High-performance polylactic acid-based thermoplastic material as well as preparation method and application thereof

A thermoplastic material, polylactic acid-based technology, applied in the field of high-performance polylactic acid-based thermoplastic materials and their preparation, can solve the problems of high brittleness, poor temperature resistance and difficulty of polylactic acid, and achieve enhanced toughness and thermal stability, high temperature resistance Good performance and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

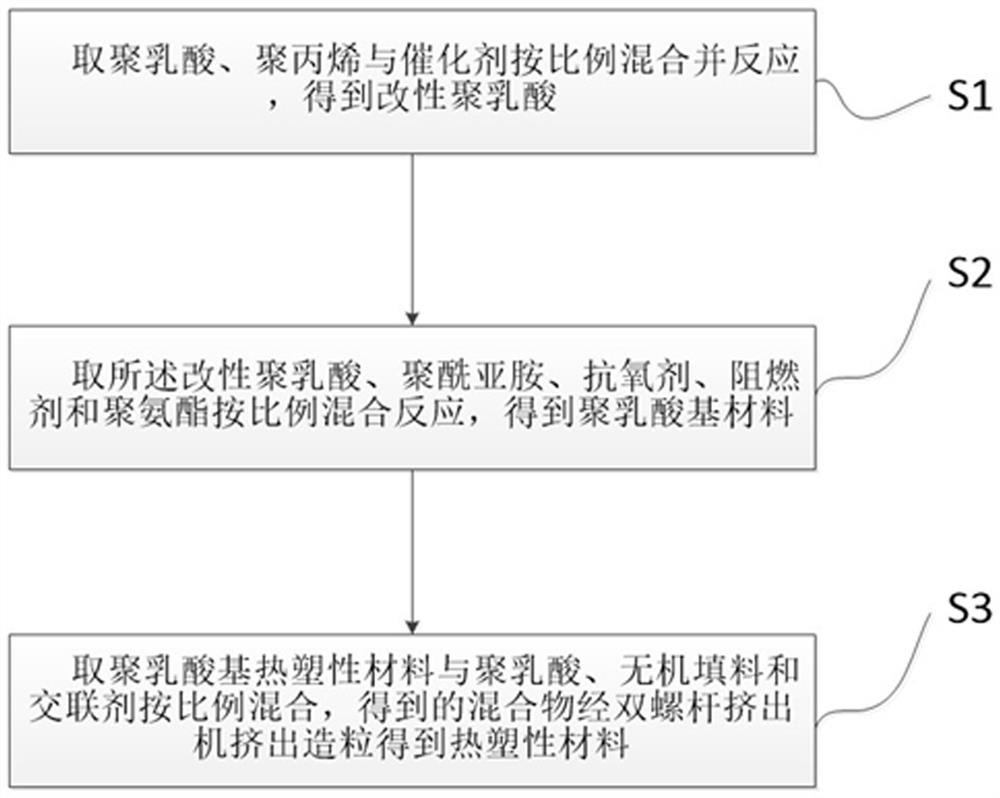

[0044] A kind of preparation method of high-performance polylactic acid base thermoplastic material, such as figure 1 As shown, the method includes the following steps:

[0045]S1. Mix polylactic acid, polypropylene and catalyst in proportion and react to obtain modified polylactic acid;

[0046] S2. The crystallinity of modified polylactic acid can reach 40%, and the heat distortion temperature can be increased to above 110;

[0047] S3. Mix and react the modified polylactic acid, polyimide, antioxidant, flame retardant and polyurethane in proportion to obtain a polylactic acid-based material;

[0048] In the examples of the present application, the toughness of polylactic acid is greatly improved by modifying polylactic acid. Because polylactic acid is a semi-crystalline polyester, the glass transition temperature is high, although it has a certain hardness, but the toughness is poor; while the polymer synthesized with polypropylene and polyurethane has a lower glass trans...

Embodiment 1

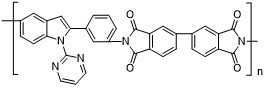

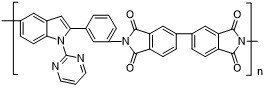

[0053] This implementation regulation discloses a high-performance polylactic acid-based thermoplastic material. The components of the thermoplastic material include 50 parts of polylactic acid, 5 parts of polypropylene, 0.5 parts of catalyst, 5 parts of polyimide, 0.1 part of antioxidant, 2 parts Part polyurethane, 0.5 part inorganic filler, 0.1 part flame retardant and 0.5 part crosslinking agent. The molar ratio of alumina and titania in the catalyst is 1:1. The polyimide is a polyimide containing an asymmetric indole structure, wherein the general chemical formula is:

[0054]

[0055] N is 6.

[0056] A preparation method of polylactic acid-based thermoplastic polyurethane, comprising the steps of:

[0057] Take polylactic acid, polypropylene and catalyst in proportion and mix them evenly in the reactor, heat the reactor to 130-180°C and react for 1-6 hours to obtain modified polylactic acid;

[0058] Take the modified polylactic acid, polyimide, antioxidant, flame ...

Embodiment 2

[0061] This embodiment discloses a high-performance polylactic acid-based thermoplastic material. The components of the thermoplastic material include 100 parts of polylactic acid, 25 parts of polypropylene, 6 catalysts, 25 parts of polyimide, 0.5 parts of antioxidant, 10 Parts of polyurethane, 6 parts of inorganic filler, 20 parts of flame retardant and 3 parts of crosslinking agent. The molar ratio of alumina and titania in the catalyst is 1:1.

[0062] A preparation method of polylactic acid-based thermoplastic polyurethane, comprising the steps of:

[0063] Take polylactic acid, polypropylene and catalyst in proportion and mix them evenly in the reactor, heat the reactor to 130-180°C and react for 1-6 hours to obtain modified polylactic acid;

[0064] Take the modified polylactic acid, polyimide, antioxidant, flame retardant and polyurethane and mix them uniformly in the reactor according to the proportion. The reactor is heated to 180-220°C and reacted for 3-6 hours to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com