Hydroxyapatite and preparation method thereof

A technology of hydroxyapatite and biogas residue, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high cost of raw materials, easy product agglomeration, and large consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0064] Parallel example 1:

[0065] 1) Take every 1kg of biogas residue and add 1L of water, stir evenly, put it into a hydrothermal kettle, keep it warm at 160°C for 6 hours, after cooling, filter it with a 200-mesh filter sieve, and set it in a drying oven at 60°C to dry. After drying, the first product was obtained and set aside.

[0066] 2) The first product obtained after drying is placed in a calciner for calcination, the calcination temperature is set at 700° C., and the calcination treatment time is 2 hours, then the second product is obtained.

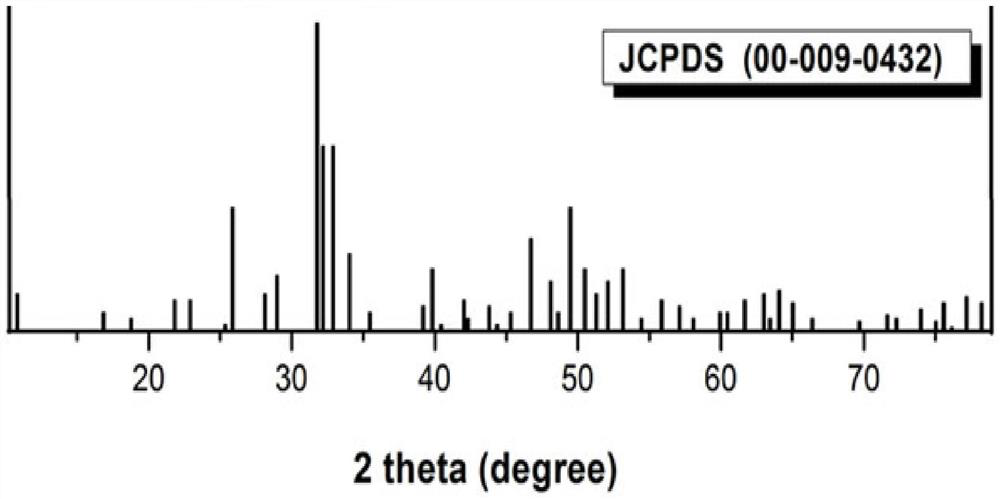

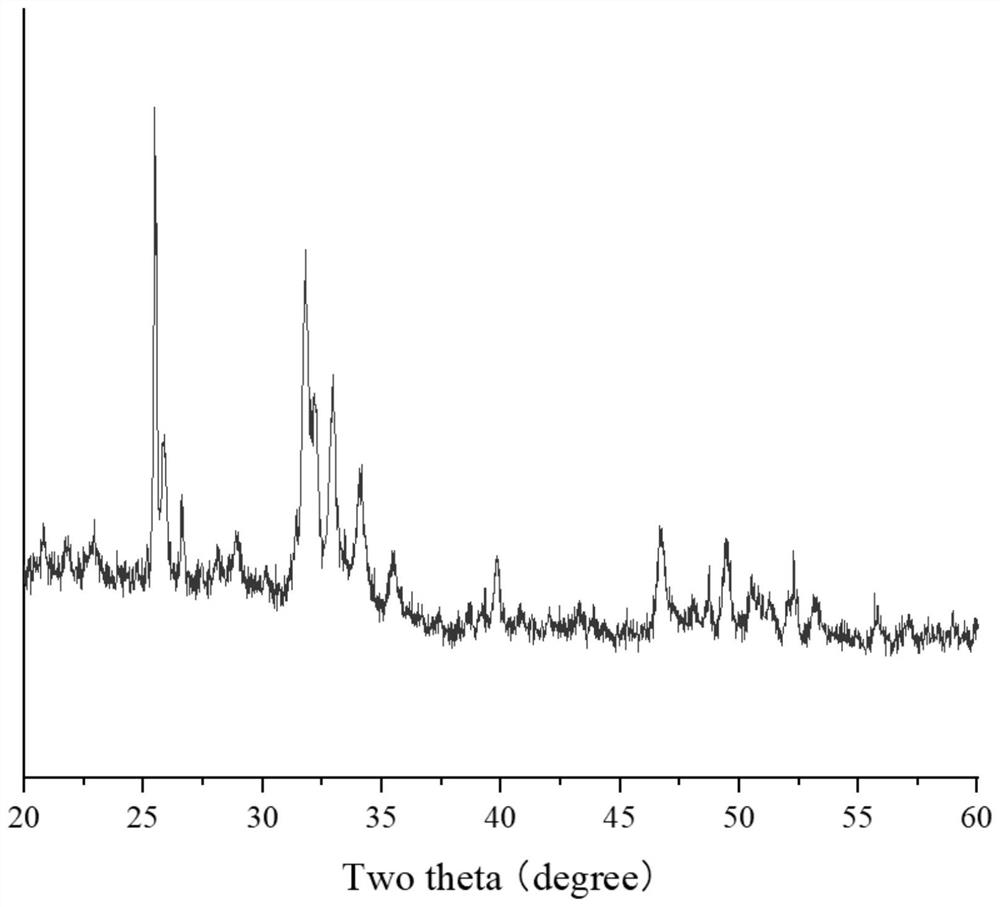

[0067] 3) Perform an X-ray diffraction test on the second product obtained in Parallel Example 1, and compare its characteristic peaks with those of hydroxyapatite, so as to determine whether the second product is hydroxyapatite.

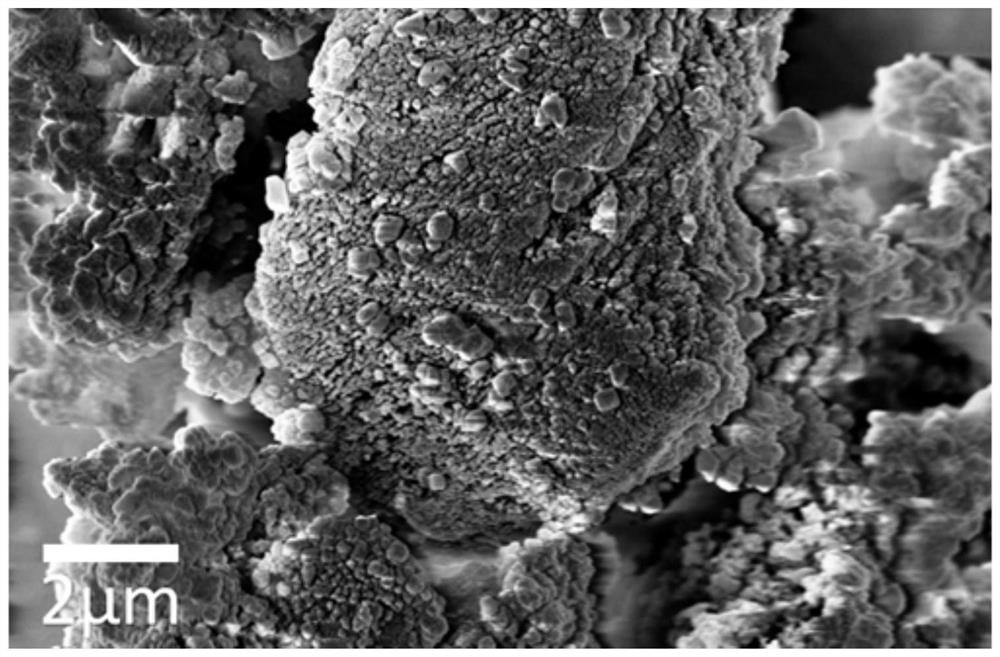

[0068] 4) Using an electronic scale, the mass of the second product obtained in Parallel Example 1 was taken as 18 g, and a field emission scanning electron microscope was used to scan the image of...

Embodiment 1

[0079] 1) Add 3L of water to every 1kg of biogas residue, stir it evenly, put it into a hydrothermal kettle, keep it warm at 170°C for 6 hours, and after cooling, filter it with a 200-mesh filter sieve, and set it in a drying oven at 60°C for drying. After drying, the first product was obtained and set aside.

[0080] 2) The first product obtained after drying is placed in a calciner for calcination, the calcination temperature is set at 700° C., and the calcination treatment time is 2 hours, then the second product is obtained.

[0081] 3) Carry out an X-ray diffraction test on the second product calcined in Example 1, and compare its characteristic peaks with those of hydroxyapatite, so as to determine whether the second product is hydroxyapatite.

[0082] 4) By means of an electronic scale, the mass of the second product obtained in Example 1 is 18 g, and the images of each parallel example and example are scanned by a field emission scanning electron microscope.

[0083] ...

Embodiment 2

[0086] 1) Add 4.5L of water to every 1kg of biogas residue, stir evenly, put it into a hydrothermal kettle, keep it warm at 160°C for 6h, after cooling, filter it with a 200-mesh filter sieve, and dry it in a drying oven at 60°C. The first product is obtained after drying, and is set aside.

[0087] 2) The first product obtained after drying is placed in a calciner for calcination, the calcination temperature is set at 800° C., and the calcination treatment time is 2 hours, then the second product is obtained.

[0088] 3) Carry out an X-ray diffraction test on the second product calcined in Example 2, and compare its characteristic peaks with those of hydroxyapatite, so as to determine whether the second product is hydroxyapatite.

[0089] 4) By means of an electronic balance, the mass of the second product obtained in Example 2 is taken as 18 g, and a field emission scanning electron microscope is used to scan an image of the second product obtained in Example 2.

[0090] 5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com