Cu-high-entropy alloy thin film and preparation method thereof

A high-entropy alloy and thin-film technology, which is applied in metal material coating technology, ion implantation plating, coating, etc., can solve problems such as poor interface adhesion, increased resistance, and poor quality of pure copper oxides, and achieve thin-film Dense, well-bonded effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Present embodiment 1 is implemented under the following implementation conditions and technical requirements:

[0030] Firstly, the monocrystalline silicon substrate was ultrasonically cleaned for 10 minutes each in analytical pure acetone and ethanol, and then quickly dried with warm air.

[0031] Immediately fix it on the substrate, mechanically and automatically send it into the magnetron sputtering vacuum coating chamber, and pump it until the vacuum degree of the background is 3.0×10 -4 Pa.

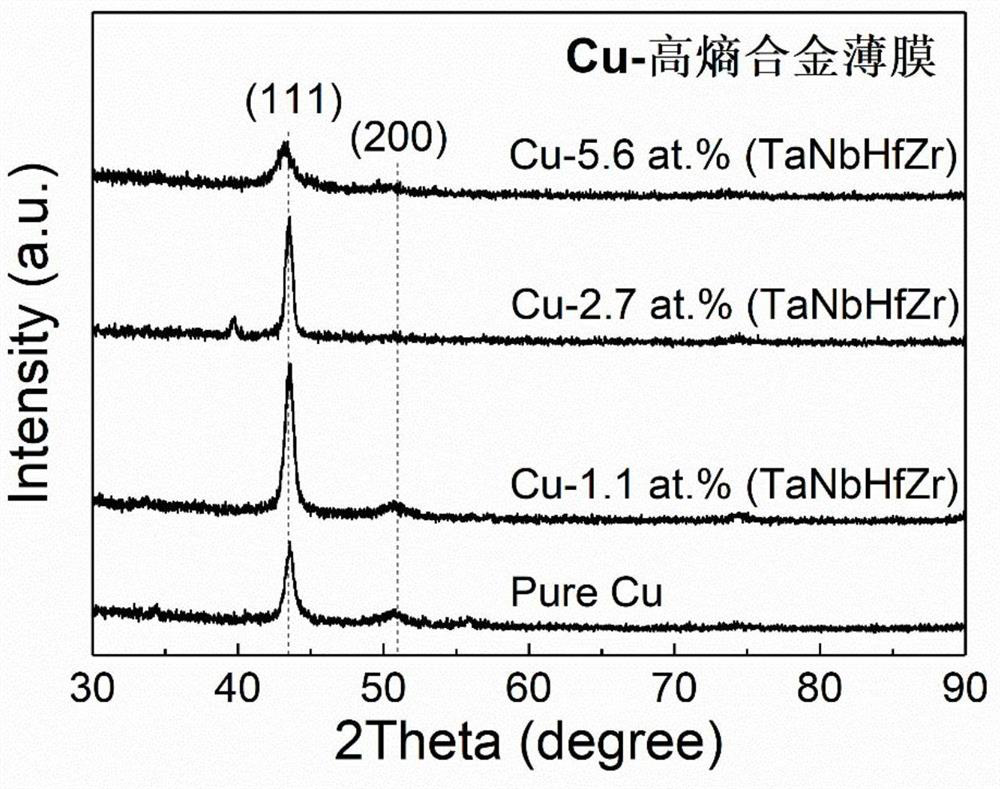

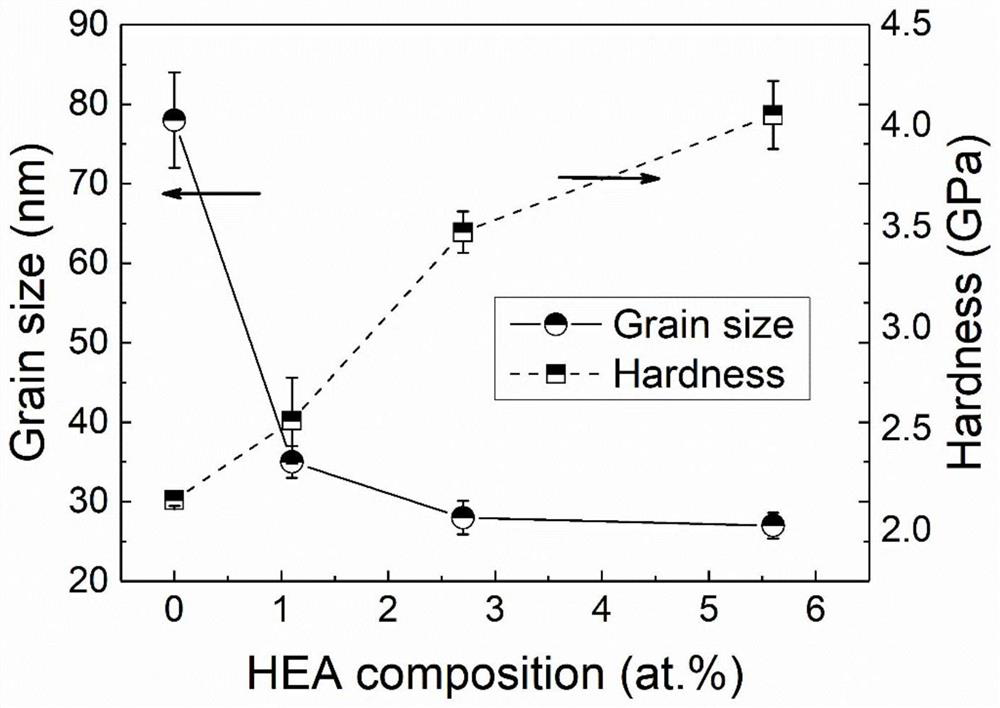

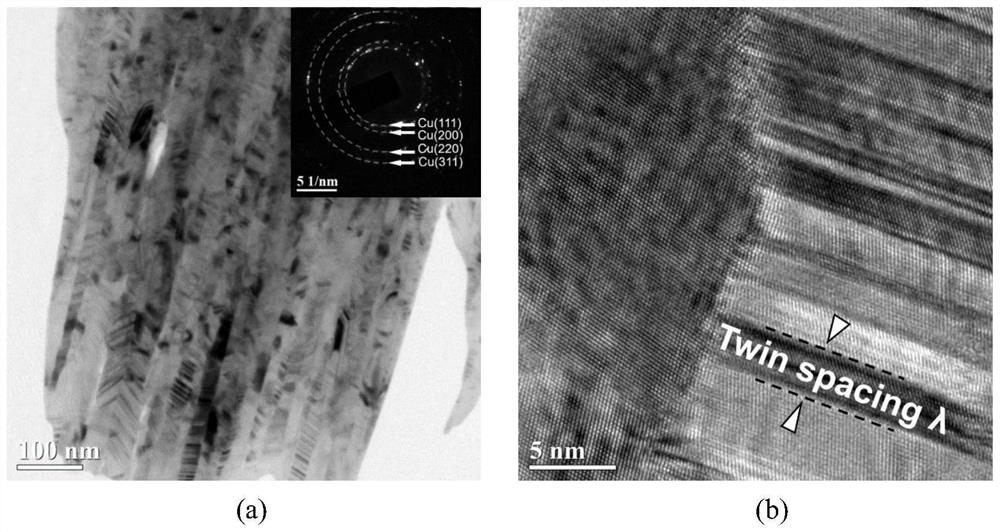

[0032] Then use magnetron sputtering dual DC power co-sputtering to deposit Cu-high entropy alloy thin film on the ultrasonically cleaned single crystal silicon wafer, wherein the Cu target purity is 99.99wt.%, using DC power supply, the power is 200W; high entropy TaNbHfZr The target purity is 99.95wt.%, and a DC power supply is used with a power of 20W. The deposition pressure was set at 0.3Pa, the deposition temperature was at room temperature, and the substrate rotation ...

Embodiment 2

[0036] This embodiment 2 is implemented under the following implementation conditions and technical requirements:

[0037] Firstly, the monocrystalline silicon substrate was ultrasonically cleaned for 10 minutes each in analytical pure acetone and ethanol, and then quickly dried with warm air.

[0038] Immediately fix it on the substrate, mechanically and automatically send it into the magnetron sputtering vacuum coating chamber, and pump it until the vacuum degree of the background is 3.0×10 -4 Pa.

[0039] Then use magnetron sputtering dual DC power co-sputtering to deposit Cu-high entropy alloy thin film on the ultrasonically cleaned single crystal silicon wafer, wherein the Cu target purity is 99.99wt.%, using DC power supply, the power is 200W; high entropy TaNbHfZr The target purity is 99.95wt.%, and a DC power supply is used with a power of 50W. The deposition pressure was set at 0.3Pa, the deposition temperature was at room temperature, and the substrate rotation spe...

Embodiment 3

[0043] This embodiment 3 is implemented under the following implementation conditions and technical requirements:

[0044] Firstly, the monocrystalline silicon substrate was ultrasonically cleaned for 10 minutes each in analytical pure acetone and ethanol, and then quickly dried with warm air.

[0045] Immediately fix it on the substrate, mechanically and automatically send it into the magnetron sputtering vacuum coating chamber, and pump it until the vacuum degree of the background is 3.0×10 -4 Pa.

[0046] Then use magnetron sputtering dual DC power co-sputtering to deposit Cu-high entropy alloy thin film on the ultrasonically cleaned single crystal silicon wafer, wherein the Cu target purity is 99.99wt.%, using DC power supply, the power is 200W; high entropy TaNbHfZr The target purity is 99.95wt.%, and a DC power supply is used with a power of 100W. The deposition pressure was set at 0.3Pa, the deposition temperature was at room temperature, and the substrate rotation sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com