Biological protein feed prepared from waste vinasse of Jimo rice wine and preparation method of biological protein feed

A biological protein feed and biological protein technology, applied in the field of microbial fermentation engineering, can solve the problems of amino acid imbalance, cost reduction, poor palatability, etc., and achieve the effects of enhancing disease resistance, increasing income, and improving palatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Example 1 Jimo old distiller's grains fermentation strain screening

[0085] Take fresh old Jimo distiller's grains (discarded grains), and pack them into 250ml triangular bottles, each containing 100g.

[0086] Prepare 1000ml of PDA (potato sucrose) culture medium, and pack into 250ml Erlenmeyer flasks, each containing 50ml. After bandaging, steam sterilize at 120°C for 20 minutes, and cool down for later use.

[0087] Prepare 1000ml of beef extract peptone medium, pack in 250ml triangular flasks, and fill each bottle with 50ml. After bandaging, steam sterilize at 120°C for 20 minutes, and cool down for later use.

[0088] Pick 1 ring from the slopes of different preserved strains and insert them into the above culture medium. Fungi were inoculated into PDA medium and cultured in shake flasks at 30°C for 3 days; bacteria were inoculated into beef extract peptone medium and cultured in shake flasks at 33°C for 2 days. as a seed culture medium.

[0089] As shown in ...

Embodiment 2

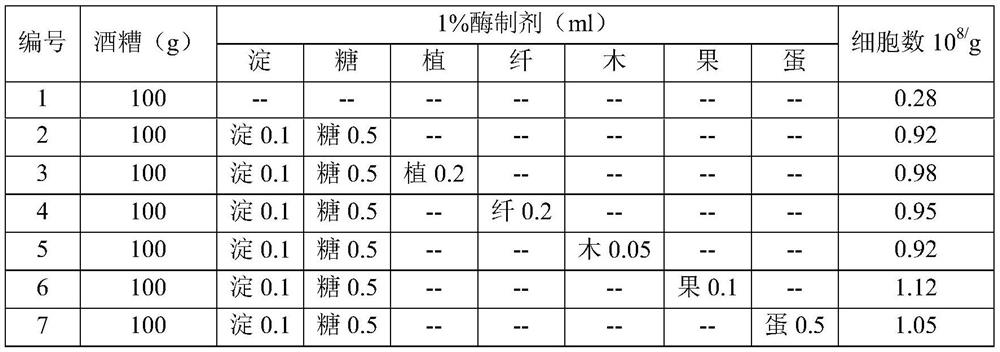

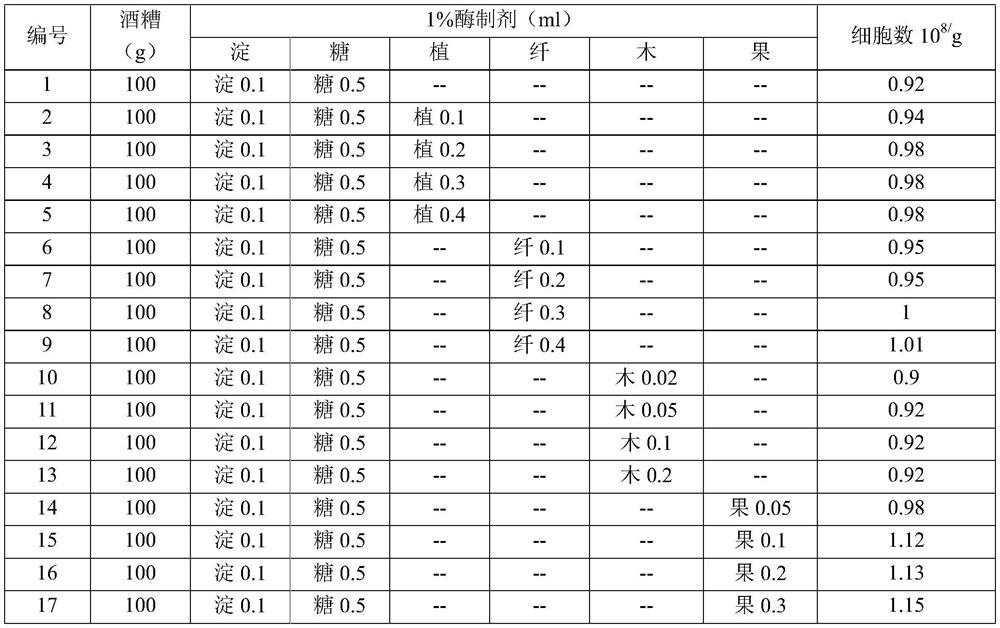

[0102] Example 2 The test of adding enzyme preparation in the fermentation of Jimo old distiller's grains

[0103] Weigh 1 g of 10,000 U / g amylase, add 100 ml of water, and prepare a 1% solution. Weigh 1 g of 100,000 U / g glucoamylase, add 100 ml of water, and prepare a 1% solution. Weigh 1 g of 10,000 U / g phytase, add 100 ml of water, and prepare a 1% solution. Weigh 1 g of 10,000 U / g cellulase, add 100 ml of water, and prepare a 1% solution. Weigh 1 g of 200,000 U / g xylanase, add 100 ml of water, and prepare a 1% solution. Weigh 1 g of 20,000 U / g pectinase, add 100 ml of water, and prepare a 1% solution. Weigh 1 g of 50,000 U / g neutral protease, add 100 ml of water, and prepare a 1% solution.

[0104] According to the method of Example 1, the PDA (potato sucrose) medium was prepared, and the seed culture liquids of Candida utilis and Kluyveromyces marxense were prepared respectively. Then take 20ml of culture solution and mix them at 1:1 to become the seed culture soluti...

Embodiment 3

[0116] Example 3 Experiment of strain ratio and addition amount in fermentation of Jimo old distiller's grains

[0117] Weigh 7 kinds of enzyme preparations according to weight ratio: 0.2 parts of amylase, 1 part of glucoamylase, 0.4 parts of phytase, 0.6 parts of cellulase, 0.1 part of xylanase, 0.4 parts of pectinase, 1 part of neutral protease parts, mixed evenly, a total of 3.7 parts. Then weigh 10 g, add 100 ml of water, and make 10% mixed enzyme solution.

[0118] According to the method of Example 1, the PDA medium was prepared, and the seed culture liquids of Candida utilis and Kluyveromyces marxense were prepared respectively.

[0119] Take fresh old Jimo distiller's grains (discarded grains), and pack them into 500ml triangular bottles, each containing 200g. See Table 6 below to inoculate seed culture solutions of different yeasts and add enzyme preparations respectively. Incubate at 30°C for 3 days. Determination of cell number and determination of acid soluble pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com