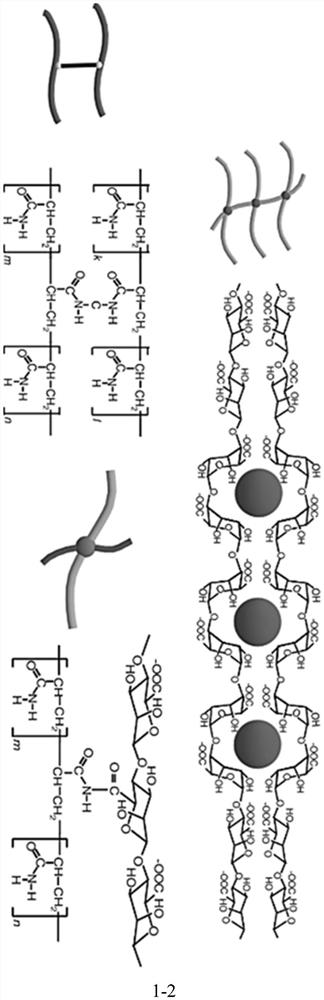

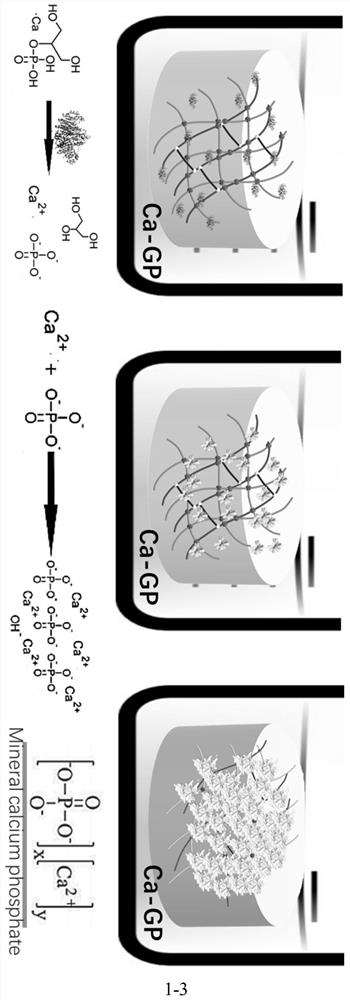

Multi-crosslinked high-strength enzyme-induced mineralized hydrogel and preparation method and application thereof

A multi-crosslinking, high-strength technology, applied in the field of medical materials, can solve the problems of low swelling stability, high brittleness of mineralized hydrogel, lack of osteogenic bioactivity, etc., to achieve improved mechanical properties, excellent comprehensive mechanical properties, The effect of great research value and clinical application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Use Ca 2+ , Zn 2+ 、Sr 2+ Preparation of crosslinked unmineralized pristine SA-PAM hydrogels

[0044] (1) Accurately weigh 2g sodium alginate (SA, purchased from Cologne) and 12g acrylamide (AM, purchased from Sigma), measure 80mL of deionized water in a beaker, dissolve AM in deionized water, add SA, place the beaker on a constant temperature water bath stirrer, heat at 45°C overnight until SA is completely dissolved, and record it as solution A.

[0045] (2) Prepare MBA and APS mother liquor: accurately weigh 0.1 g of MBA (methylenebisacrylamide, purchased from Sigma) powder and dissolve in 5 mL of deionized water; weigh 0.1 g of APS (ammonium persulfate, purchased from Sigma) The powder was dissolved in 1 mL of deionized water. The prepared two mother solutions were stored in the dark at room temperature, and were respectively recorded as solution B (MBA) and solution C (APS).

[0046] (3) Under the condition of stirring in a constant temperature water bath at...

Embodiment 2

[0058] 1. Use Ca 2+ 、Sr 2+ Preparation of cross-linked unmineralized SA-PAM hydrogels

[0059] (1) Accurately weigh 1.5g of sodium alginate (SA, purchased from Cologne) and 13.5g of acrylamide (AM, purchased from Sigma), measure 70mL of deionized water in a beaker, and dissolve AM in deionized water , add SA, place the beaker on a constant temperature water bath stirrer, heat at 37°C overnight until SA is completely dissolved, and record it as solution A.

[0060] (2) Prepare MBA and APS mother liquors: accurately weigh 0.15 g of MBA (methylene bisacrylamide, purchased from Sigma) powder and dissolve in 5 mL of deionized water; weigh 0.15 g of APS (ammonium persulfate, purchased from Sigma) The powder was dissolved in 1 mL of deionized water. The prepared two mother solutions were stored in the dark at room temperature, and were respectively recorded as solution B (MBA) and solution C (APS).

[0061] (3) Under the condition of stirring in a constant temperature water bath ...

Embodiment 3

[0073] 1. Use Ca 2+ , Zn 2+ 、Sr 2+ Preparation of cross-linked unmineralized SA-PAM hydrogels

[0074] (1) Accurately weigh 3g sodium alginate (SA, purchased from Cologne) and 12g acrylamide (AM, purchased from Sigma), measure 80mL of deionized water in a beaker, dissolve AM in deionized water, add SA, place the beaker on a constant temperature water bath stirrer, heat at 37°C overnight until SA is completely dissolved, and record it as solution A.

[0075] (2) Prepare MBA and APS mother liquor: accurately weigh 0.1 g of MBA (methylenebisacrylamide, purchased from Sigma) powder and dissolve in 5 mL of deionized water; weigh 0.1 g of APS (ammonium persulfate, purchased from Sigma) The powder was dissolved in 1 mL of deionized water. The prepared two mother solutions were stored in the dark at room temperature, and were respectively recorded as solution B (MBA) and solution C (APS).

[0076] (3) Under the condition of stirring in a constant temperature water bath at 37°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com