Preparation method of spatially staggered mixed material film and application thereof in achromatic superlens

A technology of spatial interleaving and material thin film, applied in the direction of lens, metal material coating process, microscope, etc., can solve the problem of difficulty in realizing the interlaced local deposition of two semiconductor materials at the same time, and achieve the improvement of spot quality and achromatic performance, high The effect of transmittance and efficient focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The method for preparing an achromatic superlens based on multi-step deposition of spatially interlaced mixed material films provided by the present invention mainly includes the following steps:

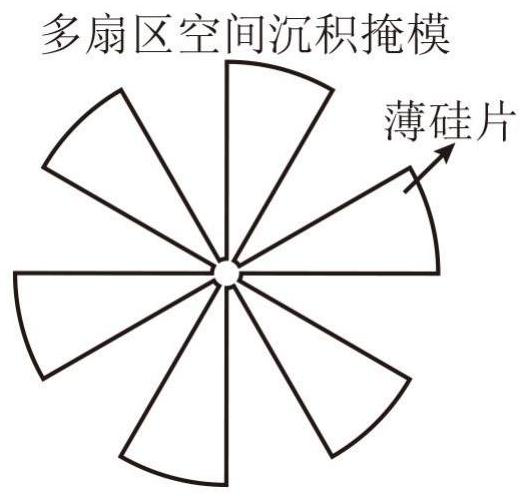

[0028] (1) Prepare a spatial deposition mask with a multi-sector structure: a thin silicon wafer with a thickness greater than the thickness of the thin film to be deposited (greater than 450 nm) is selected for the deposition mask. Under the microfabrication platform, using focused ion beam etching or femtosecond laser direct writing technology to process a multi-sector structure on a thin silicon wafer, its diameter is equivalent to the diameter of the expected metalens (between 40 μm and 100 μm). The spatial deposition mask is used for alternately covering subregions in the subsequent mixed material deposition process.

[0029] (2) Preparation of multi-step deposition of spatially interleaved mixed material films: first, the substrate is cleaned, and the substrate and mult...

Embodiment 1

[0037] Take the preparation of 920nm and 510nm dual-wavelength achromatic metalens and its application in two-photon fluorescence microscopy imaging as an example.

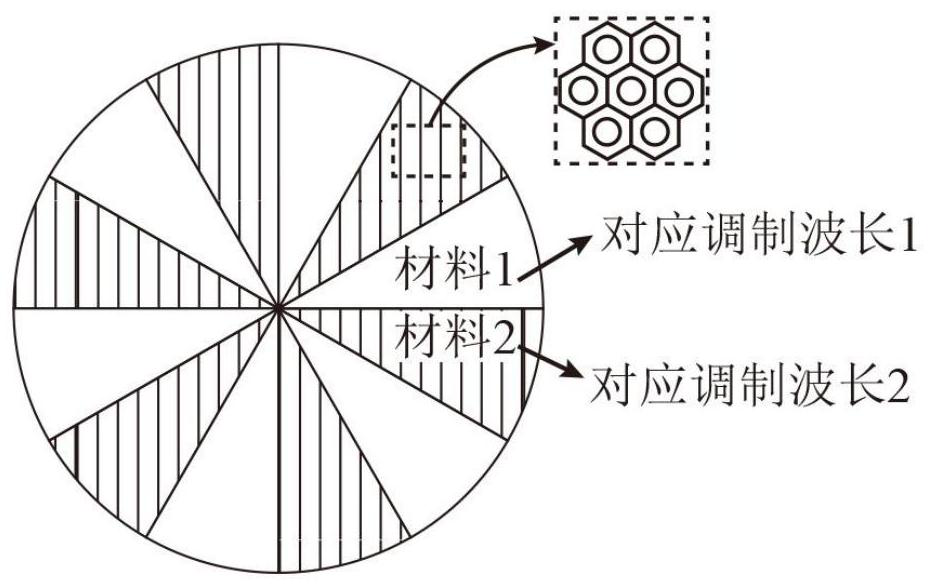

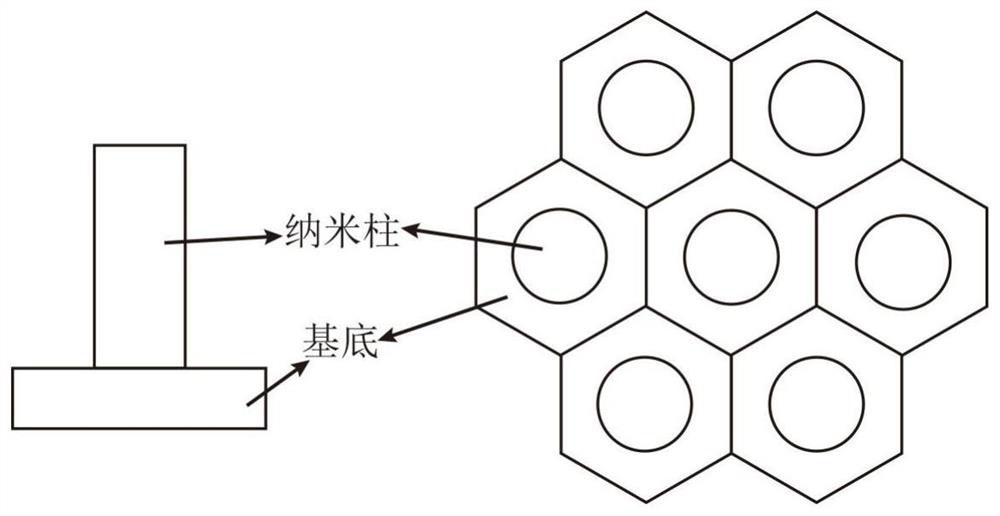

[0038] The planar structure diagram of the expected designed dual-wavelength achromatic metalens can be found in figure 1 , the superlens is composed of several nanopillars arranged in a regular hexagonal lattice structure. For the structure diagram of the nanounits, see figure 2 . Using green fluorescent protein as a fluorescent probe for two-photon fluorescence microscopy imaging, the two-photon excitation wavelength is 920nm, and the fluorescence wavelength is 510nm. Utilize above-mentioned processing method, at first process out multi-sector thin silicon chip (see specification attached image 3 ); and then deposit a dual-material thin film with a spatially partitioned structure on the substrate, wherein the first material is amorphous silicon for modulating 920nm excitation light, and the second material s...

Embodiment 2

[0041] Take the preparation of 910nm and 650nm dual-wavelength achromatic metalens and its application in two-photon STED micro-endoscopy imaging as an example.

[0042] The planar structure diagram of the expected designed dual-wavelength achromatic metalens can be found in figure 1 , the superlens is composed of several nanopillars arranged in a regular hexagonal lattice structure. For the structure diagram of the nanounits, see figure 2 . The two-photon excitation wavelength is 910nm, the loss wavelength is 650nm, and the fluorescence wavelength is close to the loss wavelength. Utilize above-mentioned processing method, at first process out multi-sector thin silicon chip (see specification attached image 3 ); and then deposit a space-partitioned dual-material mixed film on the substrate, wherein the first material is amorphous silicon for modulating 910nm excitation light, and the second material is titanium dioxide for modulating 650nm loss light. For the processing f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com