Wrapping film material and preparation method thereof

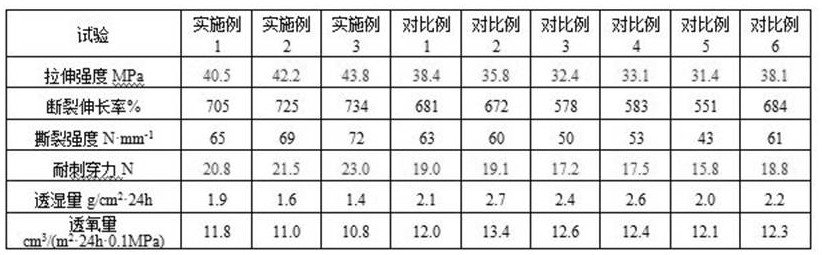

A stretch film and material technology, applied in chemical instruments and methods, other household appliances, household components, etc., can solve the problem of stretch film material tensile strength, poor puncture resistance, unstable film production, uneven product quality, etc. problems, to achieve the effects of compact inner layer structure, improved mechanical properties and tear resistance, and high puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] S1: Take 3g of titanium dioxide, 2g of dolomite powder and 10g of silica sol, put them into a reaction kettle, stir and react at a temperature of 60°C for 15min to obtain a mixture A; take 80g of high-density polyethylene, 15g of polyvinyl alcohol and 5g of 3-methoxy Phenol was put into the reaction kettle, stirred and reacted at a temperature of 120° C. for 1 hour, then the mixed solution A and 6 g of pentaerythritol were added, and stirred and reacted for 20 minutes to obtain the material for the outer layer;

[0027] S2: Add 11 g of toluenesulfonic acid aqueous solution to 2 g of plant fibers, reflux and stir for 3 h under a nitrogen atmosphere at a temperature of 90 ° C, then cool to room temperature, and filter by suction to obtain a precipitate; then add 7 g of 2-aminoterephthalic acid, in Reflux and stir at 100°C for 2 hours to obtain modified plant fibers;

[0028] S3: Mix 40 g of metallocene linear polyethylene, 10 g of acrylonitrile-butadiene-styrene and 5 g o...

Embodiment 2

[0032] S1: Take 5g of titanium dioxide, 6g of dolomite powder and 20g of silica sol, put them into a reaction kettle, stir and react at a temperature of 80°C for 30min to obtain a mixture A; take 100g of high-density polyethylene, 25g of polyvinyl alcohol and 10g of 3-methoxy Put phenol into the reaction kettle, stir and react at a temperature of 150° C. for 3 hours, then add the mixed solution A and 15 g of pentaerythritol, and continue to stir and react for 40 minutes to obtain the material for the outer layer;

[0033] S2: Add 11 g of toluenesulfonic acid aqueous solution to 2 g of plant fibers, reflux and stir for 6 h under a nitrogen atmosphere at a temperature of 130 ° C, then cool to room temperature, and filter by suction to obtain a precipitate; then add 7 g of 2-aminoterephthalic acid, in Reflux and stir at 140°C for 5 hours to obtain modified plant fibers;

[0034] S3: Mix 70 g of metallocene linear polyethylene, 20 g of acrylonitrile-butadiene-styrene and 10 g of t...

Embodiment 3

[0038] S1: Take 4g of titanium dioxide, 5g of dolomite powder and 15g of silica sol, put them into a reaction kettle, stir and react at a temperature of 75°C for 25min to obtain a mixture A; take 95g of high-density polyethylene, 20g of polyvinyl alcohol and 7g of 3-methoxy Put phenol into the reaction kettle, stir and react at a temperature of 140° C. for 2.5 hours, then add the mixed solution A and 10 g of pentaerythritol, and continue to stir and react for 30 minutes to obtain the material for the outer layer;

[0039] S2: Add 11 g of toluenesulfonic acid aqueous solution to 2 g of plant fibers, reflux and stir for 4.5 h under a nitrogen atmosphere at a temperature of 110 ° C, then cool to room temperature, and suction filter to obtain a precipitate; then add 7 g of 2-aminoterephthalic acid, Reflux and stir for 3 hours at a temperature of 120°C to obtain modified plant fibers;

[0040] S3: Mix 60 g of metallocene linear polyethylene, 15 g of acrylonitrile-butadiene-styrene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com