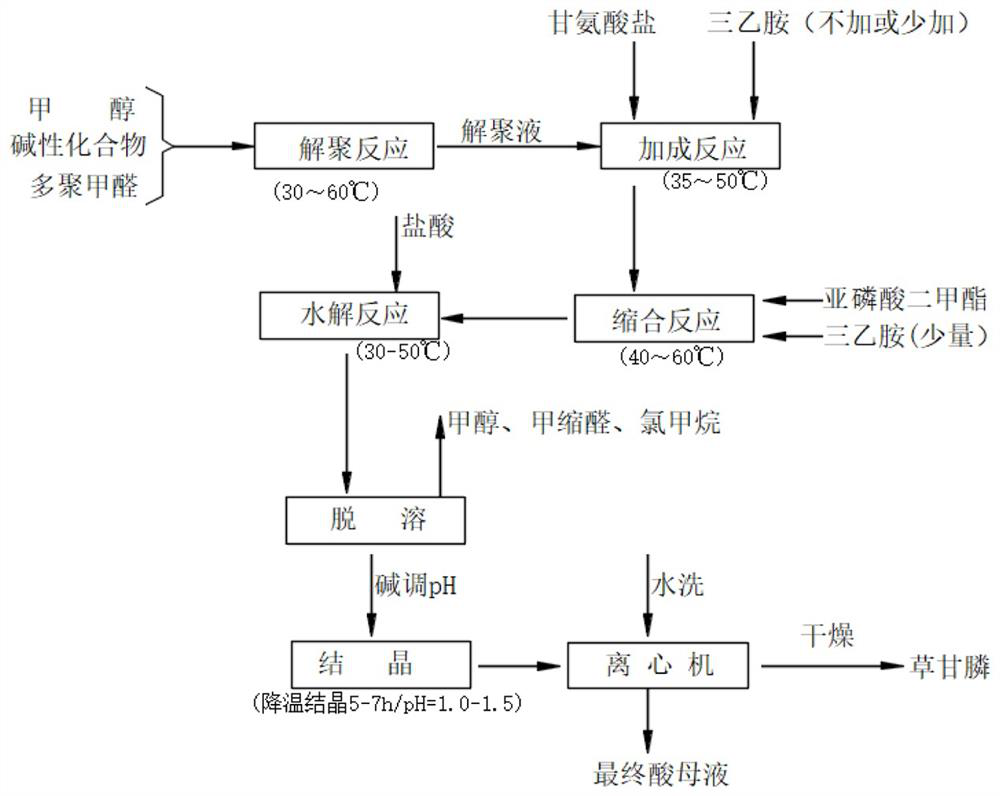

Process for synthesizing glyphosate by alkyl ester method

A technology of glyphosate and alkyl ester, which is applied in the field of glyphosate production by the alkyl ester method, can solve the problems of increasing the amount of mother liquor, hydrochloric acid and alkyl ester, etc., so as to reduce the amount of mother liquor, shorten the time, reduce The effect of steam elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

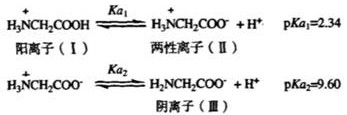

[0039] A synthetic method of glyphosate, comprising the steps of:

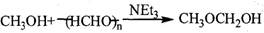

[0040] (1) Add 117ml of anhydrous methanol, 49g of paraformaldehyde, and 7.2g of caustic soda to a 1000ml four-neck flask, raise the temperature to 50°C and start the holding time. The holding temperature is 58-60°C. After holding for 20 minutes, add 225ml of methanol.

[0041] (2) After cooling down to below 35°C, add 62g of glycine (98.5% content) and 70g of triethylamine, and keep warm at below 40°C for 30min.

[0042] (3) Add 109g of dimethyl phosphite, start timing after heating up to 50°C, add 8g of triethylamine after 10 minutes of heat preservation, and the total heat preservation time is 70 minutes.

[0043] (4) After cooling down to 40°C, add 343g of 30% hydrochloric acid and keep the temperature below 40°C.

[0044] (5) Raise the temperature of the above hydrolyzate to 85°C and control it at 2.0-3.5h, 85-102°C at about 1.5h, at 102°C until the material turns yellow and control it at 1-1.5h, and con...

Embodiment 2

[0047] A synthetic method of glyphosate, comprising the steps of:

[0048] (1) Add 117ml of anhydrous methanol, 49g of paraformaldehyde, and 7.2g of caustic soda to a 1000ml four-neck flask, raise the temperature to 50°C and start the holding time. The holding temperature is 58-60°C. After holding for 20 minutes, add 225ml of methanol.

[0049] (2) After cooling down to below 35°C, add 80g of sodium glycinate (content 99%), add 10g of triethylamine, and keep warm at below 40°C for 30min.

[0050] (3) Add 109g of dimethyl phosphite, start timing after the temperature rises to 50°C, and the total holding time is 70min.

[0051] (4) After cooling down to 40°C, add 254g of 30% hydrochloric acid and keep the temperature below 40°C.

[0052] (5) Raise the temperature of the above hydrolyzate to 85°C and control it at 2.0-3.5h, 85-102°C at about 1.5h, at 102°C until the material turns yellow and control it at 1-1.5h, and control the end point temperature at 117°C. After the solutio...

Embodiment 3

[0055] A synthetic method of glyphosate, comprising the steps of:

[0056] (1) Add 117ml of anhydrous methanol, 49g of paraformaldehyde, and 7.2g of caustic soda to a 1000ml four-neck flask, raise the temperature to 50°C and start the holding time. The holding temperature is 58-60°C. After holding for 20 minutes, add 225ml of methanol.

[0057] (2) Add 80g of sodium glycinate (content 99%) after cooling down to below 35°C, and keep warm for 30min below 40°C.

[0058] (3) Add 100g of dimethyl phosphite, start timing when the temperature rises to 50°C, and the total holding time is 70min.

[0059] (4) After cooling down to 40°C, add 248g of 30% hydrochloric acid and keep the temperature below 40°C.

[0060] (5) Raise the temperature of the above hydrolyzate to 85°C and control it at 2.0-3.5h, 85-102°C at about 1.5h, at 102°C until the material turns yellow and control it at 1-1.5h, and control the end point temperature at 117°C. After the solution turns yellow, keep it warm fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com