Low-cost Prussian white material and preparation method and application thereof

A Prussian white, low-quality technology, applied in the field of low-cost Prussian white materials and its preparation, can solve the problems of low actual capacity, high sodium deficiency, and high manufacturing cost, and achieve high capacity, increased sodium content, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

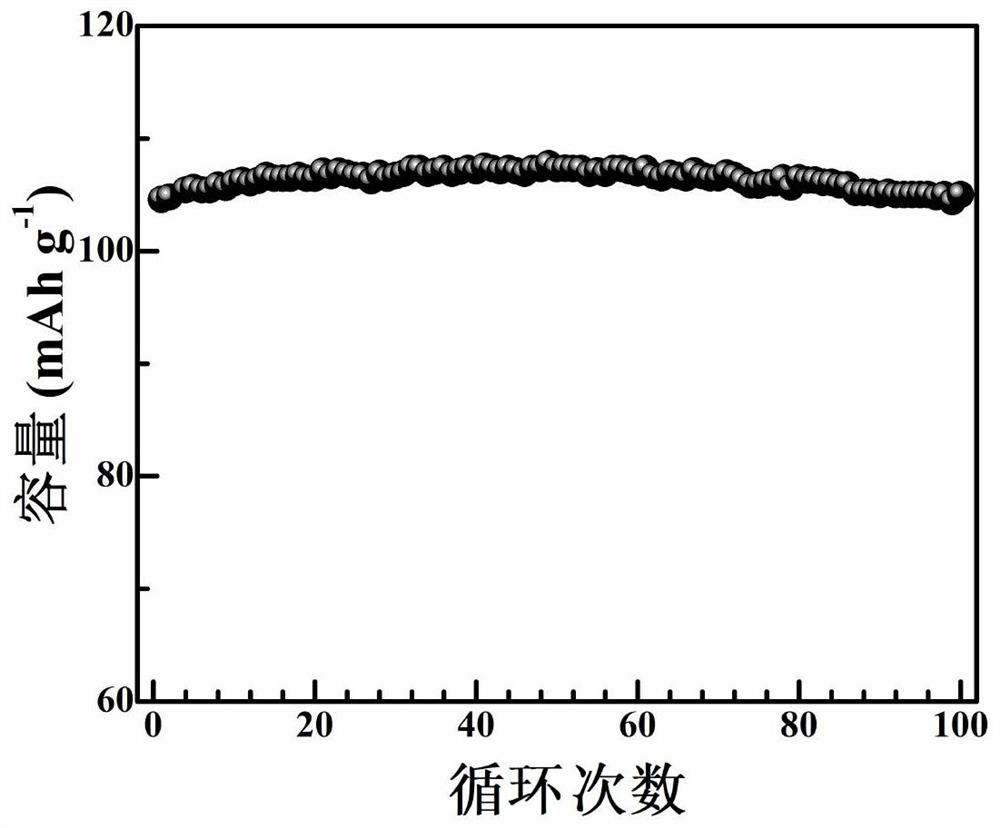

[0034] Dissolving sodium ferrocyanide decahydrate in tap water to obtain a solution I with a concentration of 0.3mol / L; dissolving manganese sulfate monohydrate, zinc sulfate heptahydrate, and sodium citrate in tap water to obtain manganese sulfate monohydrate and heptahydrate Solution II with a total concentration of zinc sulfate of 0.3 mol / L, wherein the molar ratio of manganese sulfate monohydrate and zinc sulfate heptahydrate is 9:1, the ratio of the moles of sodium citrate to the total moles of manganese sulfate monohydrate and zinc sulfate heptahydrate The ratio is 4:1; mix solution I and solution II, and obtain a suspension by co-precipitation at 60°C; age the suspension at 60°C for 4 hours, add sodium thiosulfate during the aging process, and add The molar ratio of the molar amount of manganese sulfate monohydrate and zinc sulfate heptahydrate is 1:1; finally, it is centrifuged with tap water and dried in vacuum at 110°C to obtain the Prussian white material. The Pruss...

Embodiment 2

[0044] Dissolve sodium ferrocyanide decahydrate in river water to obtain a solution I with a concentration of 0.2mol / L; dissolve manganese sulfate monohydrate, nickel sulfate hexahydrate, and sodium citrate in river water to obtain manganese sulfate monohydrate and hexahydrate Solution II with a total concentration of nickel sulfate of 0.2mol / L, wherein the molar ratio of manganese sulfate monohydrate and nickel sulfate hexahydrate is 8:1, the ratio of the moles of sodium citrate to the total moles of manganese sulfate monohydrate and nickel sulfate hexahydrate The ratio is 3:1; mix solution I and solution II, and obtain a suspension by co-precipitation at 60°C; age the suspension at 60°C for 4 hours, add sodium iodide during the aging process, and add mole The ratio of the amount of manganese sulfate to the total molar amount of manganese sulfate monohydrate and nickel sulfate hexahydrate is 1:1; finally, it is centrifuged in river water and dried in vacuum at 110°C to obtain ...

Embodiment 3

[0046] Dissolve sodium ferrocyanide decahydrate in seawater to obtain a solution I with a concentration of 0.4mol / L; dissolve manganese sulfate monohydrate, copper sulfate pentahydrate, and sodium citrate in seawater to obtain manganese sulfate monohydrate and pentahydrate Solution II with a total concentration of copper sulfate of 0.4mol / L, wherein the molar ratio of manganese sulfate monohydrate and copper sulfate pentahydrate is 10:1, the ratio of the moles of sodium citrate to the total moles of manganese sulfate monohydrate and copper sulfate pentahydrate The ratio is 5:1; mix solution I and solution II, and obtain a suspension by co-precipitation at 60°C; age the suspension at 60°C for 4 hours, add sodium tetrathionate during the aging process, and add The ratio of the molar amount to the total molar amount of manganese sulfate monohydrate and copper sulfate pentahydrate is 1:1; finally, it is centrifuged with sea water and dried in vacuum at 110°C to obtain the Prussian ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com