Strength inducer for low-temperature cement-based material

A technology of cement-based materials and inducers, which is applied in the field of strength inducers for low-temperature cement-based materials. It can solve the problems of expensive materials, uncertain use effects, and complex components of the components, so as to promote the rapid development of strength and low cost of use. , the effect of high early intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

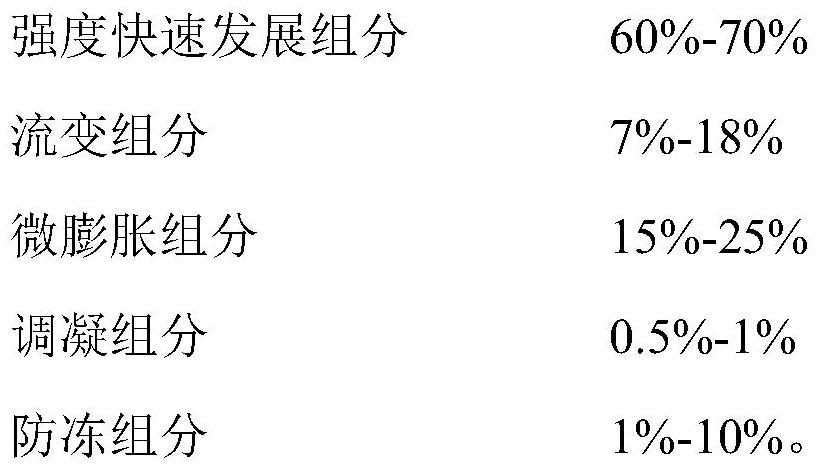

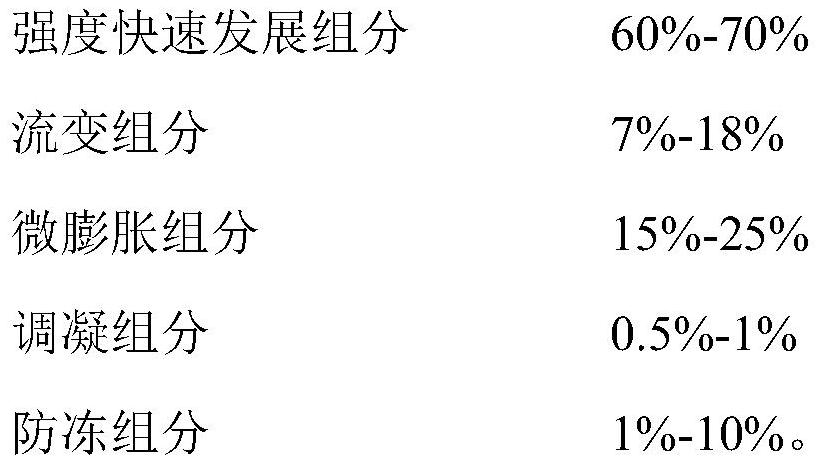

[0037] A cement-based material in the rapid development of the strength-inducing agent, the components and weight percentage: 60% of the intensity of the rapid development of component, component rheology 8%, 23% micro expandable components, congealing component 0.64% antifreeze component 8.36%.

[0038] The rapid development of strength of high alumina cement component, ground sulphoaluminate cement and mixed cement nuclei by 60:30:10; rheological component is silica fume; micro-expansion cast component; condensate transfer component tartaric acid and lithium 6: 4 mixture of both compounds are industrial grade; antifreeze component is industrial grade sodium.

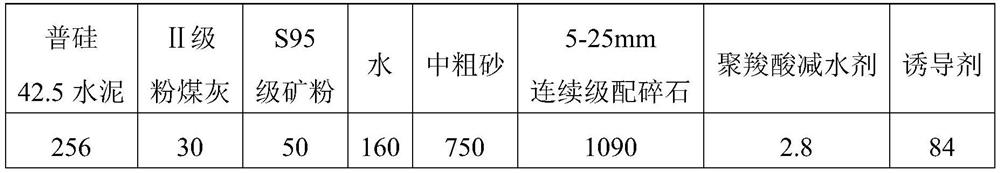

[0039] Volume embodiment inducer of the present embodiment is 20% of the powder materials, using the method of mixed use, the first inducing agent and other powder and sand, stone uniform dry mix, then add water and mix made superplasticizer concrete, immediately after the molding in-mold curing, were placed in -10 ℃, -5 ℃...

Embodiment 2

[0046] Syduners of rapid development of cement-based materials, their components and mass percentages: intensity rapid development components 65%, 15% of the rheology components, 15% of the dimensions, 0.82% lifting group, antifreeze The component is 4.18%.

[0047] The intensity rapid development component medium high aluminum cement, sulfoalosyl cement and grinding cement crystal nucleus are mixed by 70:15:15; the rheological components are divided into silica ash and fly ash to composite 40:60; micro The expansion group is divided into lightly expanded magnesium oxide; the lifting group is divided into tartaric acid and lithium carbonate, a carbonate, lithium carbonate is industrial grade compound; antifreeze group is divided into sodium formate, calcium carboxylate and sodium sulfate 45:45 : 10 composite, all three are industrial grade compounds.

[0048] In this embodiment, the induction amount of the inducer is 30% of the powder material. When used, an inner bone is used, fi...

Embodiment 3

[0054] A sungotent, a rapid development of cement-based material, has a component and mass percentage: a rapid development component of the intensity, 9% of the rheology component, 19% of the dimensions, 0.72% lifting components, antifreeze The component is 1.28%.

[0055] The intensity rapid development component is mixed with sulfate cement and grinding cement crystals in 80:20; the rheological components are compounded into silica ash to composite 80:20; the micro-expansion group is divided into azo compound It is formulated with the gypsum at 2:98; the lithogenic group is mixed into boric acid and lithium carbonate, boric acid, lithium carbonate is an industrial stage compound; the antifreeze component is sodium nitrate, which is an industrial stage compound.

[0056] In this example, the dosage of the induced agent is 30% of the powder material. When used, an inner bancy is used, and the inducer and other powder and sand are mixed, and then the water and water reducer are mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com