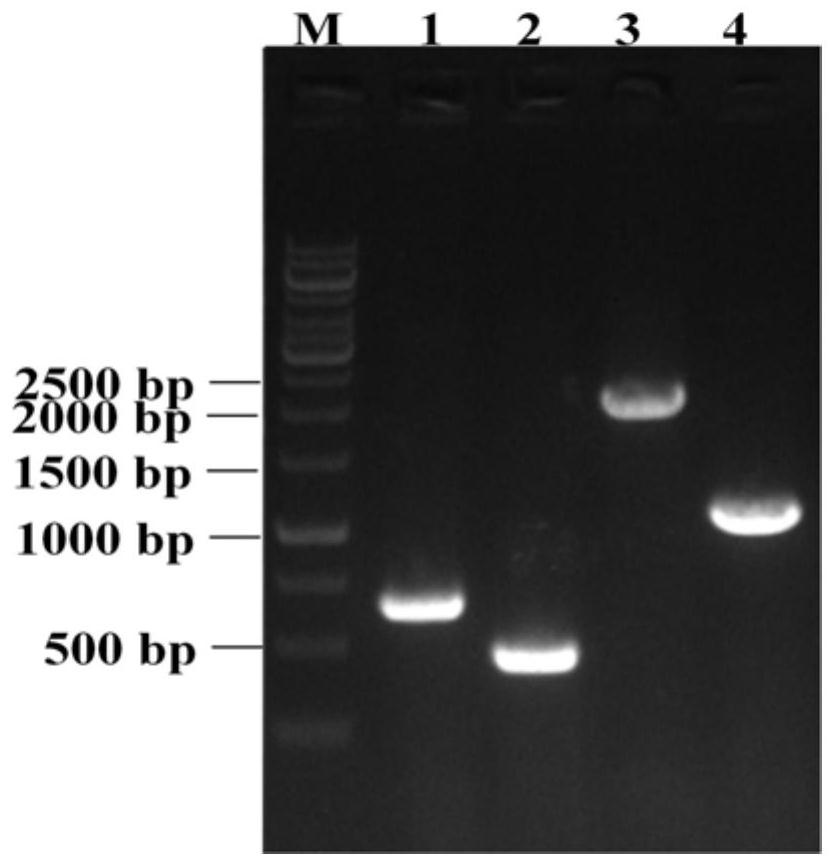

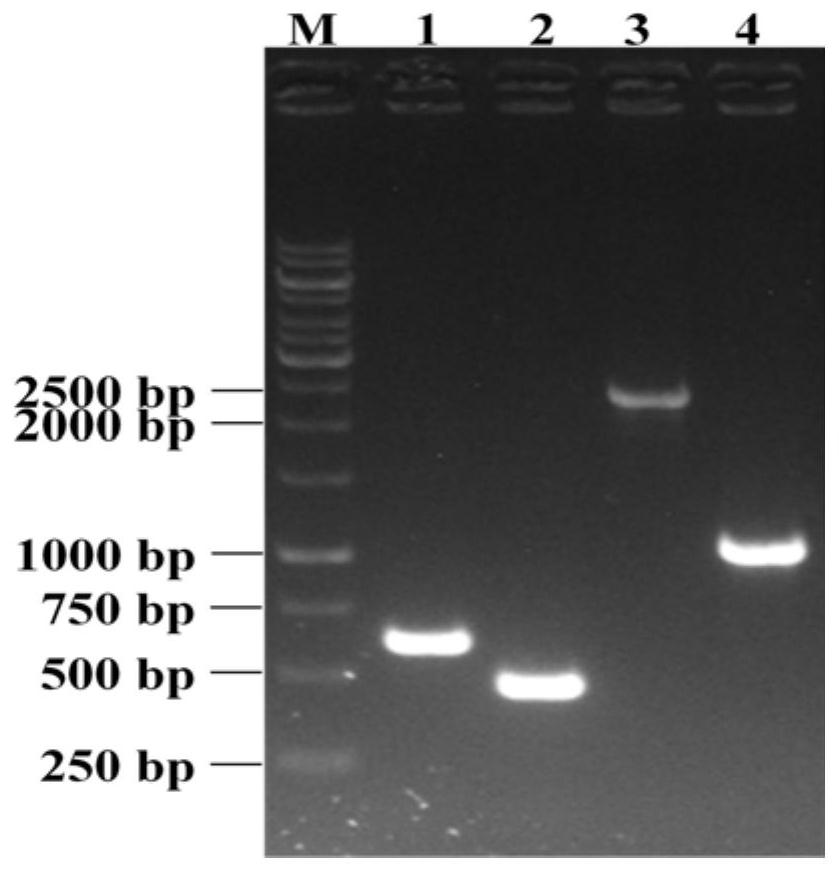

Image

Examples

Embodiment 1

[0051] Embodiment 1: Neu5Ac produces the construction of Escherichia coli genetically engineered bacteria

[0052] Directed gene modification using CRISPR / Cas9 gene editing technology. The gene editing method used in the present invention is carried out with reference to the literature (Li Y, Lin Z, Huang C, et al. Metabolic engineering of Escherichiacoli using CRISPR–Cas9 mediated genome editing. Metabolic engineering, 2015, 31:13-21.).

[0053] Some of the experimental methods involved are as follows:

[0054] (1) Construction of pGRB plasmid:

[0055] The target sequence (PAM:5'-NGG-3') was designed using CRISPR RGEN Tools for cleavage of the target gene. After synthesizing the forward primer and the reverse complementary primer, take 10 μL of each in a PCR tube, mix them evenly, and prepare a DNA fragment containing the target sequence by annealing single-stranded DNA. Reaction conditions: pre-denaturation at 95°C, 5min; annealing at 50°C, 1min. The obtained DNA fragme...

Embodiment 2

[0096] Example 2: A method for producing Neu5Ac using the strain constructed in Example 1 above as a production strain

[0097] (1) Slant surface activation culture: Take out the microbial strains stored at -80°C, inoculate them densely into the slant surface activation medium under sterile conditions, place them at 37°C for about 12 hours, and transfer them to the slant eggplant shape after the cultivation is completed. The bottle activation medium was subcultured once;

[0098] (2) Seed tank culture: Pour about 200mL of sterile water into an eggplant-shaped bottle near the flame of the ultra-clean bench, use an inoculation loop to scrape the colony into sterile water to prepare a bacterial suspension, and inoculate the bacterial suspension into the seed medium During the cultivation process, the pH was maintained at 7.0, the temperature was maintained at 37°C, and the dissolved oxygen was maintained at 30%, and the culture was carried out until the dry cell weight was 3g / L, ...

Embodiment 3

[0106] Example 3: A method for producing Neu5Ac using the strain constructed in Example 1 above as a production strain

[0107] (1) Slant surface activation culture: Take out the microbial strains stored at -80°C, inoculate them densely into the slant surface activation medium under sterile conditions, place them at 36°C for about 13 hours, and transfer them to the slant eggplant shape after the cultivation is completed. The bottle activation medium was subcultured once;

[0108] (2) Seed tank culture: Pour about 200mL of sterile water into an eggplant-shaped bottle near the flame of the ultra-clean bench, use an inoculation loop to scrape the colony into sterile water to prepare a bacterial suspension, and inoculate the bacterial suspension into the seed medium During the cultivation process, the pH was maintained at 7.2, the temperature was maintained at 36°C, and the dissolved oxygen was maintained at 25%, and the culture was carried out until the dry cell weight was 4g / L, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com