Basalt fiber/polypropylene composite material based on surface roughening and interface enhancement and preparation method of basalt fiber/polypropylene composite material

A basalt fiber and surface roughening technology, which is applied in the field of basalt fiber/polypropylene composite material and its preparation, can solve the problems of difficulty in ensuring the shedding, deterioration of the excellent performance of basalt fiber, and the deterioration of basalt fiber performance, so as to improve the contact area and mutual force, enhance the interface mechanical interlock, and promote the effect of epigenetic crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of preparation method based on the basalt fiber / polypropylene composite material that surface roughening interface strengthens, comprises the following steps:

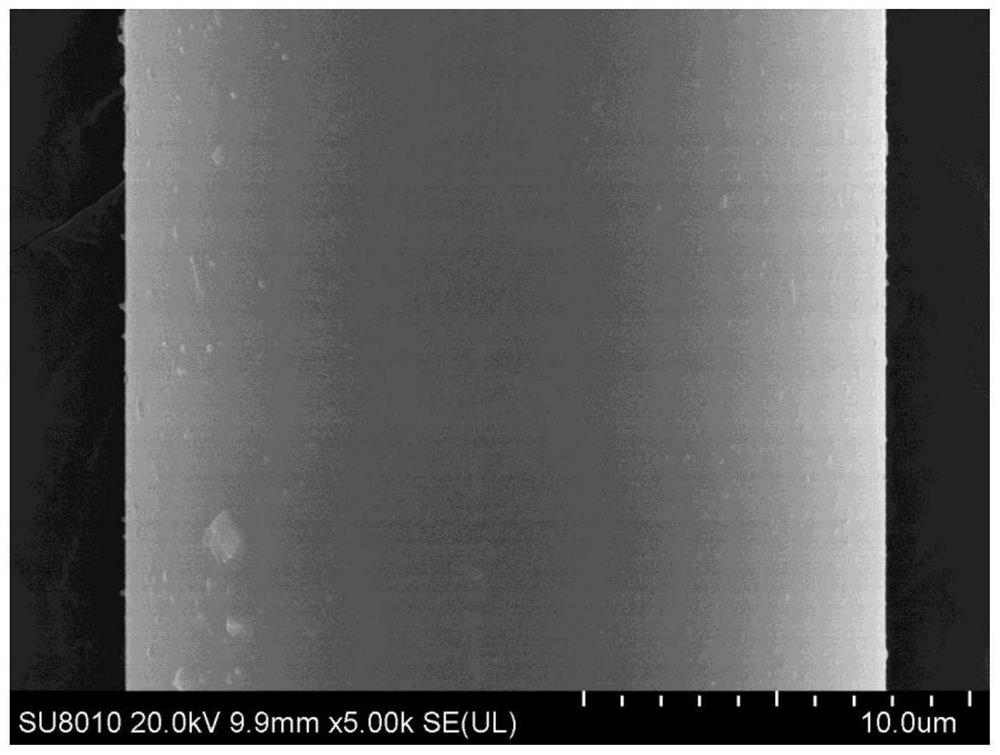

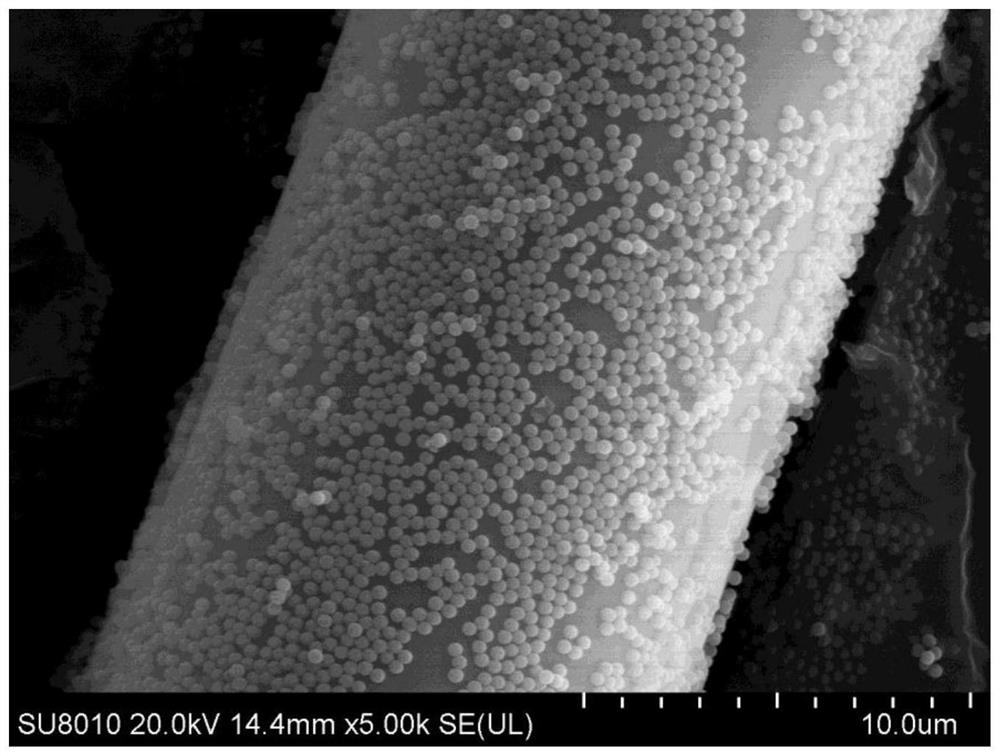

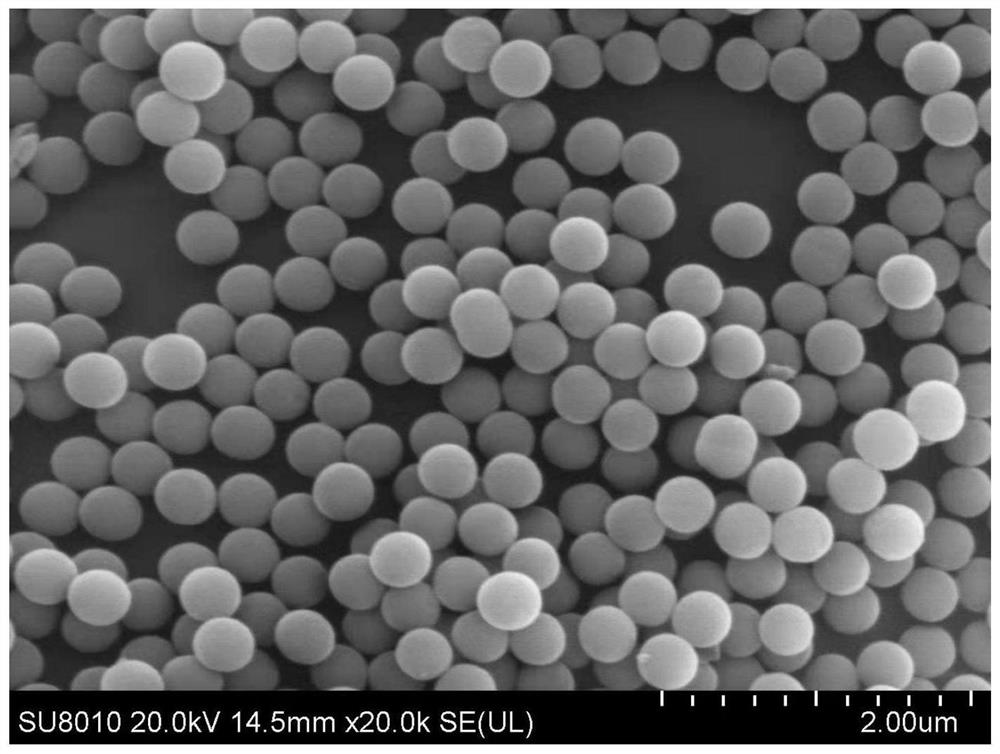

[0037](1) Take basalt fibers (fiber diameter 13 μm, length 12mm) and heat-treat them at 300°C for 30 minutes to remove the sizing agent and other organic impurities coated during spinning; then dilute acrylic acid with absolute ethanol (more than 99.5vol%) into Acrylic acid solution with a mass fraction of 50wt%, heat-treated basalt fibers were added to the acrylic acid solution at 15wt% of the mass of the acrylic acid solution, stirred at 200 rpm for 1 hr, then left to stand for 1 hr, filtered and placed in a constant temperature drying oven at 80 ° C for 6 hr to obtain Acrylic treated basalt fiber, its scanning electron microscope picture is shown in figure 1 ;

[0038] (2) The basalt fibers treated with acrylic acid are subjected to electron beam irradiation treatment in air atmosphere, and the irradi...

Embodiment 2-13

[0045] Embodiments 2-13 are based on Embodiment 1, and some process parameters have been modified and adjusted. Table 1 shows the process parameters that are different from Embodiment 1 in each embodiment.

[0046] The processing parameter of table 1 embodiment 2-13

[0047]

[0048]

[0049] In Table 1, "-" represents the same as Example 1.

[0050] The performance test results of the above-mentioned embodiments 2-13 are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com