Optimization control method for natural yeast breeding and fermentation process

A fermentation process and optimization control technology, which is applied in the field of natural yeast breeding and fermentation, can solve the problems of control, lack of heat resistance and cold resistance of natural yeast strains, and affect the intermittent and continuous expansion of natural yeast. Control heat resistance and cold resistance, avoid the effect of intermittent and continuous expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

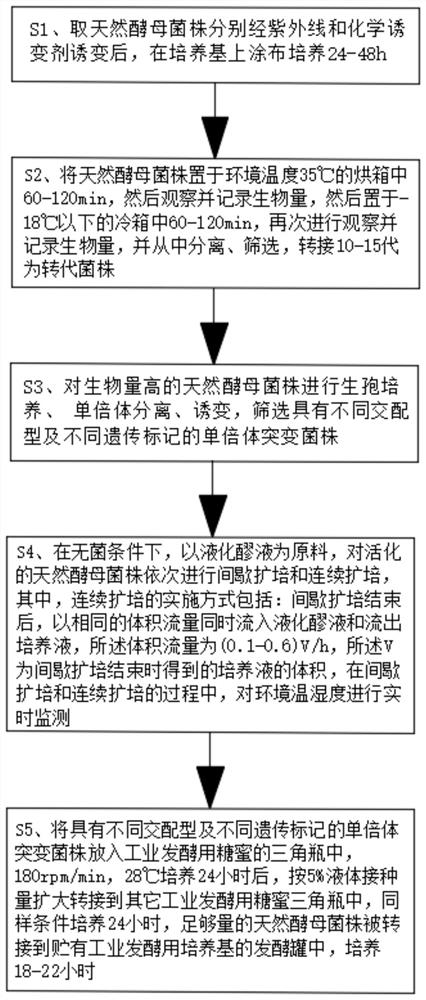

[0025] The present invention provides such figure 1 The optimization control method of the shown natural yeast breeding and fermentation process is characterized in that, comprises the following steps:

[0026] S1. After the natural yeast strains are mutagenized by ultraviolet rays and chemical mutagens, they are spread on the medium and cultured for 24-48 hours;

[0027] S2. Place the natural yeast strain in an oven at an ambient temperature of 35°C for 60-120min, then observe and record the biomass, then place it in a cold box below -18°C for 60-120min, observe again and record the biomass, and Isolate and screen from it, and transfer 10-15 generations to the transgenic strain;

[0028] In step S2, the freezing rate of natural yeast strains is controlled at -1°C / min, thawed at 28°C and 30 minutes after freezing for 8 hours, and the number of viable yeast before and after freezing is measured, and the strains with a freezing survival rate of 75%-90% are regarded as freeze-re...

Embodiment 2

[0050] On the basis of Example 1, in step S4, the culture conditions for continuous expansion are as follows: the temperature is 28-32°C, the ventilation rate is 0.08-0.2VVM, and the pH is 5-6; in step S4, the liquefied mash DE value of 50-80, the liquefied mash contains 0.2-1g / L potassium dihydrogen phosphate and 0.2-1g / L nitrogen source, the nitrogen source is one of urea, ammonia water and ammonium bicarbonate one or more species.

[0051] In step S4, the pipelines and valves through which the liquefied mash passes must be thoroughly sterilized with hot water or steam, and the air, ground, and walls in the expansion room must also be sterilized or sterilized, and the compressed air for oxygen supply needs to pass through 0.2pm membrane filtration, in step S5, the fermentor will pass oxygen 3 times during the fermentation process, each time passing oxygen for 5 minutes, and the industrial fermentation medium will also need to add urea 3-5g, diphosphate diphosphate in every 1...

Embodiment 3

[0053] On the basis of Example 1 and Example 2, the medium for industrial fermentation described in step S5 includes the organic matter of 8%-20% total sugar content, the zincate of 200-1000 micrograms / ml, the pH of the medium 3.5-8.5; the inoculum size of the fermentor culture is 5%-35%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com