Ion exchange hybrid membrane for vanadium battery and preparation method thereof

A technology for ion exchange and vanadium batteries, applied in the field of ion exchange membranes, can solve the problems of limited number of functional functional groups, easy aggregation of silica particles, incompatibility and dispersion of polymers, etc., to achieve good chemical stability and improve The effect of proton transport density and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

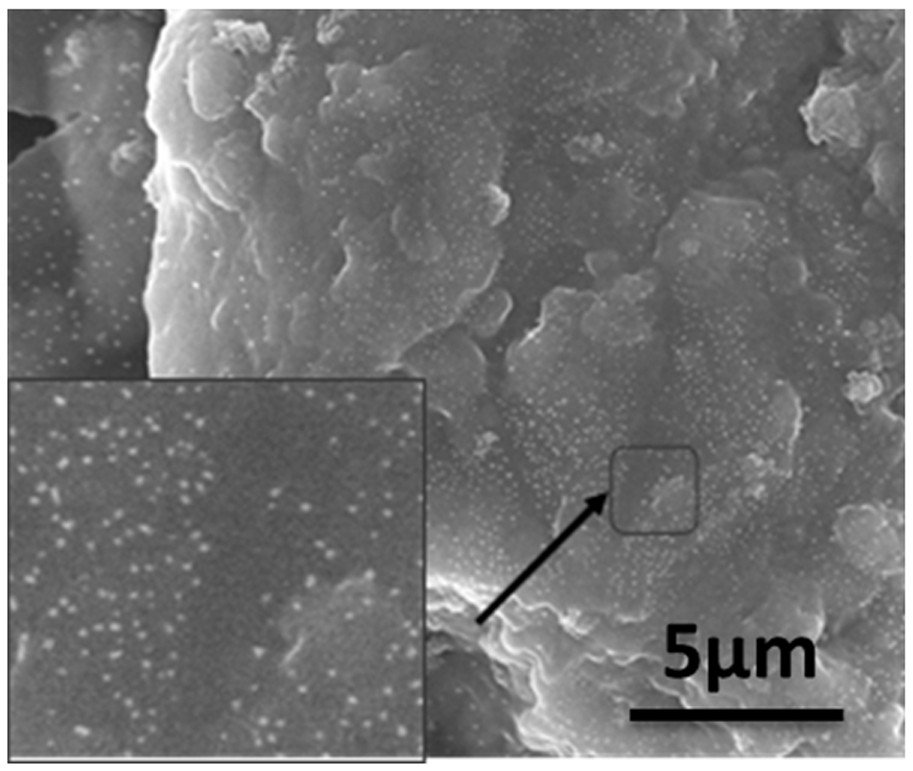

[0030] A method for preparing an ion-exchange hybrid membrane for a vanadium battery, comprising the following steps:

[0031] S1: Dry sulfonated polyether ether ketone with a sulfonation degree of 65% in a vacuum oven at 80°C for 6 hours to obtain pretreated sulfonated polyether ether ketone, and dissolve 10 g of pretreated sulfonated polyether ether ketone In 90g N,N-dimethylformamide, it is configured as a sulfonated polyether ether ketone solution with a mass concentration of 10%;

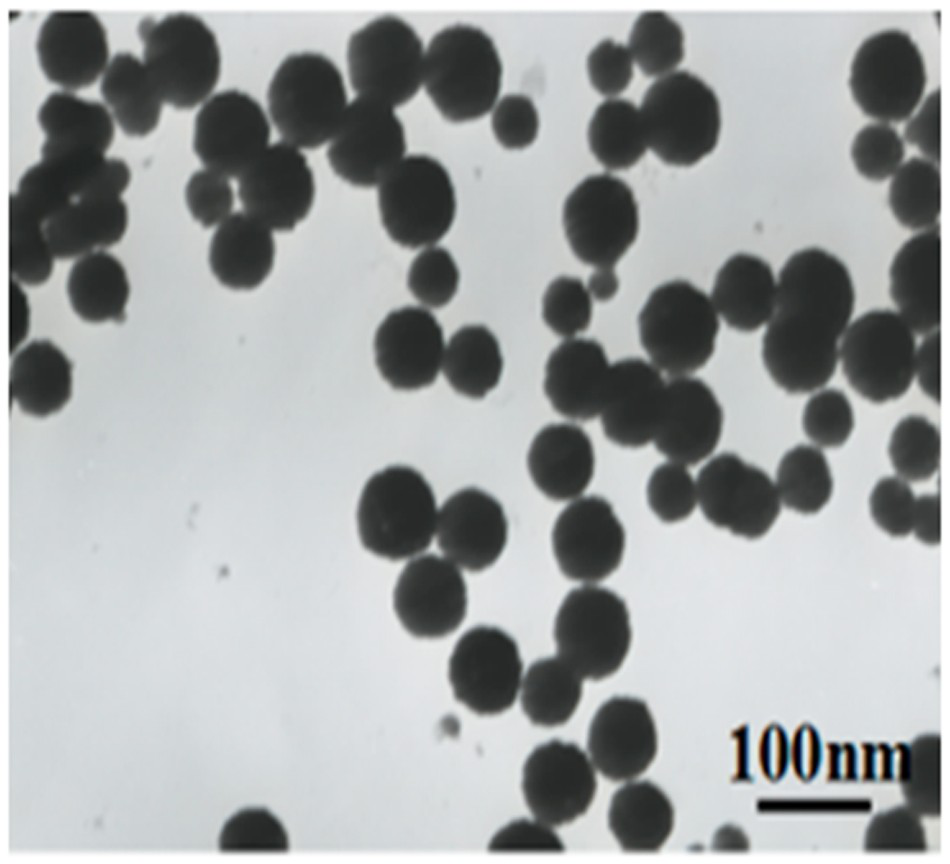

[0032] S2: Weigh 10g of nano-silica particles and disperse them into 70g of aqueous solution, add 2g of sodium persulfate, heat up to 80°C, stir and activate for 10 minutes to obtain pretreated nano-silica; detect nano-silica and obtain TEM images ,Such as figure 1 shown;

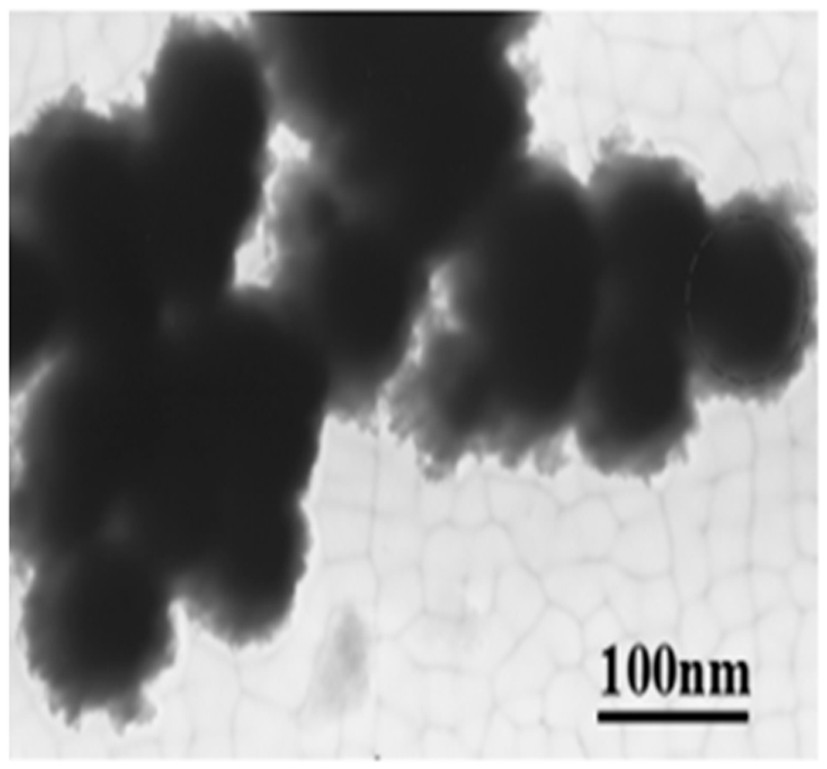

[0033] S3: adding 10 g of acrylic acid and 8 g of acrylamide monomer to the pretreated nano-silica, reacting for 8 hours, cooling and filtering, and drying in a vacuum oven at 60° C. for 6 hours to obtain polymer-modified ...

Embodiment 2

[0037] A method for preparing an ion-exchange hybrid membrane for a vanadium battery, comprising the following steps:

[0038] S1: Dry sulfonated polyether ether ketone with a sulfonation degree of 60% in a vacuum oven at 100°C for 4 hours to obtain pretreated sulfonated polyether ether ketone, and dissolve 5 g of pretreated sulfonated polyether ether ketone In 95g dimethyl sulfoxide, it is configured into a sulfonated polyether ether ketone solution with a mass concentration of 5%;

[0039] S2: Weigh 5g of nano-silica particles and disperse them into 80g of aqueous solution, add 1.5g of potassium persulfate, heat up to 86°C, stir and activate for 5min to obtain pretreated nano-silica;

[0040] S3: Add 8.5g of acrylic acid and 5g of acrylamide monomer to the pretreated nano-silica, react for 6h, cool down and filter, and dry in a vacuum oven at 60°C for 8h to obtain polymer-modified silica core-shell particles ;

[0041] S4: Add 3 g of polymer-modified silica core-shell part...

Embodiment 3

[0044] A method for preparing an ion-exchange hybrid membrane for a vanadium battery, comprising the following steps:

[0045] S1: Dry sulfonated polyether ether ketone with a sulfonation degree of 75% in a vacuum oven at 90°C for 6.5 hours to obtain pretreated sulfonated polyether ether ketone. 10 g of pretreated sulfonated polyether ether ketone Dissolved in 90g N,N-dimethylformamide, configured as a sulfonated polyether ether ketone solution with a mass concentration of 10%;

[0046] S2: Weigh 8g of nano-silica particles and disperse them into 65g of aqueous solution, add 2g of ammonium persulfate, heat up to 90°C, stir and activate for 5min, and obtain pretreated nano-silica;

[0047] S3: Add 15 g of acrylic acid and 10 g of acrylamide monomer to the pretreated nano-silica, react for 4 hours, cool down and filter, and dry in a vacuum oven at 80°C for 8 hours to obtain polymer-modified silica core-shell particles;

[0048] S4: Add 4g of polymer-modified silica core-shell par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com