Self-crosslinking polymer modified asphalt emulsion and preparation method thereof

A modified asphalt, cross-linked technology, applied in the direction of building structure, building components, building insulation materials, etc., can solve the problem of poor storage stability of modified asphalt emulsion, high requirements for crushing degree and emulsifier, and construction time Higher control requirements and other issues, to achieve the effect of low cost, good anti-rutting ability, and improved weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

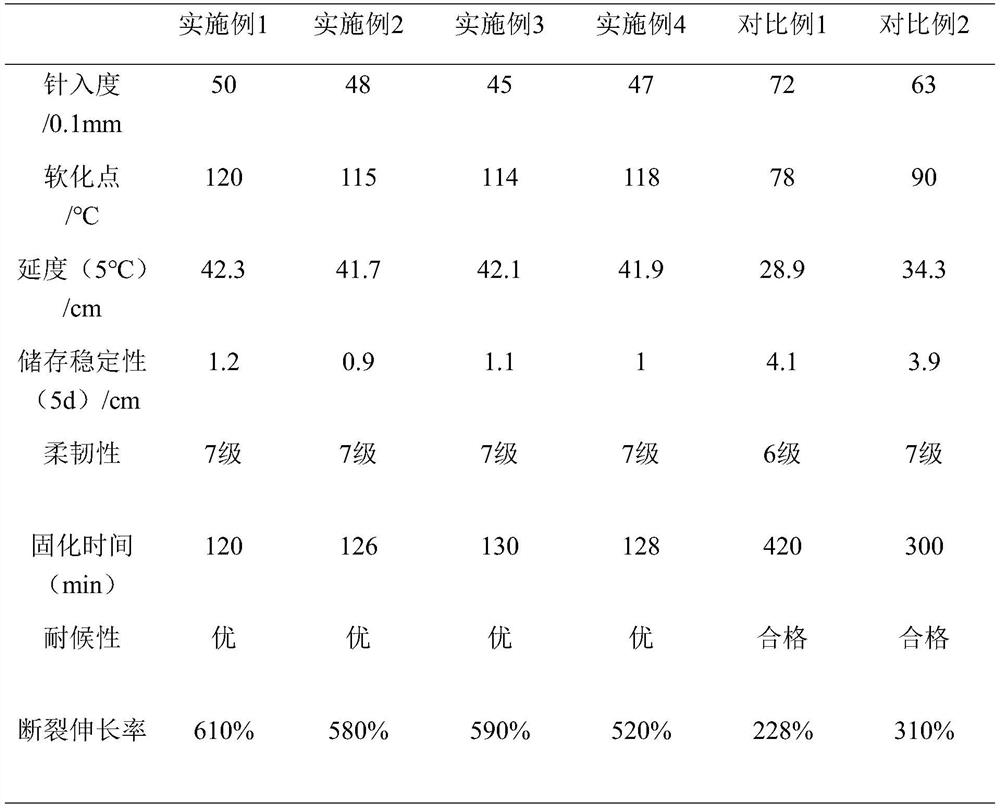

Examples

Embodiment 1

[0038] (1) Weigh 100 parts by weight of dicarboxyphenyl acetate monomer, 60 parts by weight of butadiene, 60 parts by weight of butyl methacrylate and 0.2 parts by weight of azobisisobutyronitrile and add them with stirring In the three-necked flask of the device and the condensing reflux device, heat and react with 800r / min speed stirring for 4 hours, then add 10 parts by weight of chlorosulfonic acid, and react for 1 hour. Finally, 5 parts by weight of 3% aqueous sodium hydroxide solution was added, stirred continuously for 1 hour, and dried to obtain a crosslinkable emulsification modifier.

[0039] (2) Weigh 10 parts by weight of cryptocrystalline graphene and 60 parts by weight of light coal tar and mix, then add 3 parts by weight of vinylsilane, and grind in a mill for 2 hours to obtain active cryptocrystalline graphene slurry. Weigh 50 parts by weight of matrix pitch, add 10 parts by weight of active cryptocrystalline graphene slurry and 20 parts by weight of cross-link...

Embodiment 2

[0042] (1) Weigh 100 parts by weight of dicarboxyphenyl acetate monomer, 70 parts by weight of butadiene, 50 parts by weight of butyl methacrylate and 10 parts by weight of azobisisobutyronitrile and add them with stirring In the three-necked flask of device and condensing reflux device, heating simultaneously with 1000r / min speed stirring reaction 4 hours, then add 13 parts by weight of chlorosulfonic acid, react 2 hours. Finally, 8 parts by weight of a 3% aqueous solution of sodium hydroxide was added, stirred continuously for 2 hours, and dried to obtain a crosslinkable emulsification modifier.

[0043] (2) Weigh 15 parts by weight of cryptocrystalline graphene and 45 parts by weight of light coal tar and mix, then add 5 parts by weight of vinylsilane, and grind in a mill for 1.5 hours to obtain active cryptocrystalline graphene slurry. Weigh 55 parts by weight of matrix pitch, add 15 parts by weight of active cryptocrystalline graphene slurry and 25 parts by weight of cros...

Embodiment 3

[0046] (1) Weigh 100 parts by weight of dicarboxyphenyl acetate monomer, 80 parts by weight of butadiene, 40 parts by weight of butyl methacrylate three kinds of reaction monomers and 20 parts by weight of dibenzoyl peroxide and add them with stirring In the three-necked flask of the device and the condensing reflux device, heat while stirring and reacting at a speed of 1000r / min for 4 hours, then add 11 parts by weight of chlorosulfonic acid, and react for 1 hour. Finally, 5 parts by weight of 3% aqueous sodium hydroxide solution was added, stirred continuously for 1 hour, and dried to obtain a crosslinkable emulsification modifier.

[0047] (2) Weigh 20 parts by weight of cryptocrystalline graphene and 30 parts by weight of light coal tar and mix, then add 8 parts by weight of vinylsilane, and grind in a mill for 2 hours to obtain active cryptocrystalline graphene slurry. Weigh 60 parts by weight of matrix pitch, add 20 parts by weight of active cryptocrystalline graphene sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com