Thin film type semiconductor chip structure and photoelectric device using same

A chip structure and semiconductor technology, applied in the direction of semiconductor devices, semiconductor lasers, optical waveguide semiconductor structures, etc., can solve the problems of current congestion, quantum efficiency, unresolved and insufficient sidewall light escape, and achieve suppression of non-radiative recombination heating , Improve light extraction efficiency and low device internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

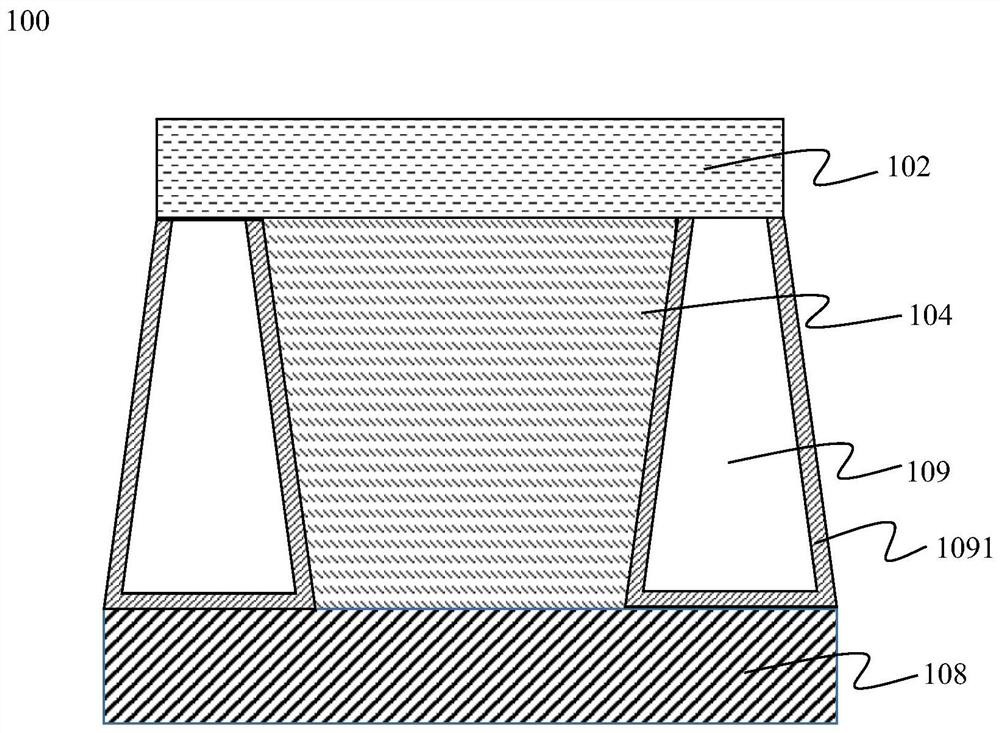

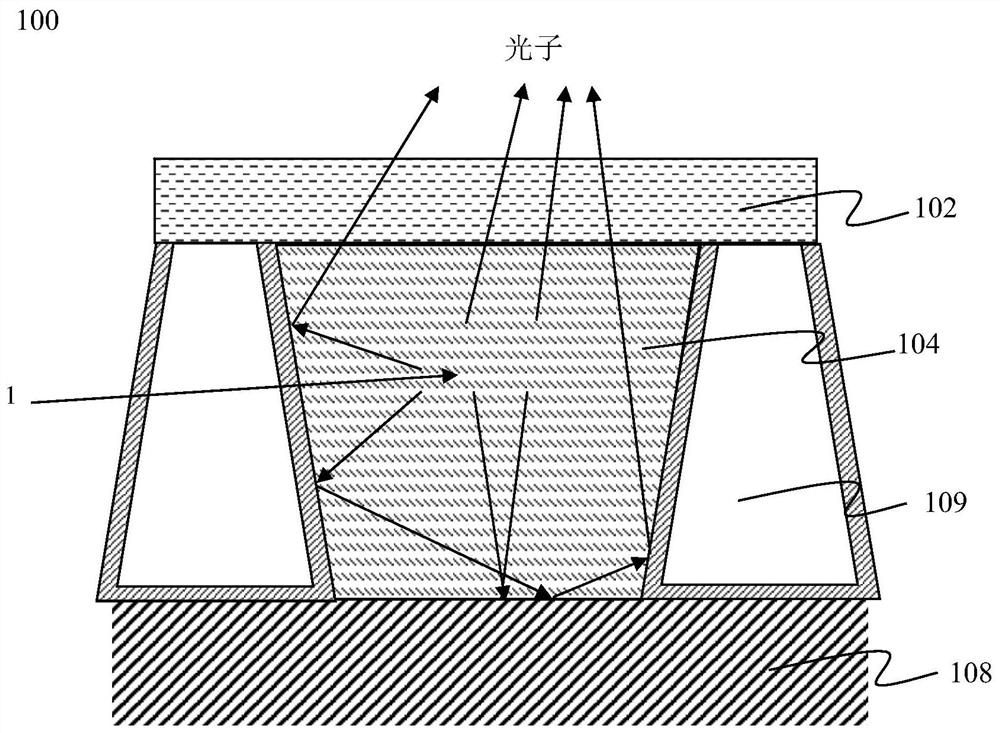

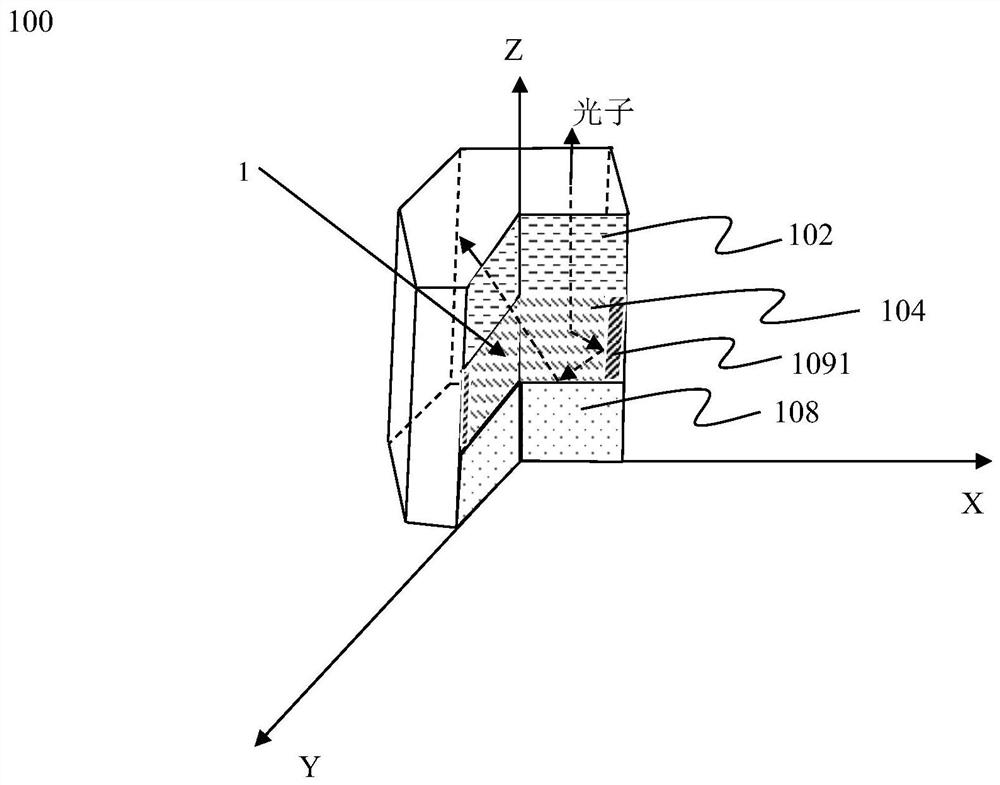

[0071] like figure 1 As shown, the thin film semiconductor chip structure according to Embodiment 1 of the present invention may be composed of one or more optical lattices 100 . The optical grid 100 includes a metal substrate 108 and a metal side wall 109 used as an electrode, and the metal substrate 108 and the metal side wall 109 are insulated and connected to each other to form an optical reflection cavity 1 (such as Figure 2A and 2B shown); the top of the optical reflective cavity 1 is covered with the first transparent conductive layer 102, and the first transparent conductive layer 102 is electrically connected with the metal sidewall 109, so that the optical grid 100 forms a closed structure. like Figure 2A and Figure 2B As shown, under the reflection of the metal substrate 108 and the metal sidewall 109, the photons can only pass through the first transparent conductive layer 102 on the top of the optical cell to exit. Inside the optical lattice, a photoelectri...

Embodiment 2

[0079] According to the attached Image 6 Another embodiment of the present disclosure will be described in detail.

[0080] Embodiment 2 is another specific implementation based on Embodiment 1. The optical grid 200 uses an epitaxial thin film layer to further improve the conversion efficiency of converting electrical energy into light energy, and finally increase the light extraction rate. It should be noted that the thin film layer with an epitaxial structure refers to a thin film layer grown on a substrate using an epitaxial process.

[0081] like Image 6 As shown, the photoelectric conversion layer adopts the multi-quantum well light-emitting layer 204 that converts electrical energy into light energy, and forms an electrical connection in series between the first transparent conductive layer 202 and the metal substrate 208 from top to bottom: the first current The confinement layer 203, the multi-quantum well light-emitting layer 204, the second current confinement la...

Embodiment 3

[0090] According to the attached Figure 7 Another embodiment disclosed in the present invention will be described in detail.

[0091] Arranging a plurality of light grids in Embodiment 2 together constitutes a "light grid array", which can be in a honeycomb shape. The whole device is a honeycomb light-emitting structure formed by the aggregation of many optical grids 200. The size of the optical grids in the honeycomb structure can be controlled by photolithography precision; preferably, the size of the light-emitting surface of each optical grid ranges from 10 μm to 500 μm, which can Extremely low internal resistance of the device to achieve high efficiency of electrical injection; the honeycomb structure has a three-dimensional reflective structure, which only retains the light emitted from the surface of the device, and at the same time eliminates the shading effect of the metal electrodes on the surface, plus the anti-reflection of the multi-layer structure on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com