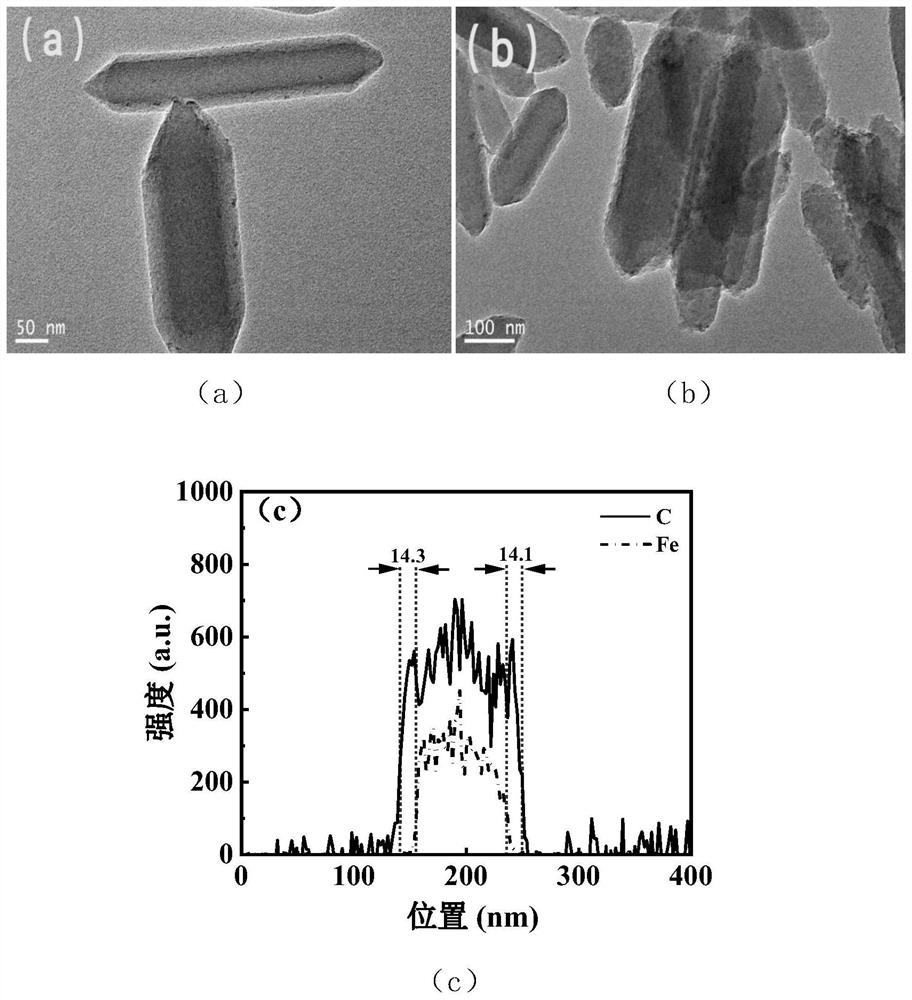

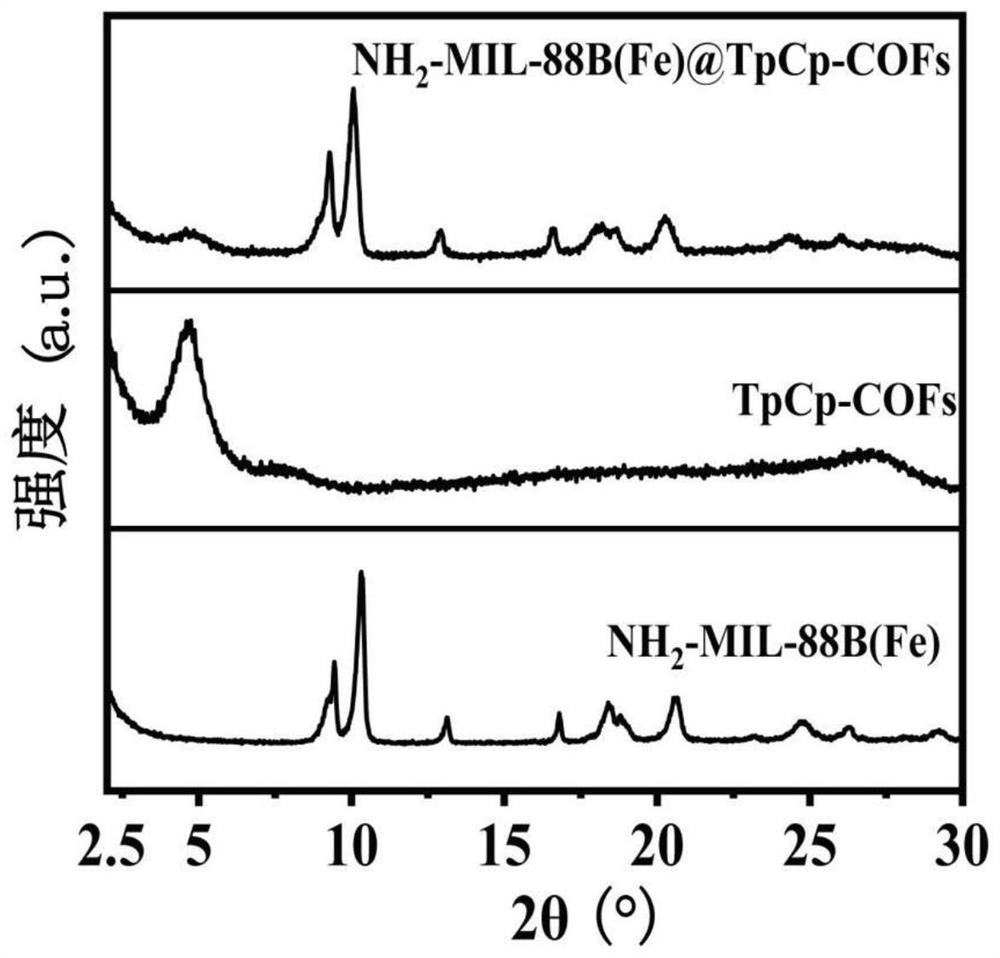

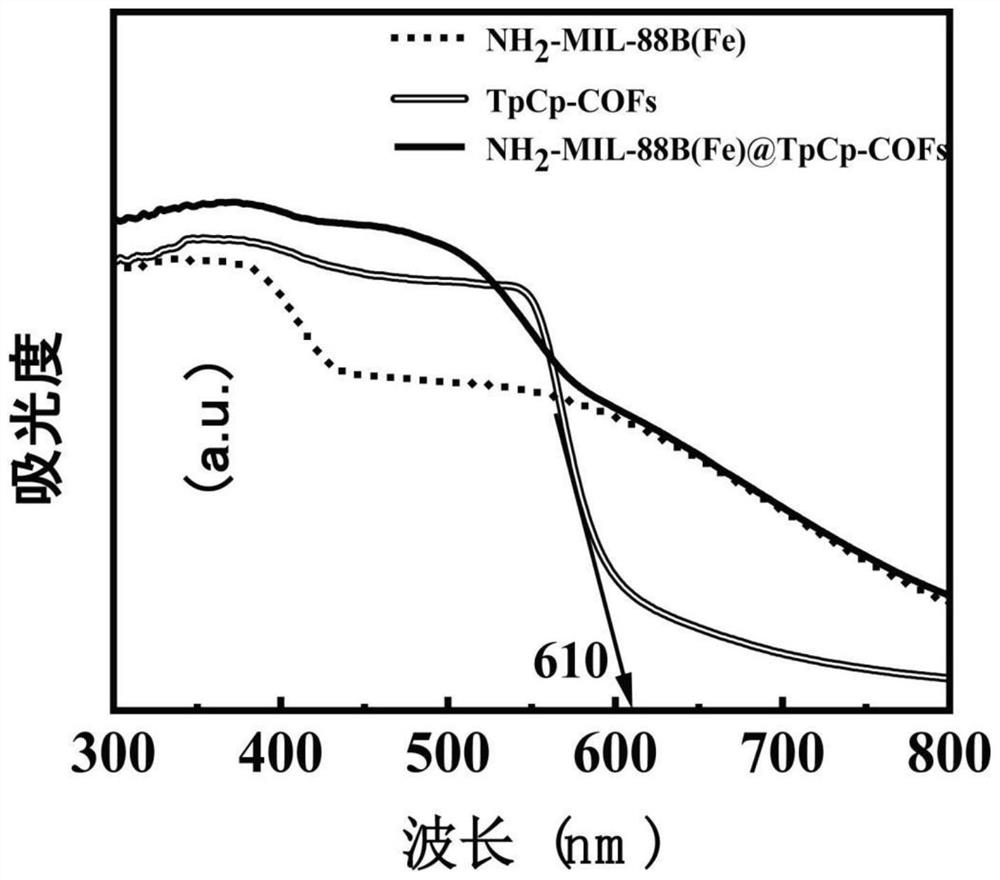

NH2-MIL-88B (Fe)@TpCp-COFs core-shell composite photo-Fenton catalyst and preparation method thereof

A composite light and catalyst technology, applied in the field of photocatalysis, to achieve the effect of improving separation efficiency, high catalytic activity, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiments of the present invention provide a kind of NH 2 -The preparation method of MIL-88B(Fe)@TpCp-COFs core-shell composite photo-Fenton catalyst, comprising the following steps:

[0026] S1: Take FeCl 3 ·6H 2 O (Sinopharm Chemical Reagent Co., Ltd., the same below), poloxamer (Aladdin Biochemical Technology Co., Ltd., the same below), glacial acetic acid (Aladdin Biochemical Technology Co., Ltd., the same below), 2-amino-p-benzene Diformic acid (Bailingwei Technology Co., Ltd., the same below) was fully dissolved in 65 mL of deionized water, and then placed in a polytetrafluoroethylene-lined hydrothermal reaction kettle. Among them, the iron ion concentration was 45mmol / L; the poloxamer concentration was 10.7g / L; the glacial acetic acid concentration was 21g / L; the 2-aminoterephthalic acid concentration was 21.7mmol / L. Put the hydrothermal reaction kettle in a forced air drying oven and keep it warm at 100°C for 20 hours. After the reaction, take out the hydro...

Embodiment 2

[0033] Embodiments of the present invention provide a kind of NH 2 -The preparation method of MIL-88B(Fe)@TpCp-COFs core-shell composite photo-Fenton catalyst, comprising the following steps:

[0034] S1: Take FeCl 3 ·6H 2 O, poloxamer, glacial acetic acid and 2-aminoterephthalic acid were fully dissolved in 65 mL of deionized water, and placed in a polytetrafluoroethylene-lined hydrothermal reaction kettle. Among them, the iron ion concentration was 45mmol / L; the poloxamer concentration was 10.7g / L; the glacial acetic acid concentration was 21g / L; the 2-aminoterephthalic acid concentration was 21.7mmol / L. Put the hydrothermal reaction kettle in a forced air drying oven and keep it warm at 100°C for 22 hours. After the reaction, take out the hydrothermal reaction kettle and cool it to room temperature naturally, and wash the product in it with N,N-dimethylformamide. After filtering, place it in a vacuum oven at 60°C and dry it to constant weight to obtain NH 2 - MIL-88B(Fe...

Embodiment 3

[0041] Embodiments of the present invention provide a kind of NH 2 -The preparation method of MIL-88B(Fe)@TpCp-COFs core-shell composite photo-Fenton catalyst, comprising the following steps:

[0042] S1: take FeCl 3 ·6H 2 O, poloxamer, glacial acetic acid and 2-aminoterephthalic acid were fully dissolved in 65 mL of deionized water, and placed in a polytetrafluoroethylene-lined hydrothermal reaction kettle. Among them, the iron ion concentration was 45mmol / L; the poloxamer concentration was 10.7g / L; the glacial acetic acid concentration was 21g / L; the 2-aminoterephthalic acid concentration was 21.7mmol / L. Put the hydrothermal reaction kettle in a forced air drying oven and keep it warm at 100°C for 23 hours. After the reaction, take out the hydrothermal reaction kettle and cool it to room temperature naturally, and wash the product in it with N,N-dimethylformamide. After filtering, place it in a vacuum oven at 60°C and dry it to constant weight to obtain NH 2 - MIL-88B(Fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com