Mixed carbon source induced pichia pastoris expression recombinant batroxobin and purification method thereof

A Pichia pastoris and mixed carbon source technology, which is applied in the field of efficient production of medicinal enzyme proteins, can solve problems such as difficult removal, confusion of different types of snake venom, and difficulty in quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

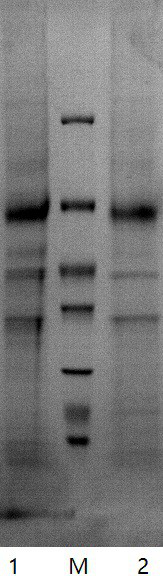

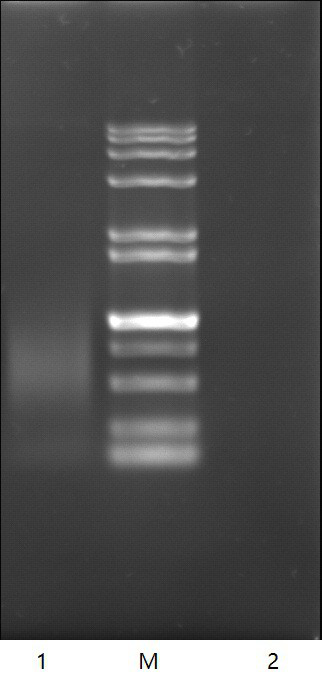

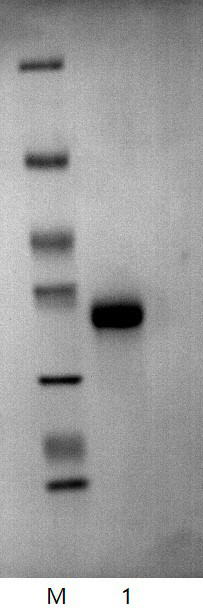

Image

Examples

Embodiment 1

[0042] Inoculate 1 ml of frozen working seeds of Pichia batroxobin and Pichia engineered bacteria into a 500 ml Erlenmeyer flask containing 100 ml of YPD medium. Under the conditions of 30° C. and 220 rpm, aeration and shaking were carried out for 20 hr. Measure its OD the next day 600 The value is 12.4. Add 24ml YPD medium to dilute and mix well. Take 10ml of the diluted first-class species and inoculate it into 500ml Erlenmeyer flasks containing 100ml of YPD medium, a total of 10 flasks. 30° C., 220 rpm, shake culture for 5 hours, and then inoculate the fermenter as fermentation seeds.

[0043] Prepare 20 liters of FM22 medium, and adjust the pH of the prepared basal salt medium to 4.5 with KOH. Divide into four 10-liter fermenters in 5-liter portions and autoclave. Sterilization conditions: 121°C, 20min. After sterilization, cool down to 30°C and add 10ml of PTM4 to each can. Ammonia water adjusts the pH value of the fermentation medium to 4.5. Maintain a stirring r...

Embodiment 2

[0051] Inoculate 1 ml of frozen working seeds of Pichia batroxobin and Pichia engineered bacteria into a 500 ml Erlenmeyer flask containing 100 ml of YPD medium. Under the conditions of 30° C. and 220 rpm, aeration and shaking were carried out for 20 hr. Measure its OD the next day 600 The value is 13.1. Add 31ml YPD medium to dilute and mix well. Take 10ml of the diluted first-class species and inoculate it into 500ml Erlenmeyer flasks containing 100ml of YPD medium, a total of 10 flasks. 30° C., 220 rpm, shake culture for 5 hours, and then inoculate the fermenter as fermentation seeds.

[0052] Prepare 20 liters of FM22 medium, and adjust the pH of the prepared basal salt medium to 4.5 with KOH. Divide into four 10-liter fermenters in 5-liter portions and autoclave. Sterilization conditions: 121°C, 20min. After sterilization, cool down to 30°C and add 10ml of PTM4 to each can. Ammonia water adjusts the pH value of the fermentation medium to 4.5. Maintain a stirring r...

Embodiment 3

[0060] Inoculate 1 ml of frozen working seeds of Pichia batroxobin and Pichia engineered bacteria into a 500 ml Erlenmeyer flask containing 100 ml of YPD medium. Under the conditions of 30° C. and 220 rpm, aeration and shaking were carried out for 20 hr. Measure its OD the next day 600 The value is 13.5. Add 35ml YPD medium to dilute and mix well. Take 10ml of the diluted first-class species and inoculate it into 500ml Erlenmeyer flasks containing 100ml of YPD medium, a total of 10 flasks. 30° C., 220 rpm, shake culture for 5 hours, and then inoculate the fermenter as fermentation seeds.

[0061] Prepare 20 liters of FM22 medium, and adjust the pH of the prepared basal salt medium to 4.5 with KOH. Divide into four 10-liter fermenters in 5-liter portions and autoclave. Sterilization conditions: 121°C, 20min. After sterilization, cool down to 30°C and add 10ml of PTM4 to each can. Ammonia water adjusts the pH value of the fermentation medium to 4.5. Maintain a stirring r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com