Bimetal selenide negative electrode material and preparation method and application thereof

A negative electrode material, selenide technology, applied in the direction of negative electrode, active material electrode, battery electrode, etc., can solve the problems of limited battery cycle performance, difficulty in the decomposition of sodium oxide, poor stability of phosphide, etc., to achieve excellent electrochemical performance, Good application prospect and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing a double metal selenide negative electrode material of the present invention comprises the following steps:

[0045] S1, adding the first metal salt a, the second metal salt b, and the surfactant to the mixed solution of methanol and deionized water, the ratio of the addition amount of the first metal salt a to the second metal salt b is (0.5~ 2): 1. The volume ratio of methanol to deionized water is (0.2-5): 1. Stir to fully dissolve to obtain a wine-red solution;

[0046] Preferably, the first metal salt a is selected from nickel salts, and can be one or more of nitrates, chlorides, and sulfates; the second metal salt b is selected from cobalt salts, and can be nitrates, chlorides , One or more of sulfates.

[0047]Preferably, the surfactant is one or more of amine salt type, quaternary ammonium salt type, heterocyclic type and halo salt type.

[0048] Preferably, the added amount of the surfactant is 0.5-1 g.

[0049] S2. Transfer the wine-r...

Embodiment 1

[0055] (1) Weigh 1.8mmol nickel nitrate hexahydrate, 0.9mmol cobalt nitrate hexahydrate, 1g hexadecyltrimethylammonium bromide and dissolve in a mixed solution of 60mL ethanol and 15mL deionized water, stir for 30min to obtain a clear solution ;

[0056] Put the solution into a 100mL polytetrafluoroethylene-lined reactor, react at 180°C for 20h, cool naturally, centrifuge, wash, and vacuum-dry to obtain the precursor;

[0057] (2) The precursor and selenium powder were weighed according to the mass ratio of 1:2, poured into a mortar, manually ground for 30 minutes, and mixed evenly. Under an inert atmosphere, the mixture was annealed at 350° C. for 3 hours at a low temperature to obtain a double metal selenide.

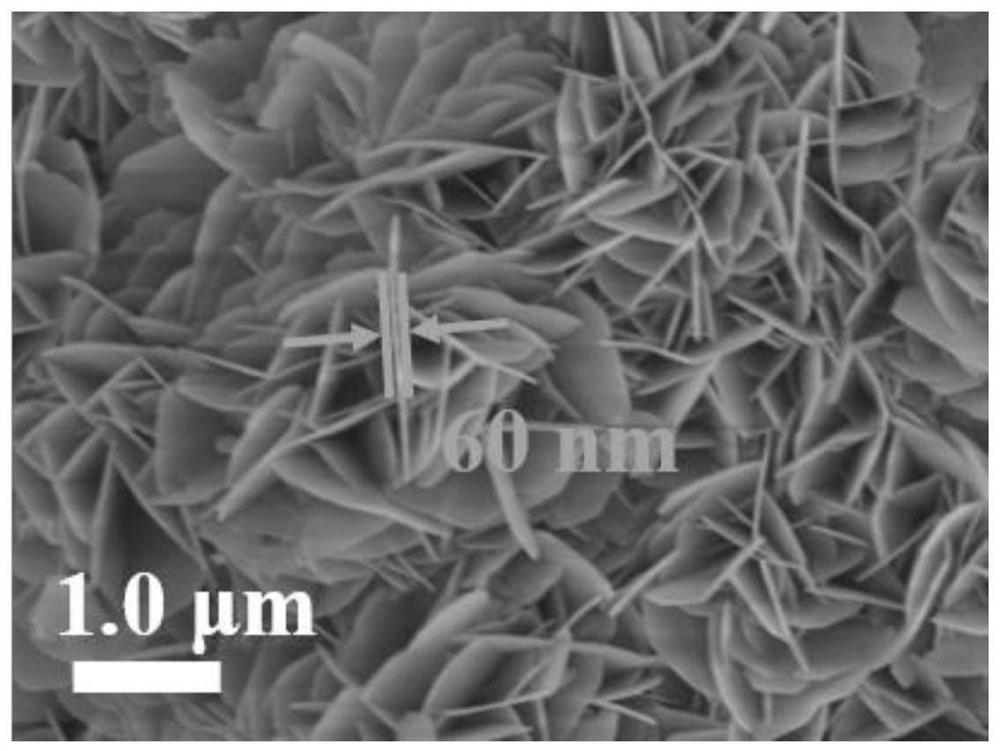

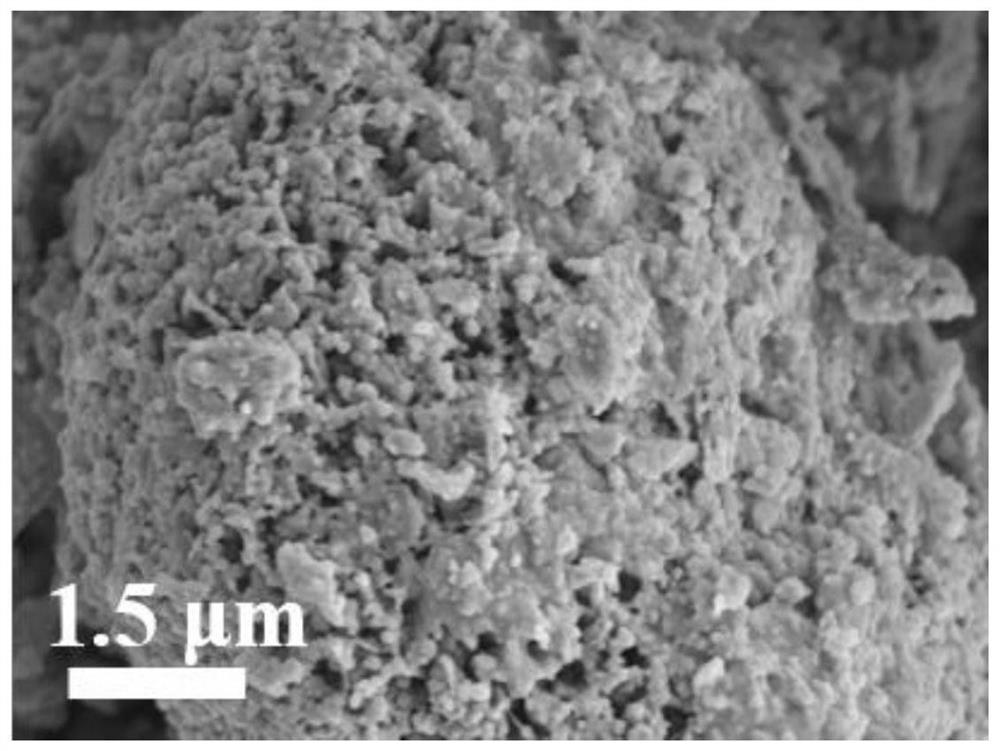

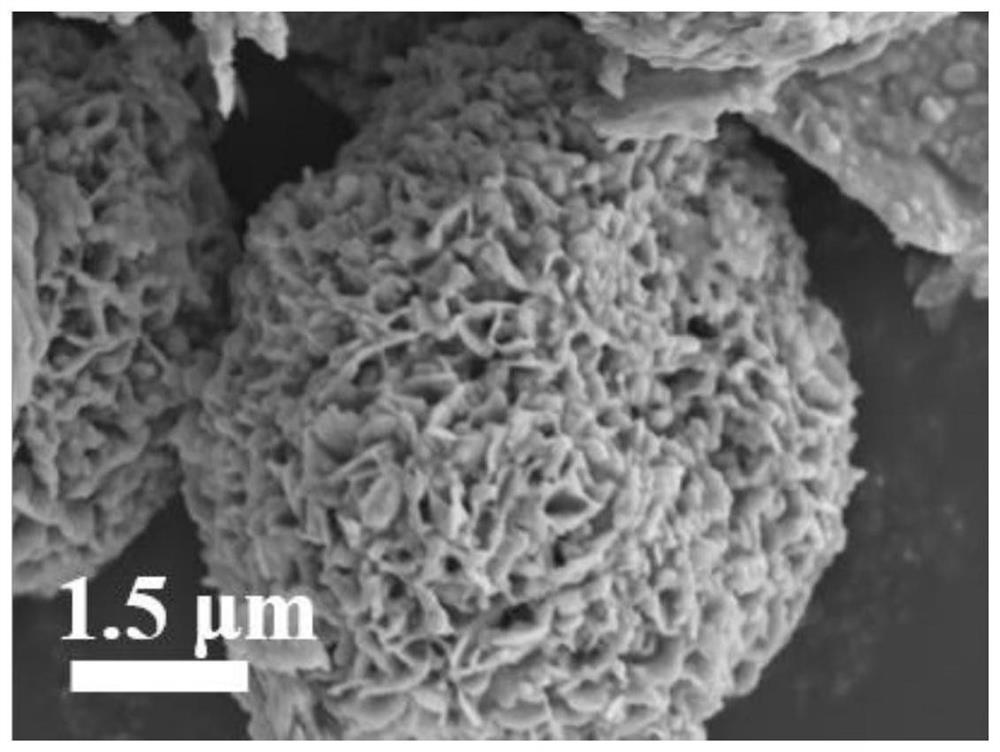

[0058] see figure 1 with figure 2 ,

Embodiment 2

[0060] (1) Dissolve 0.9mmol nickel nitrate hexahydrate, 1.8mmol cobalt nitrate hexahydrate, 1g octadecyldimethylbenzyl ammonium chloride in a mixed solution of 15mL ethanol and 60mL deionized water, and stir for 30min , to obtain a clear solution;

[0061] Put the solution into a 100mL polytetrafluoroethylene-lined reactor and react at 180°C for 20 hours; after natural cooling, centrifuge, wash, and vacuum-dry to obtain the precursor;

[0062] (2) The precursor and selenium powder were weighed according to the mass ratio of 1:2, poured into a mortar, manually ground for 30 minutes, and mixed evenly. Under an inert atmosphere, the mixture was annealed at a low temperature of 300° C. for 3 hours to obtain the above-mentioned double metal selenide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Reversible specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com