Device and method for preparing fuel gas through gasification of biomass horizontal gasification furnace

A technology of horizontal gasifier and biomass fuel, which is applied in the direction of horizontal gasifier, combustible gas production, gasification process, etc. It can solve the problem of affecting the economic value of charcoal, poor sealing effect of feeding system, and affecting gas transportation and use problems, to achieve the effect of improving economic utilization value, good sealing, improving calorific value and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

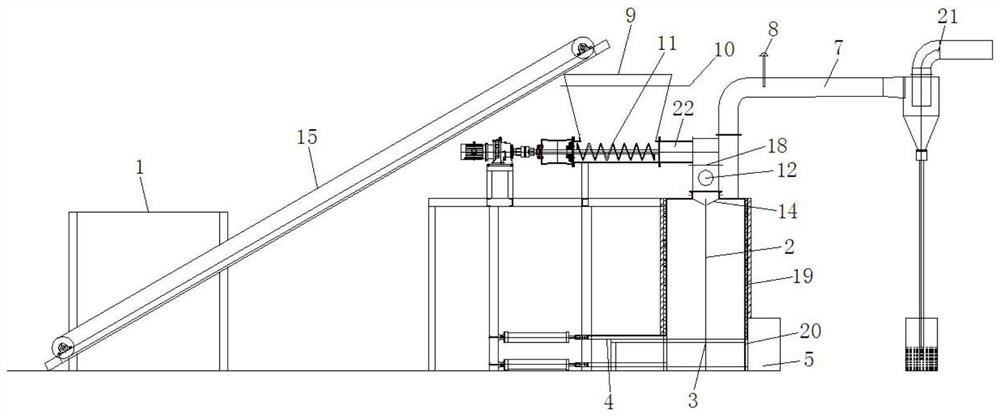

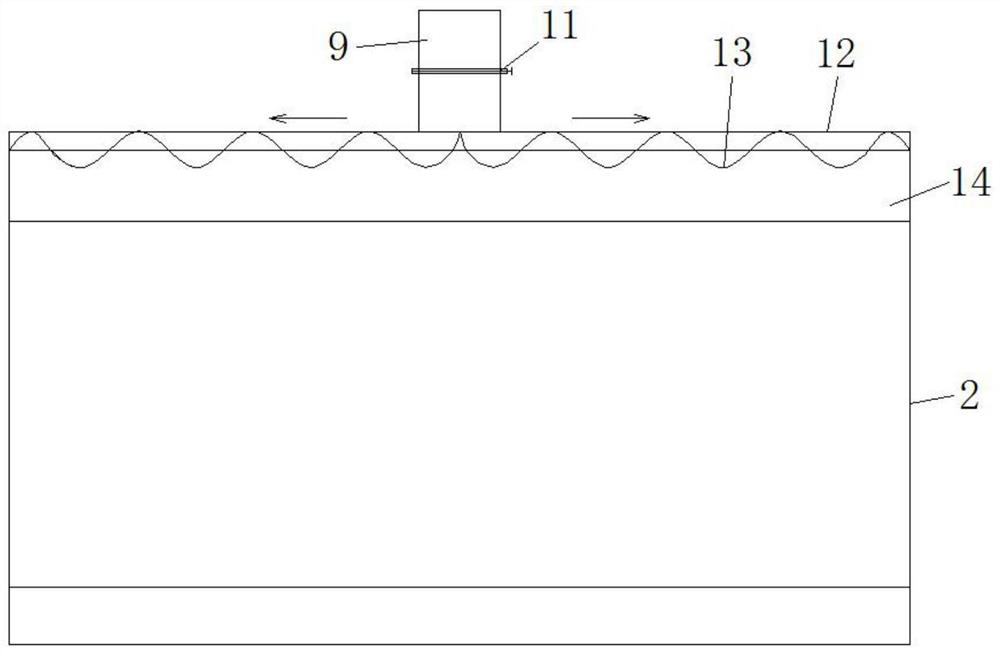

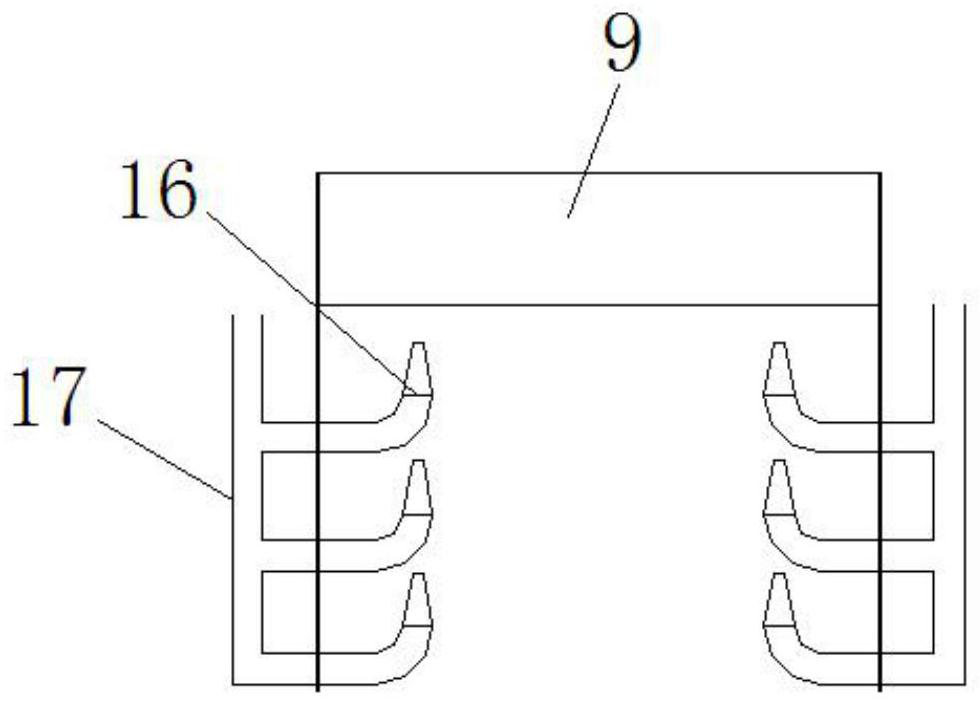

[0032] see Figure 1-Figure 4 , the present invention provides a biomass horizontal gasifier gasification gas production device, including: feeding system, horizontal furnace body, cooling and heat recovery system, charcoal output system, gas transmission and purification system, controller , wherein, the feeding system includes: a first-level distribution bin 1, a second-level distribution bin 9, a distribution device 12, a belt conveyor 15, a cooling system includes: an air-cooled jacket 19, a water-cooled jacket 20, and the charcoal output system includes: Two-stage charcoal pushing device 4 , scraper machine 5 , slag cooler 5 , gas delivery and purification system includes: gas delivery pipeline 7 , cyclone dust collector 21 .

[0033] In the actual working p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com