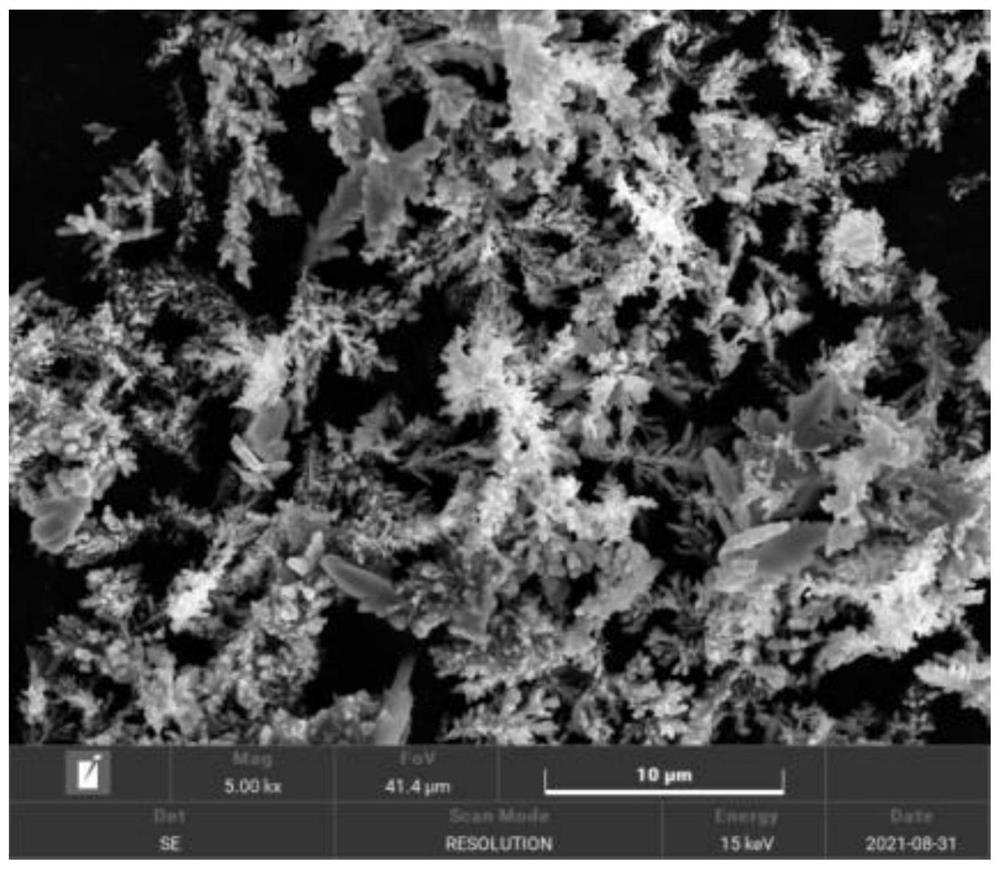

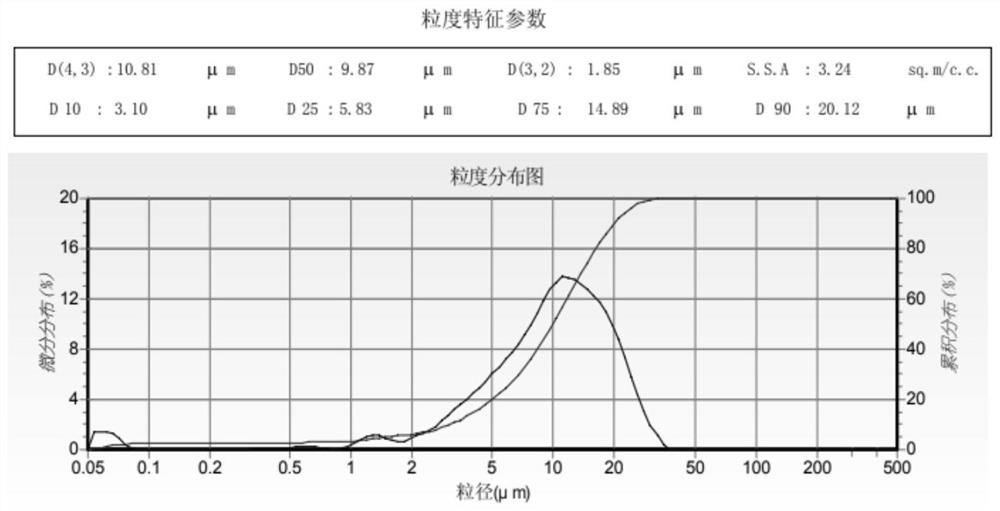

Preparation method for electronic-grade high-purity low-apparent-density dendritic copper powder

A low bulk ratio, dendritic technology, applied in the field of functional powder material preparation, can solve the problems of uneven particles, low yield, low added value, etc., and achieves high technological content, simple process flow and strong oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: A kind of preparation method of electronic grade high-purity low-porosity dendritic copper powder, concrete steps are as follows:

[0029] (1) Add the aluminum powder to the electrolyte, and make part of the aluminum powder react with the copper ions in the electrolyte for 1 minute to generate copper seeds, and the remaining aluminum powder will carry out the in-situ displacement reaction with the subsequent electrolysis reaction to improve the electrolysis efficiency; The electrolyte contains H 2 SO 4 30g / L, Cu 2+ 15g / L, HCl 0.6ml / L, NaCl 0.045g / L, dispersant PEG400 1.3g / L; the amount of aluminum powder added is 1.5g / L;

[0030] (2) Use pure copper anode plate and pure aluminum cathode plate to electrolyze in an electrolyte solution containing aluminum powder, and collect powdery deposits on the cathode plate; wherein the current density is 200A / m 2 , The pole spacing is 3cm, the system temperature is 20°C, and the powder brushing cycle is 15min;

[...

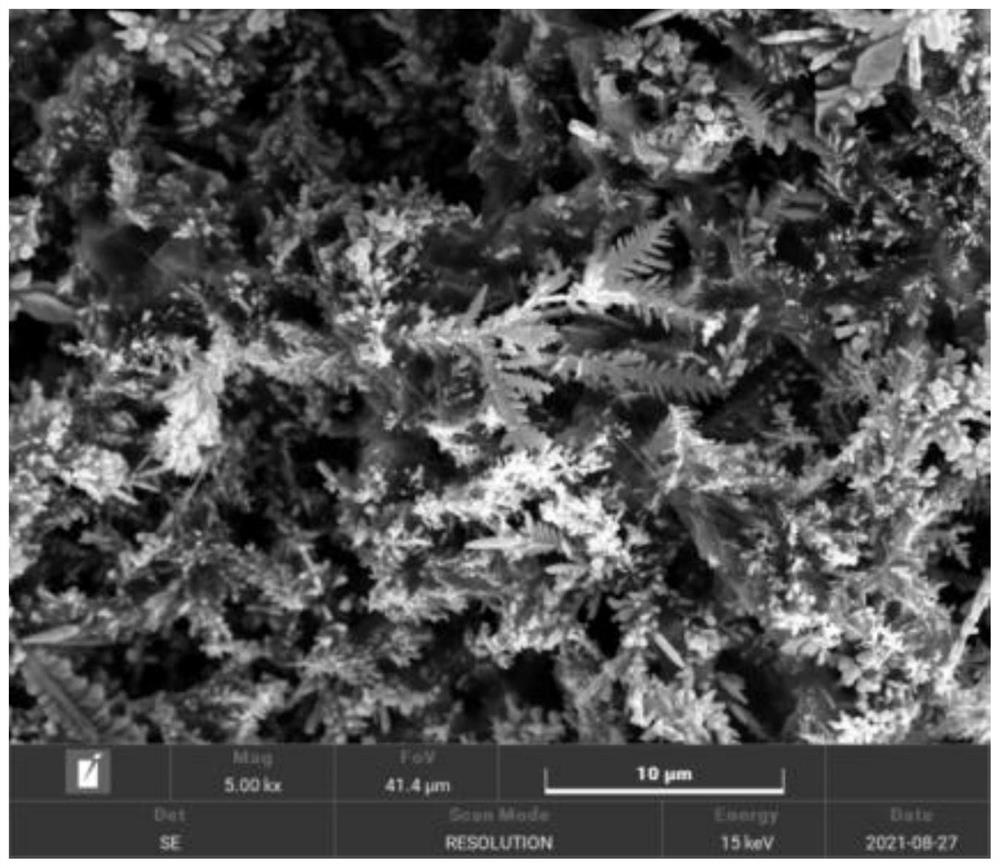

Embodiment 2

[0035] Embodiment 2: A kind of preparation method of electronic grade high-purity low-porosity dendritic copper powder, concrete steps are as follows:

[0036] (1) Add the zinc powder into the electrolyte, and make part of the zinc powder and the copper ions in the electrolyte replace and react for 10 minutes to generate copper seeds, and the remaining zinc powder carries out the in-situ replacement reaction with the subsequent electrolysis reaction to improve the electrolysis efficiency; The electrolyte contains H 2 SO 4 30g / L, Cu 2+ 15g / L, HCl 0.6ml / L, NaCl 0.045g / L, dispersant PEG400 1.3g / L; the amount of zinc powder added is 0.75g / L;

[0037] (2) Use pure copper anode plate and pure aluminum cathode plate to electrolyze in an electrolyte solution containing zinc powder, and collect powdery deposits on the cathode plate; wherein the current density is 300A / m 2 , The pole spacing is 5cm, the system temperature is 25°C, and the powder brushing cycle is 30min;

[0038] (3...

Embodiment 3

[0042] Embodiment 3: A kind of preparation method of electronic grade high-purity low-porosity dendritic copper powder, concrete steps are as follows:

[0043](1) Formaldehyde is added to the electrolyte, so that part of the formaldehyde reacts with the copper ions in the electrolyte for 10 minutes to form copper seeds, and the remaining formaldehyde is reduced in situ with the subsequent electrolysis reaction to improve the electrolysis efficiency; Contains H 2 SO 4 30g / L, Cu 2+ 15g / L, HCl 0.6ml / L, NaCl 0.045g / L, dispersant PEG400 1.3g / L; the amount of formaldehyde added is 1.25g / L;

[0044] (2) Use pure copper anode plate and pure aluminum cathode plate to electrolyze in an electrolyte containing formaldehyde, and collect powdery deposits on the cathode plate; wherein the current density is 100A / m 2 , The pole spacing is 5cm, the system temperature is 22°C, and the powder brushing cycle is 15min;

[0045] (3) In the cleaning tank, the powdery sediment is washed with dei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com