Electrocatalyst D-Mo2TiC2/Ni nanosheet as well as preparation method and application thereof

An electrocatalyst, nanosheet technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of high price of platinum and limited implementation of scarcity, and achieve excellent HER kinetics, strong catalytic activity and stability, low charge Effect of transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

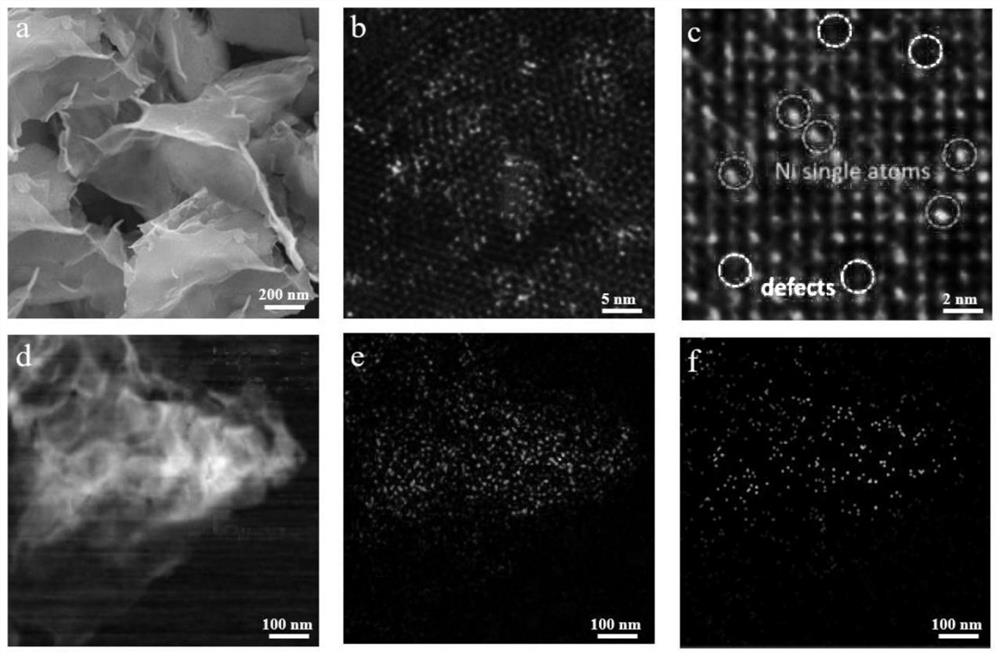

[0033] An electrocatalyst D-Mo 2 TiC 2 The preparation method of / Ni nano sheet, this method comprises:

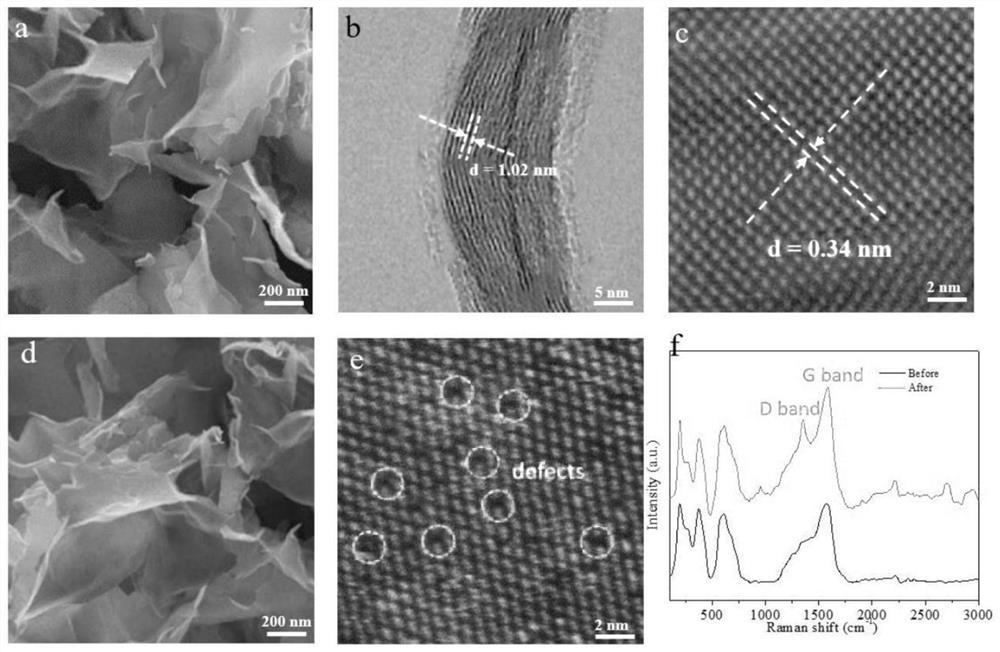

[0034] (1) Defect Mo 2 TiC 2 Synthesis of Nanosheets:

[0035] Mo 2 TiAlC 2 by mixing Mo (0.2 mol), Ti (0.1 mol), Al (0.11 mol) and C (graphite, 0.2 mol) in a glove box and internal grinding for 30 min. Then, the mixture was sealed in a quartz tube in an Ar environment and heated at 1600 °C for 4 h in a tube furnace. Afterwards, the annealed product was ground with a mortar / pestle to obtain Mo 2 TiAlC 2 .

[0036] Mo 2 TiC 2 Nanosheets chemically etched Mo 2 TiAlC 2 Synthesis, as follows:

[0037] Under magnetic stirring, the Mo 2 TiAlC 2 The powder (0.5 g) was added to a solution of HCl (50 mL, 9 mol / L) containing LiF (5 g). The suspension was transferred to a mechanically equipped autoclave (one atmosphere) and stirred at 60°C for 10 days. Finally, the product was washed 5 times with deionized water to obtain Mo 2 TiC 2 Nanosheets.

[0038] Defect Mo ...

experiment example 1

[0047] Experimental Example 1 Electrochemical Test

[0048] Electrochemical tests were performed on an electrochemical workstation (CHI 600E, CH Instrument) with a three-electrode system (counter electrode: graphite rod; reference electrode: SCE, saturated calomel electrode; working electrode).

[0049] The working electrode was carbon paper with catalyst slurry coating. Wherein, the catalyst slurry was obtained by mixing the catalyst (2 mg), Nafion (80 μL, 6 wt %) and ethanol (1 mL) and sonicating for 1 h. Drop 0.25mL of catalyst slurry on carbon paper (0.7cm x 0.7cm), the amount of catalyst is about 1mg / cm 2 , and then evaporate the ethanol in a vacuum chamber at room temperature. Pt / C (40%) catalyst powders are commercially available.

[0050] Polarization curves were obtained at a scan rate of 5 mV / s and pH=2. To determine the electrochemical capacitance, CV measurements were performed at the open circuit potential at scan rates ranging from 10 to 1000 mV / s. The EIS s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com