Ion chelating wood preservative treatment method based on weak phase structure enhancement

A wood preservative and treatment method technology, applied in wood treatment, wood treatment details, impregnated wood, etc., can solve the problems of short timeliness, easy biodegradation, affecting the timeliness and performance of organic wood preservatives, etc., to achieve low cost and enhanced Chelation and passivation, the effect of delaying decay and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

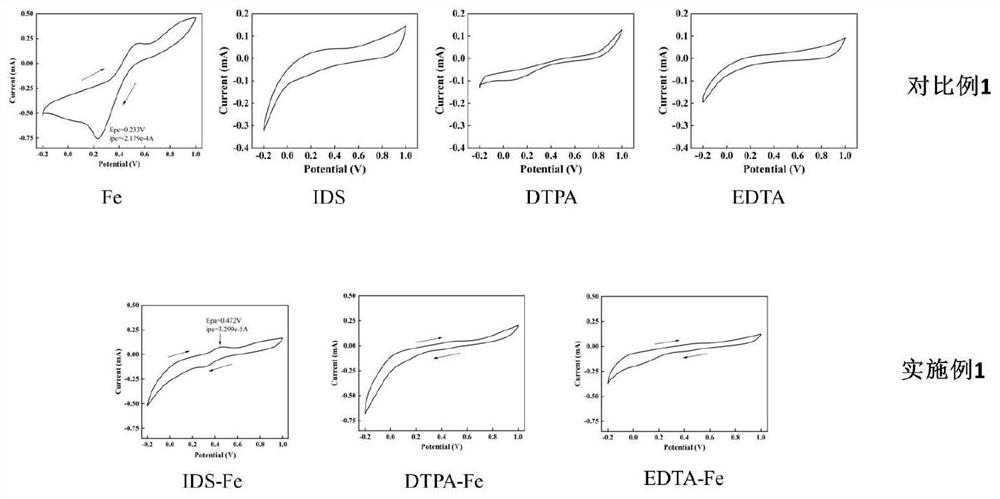

[0046] Using FeCl 3 ·H 2 O with 20mM Fe 3+ solution; use IDS to prepare 50mM IDS solution; use DTPA to prepare 15mM DTPA solution; use EDTA to prepare 50mM EDTA solution. Take 20mL20mM Fe 3+ solution, add 8mL 50mM EDTA, then add 52mL water, configure Fe 3+ -EDTA (1:1) solution; take 20mL 20mM Fe 3+ solution, add 26.67mL15mM DTPA, then add 33.33mL water, configure Fe 3+ -DTPA (1:1) solution; take 20mL 20mM Fe 3+ solution, add 8mL 50mM IDS, then add 52mL water, configure Fe 3+ - IDS (1:1) solution. Take an appropriate amount of the prepared solution in the electrolytic cup, insert the electrode, and test the redox peak current and point position of the sample solution.

Embodiment 2

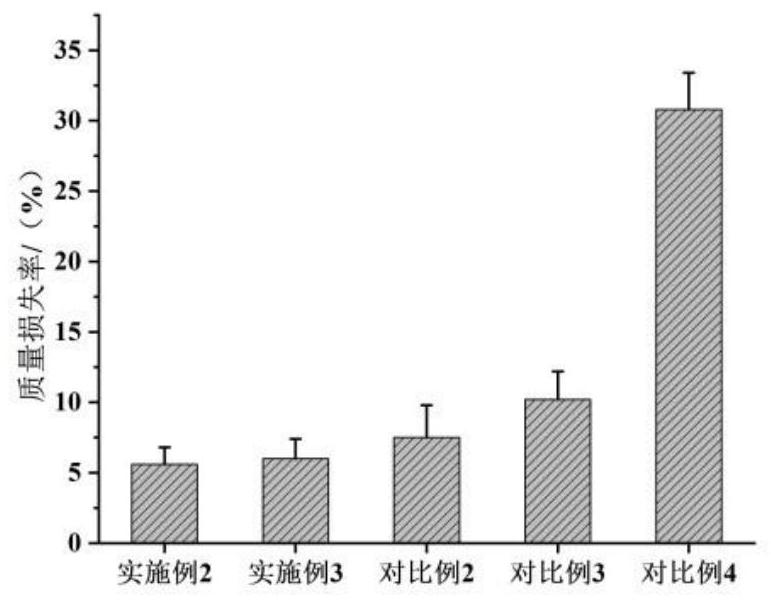

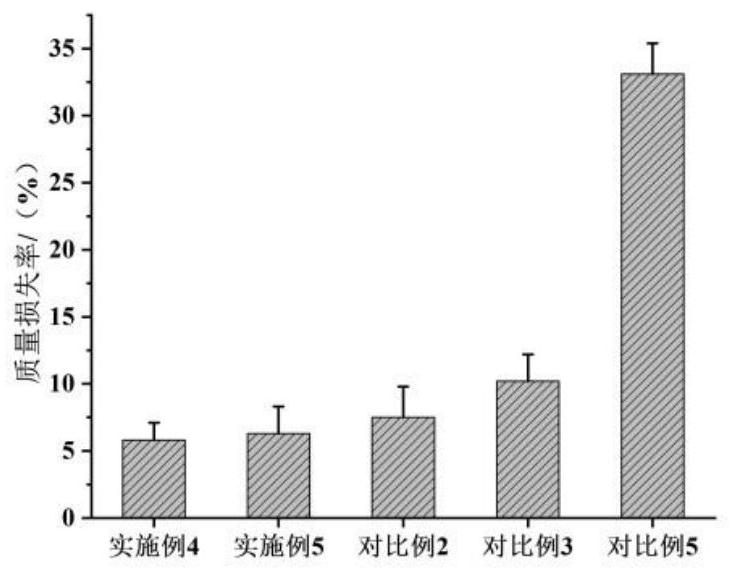

[0051] This implementation case involves the preparation and use of an ion-chelating preservative, including: 1 part of 4,5-dichloro-2-n-octyl-3-isothiazolinone EC, 0.1 part of tetrasodium iminodisuccinate Salt, 0.05 part of defoamer, 0.05 part of stabilizer, 0.05 part of penetrant, and the rest is water. The defoamer is polyether; the stabilizer is sodium ethylenediamine tetramethylene phosphonate, sodium thiosulfate, isopropylacrylamide and ethanolamine, among which sodium ethylenediamine tetramethylene phosphonate, sodium thiosulfate, The weight ratio of isopropyl acrylamide and ethanolamine is 20%, 30%, 40%, 10% of the total amount of the stabilizer; the penetrating agent is fatty alcohol polyoxyethylene ether.

[0052] The specific preparation method is as follows: Weigh 11.11g of 4,5-dichloro-2-n-octyl-3-isothiazolinone emulsifiable concentrate and dissolve it in an appropriate amount of water, add stabilizer, penetrant, defoamer, add 1g of iminodisuccinate Acid tetraso...

Embodiment 3

[0057] This implementation case involves the preparation and use of an ion-chelating wood preservative, including: 1 part of 4,5-dichloro-2-n-octyl-3-isothiazolinone EC, 0.1 part of iminodisuccinic acid Tetrasodium salt, 0.05 part of defoamer, 0.05 part of stabilizer, 0.05 part of penetrant, and the rest is water. Defoamer, stabilizer, penetrating agent kind and consumption are identical with embodiment 2.

[0058] The specific preparation method is as follows: Weigh 11.11g of 4,5-dichloro-2-n-octyl-3-isothiazolinone emulsifiable concentrate and dissolve it in an appropriate amount of water, add a stabilizer, penetrant, and defoamer, and add 1g of Tetrasodium succinate, mix well, add water to 2000g, heat to 40°C, stir with a stirrer for 10min at a speed of 200-1000r / min, and obtain the preservative after completion. Put the masson pine wood in the impregnation tank, vacuumize to -0.09MPa for 10-30min, then inject the preservative, pressurize to 0.4-0.5MPa, and hold the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com