Low-dielectric-loss flexible thermosetting binder and preparation method thereof

A thermosetting, low-dielectric technology, used in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., which can solve the problem of small modification space, single molecular structure design, and water absorption. problems such as being too large, to achieve the effect of simple and easy preparation method, unlimited source of raw materials, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

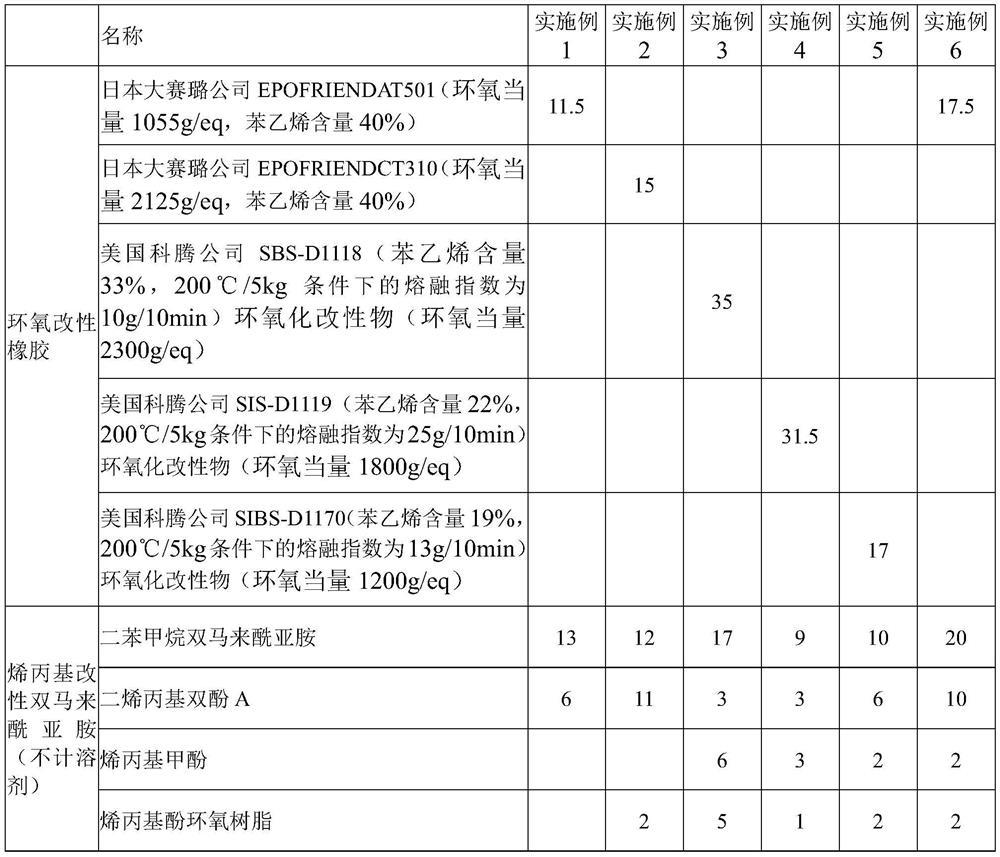

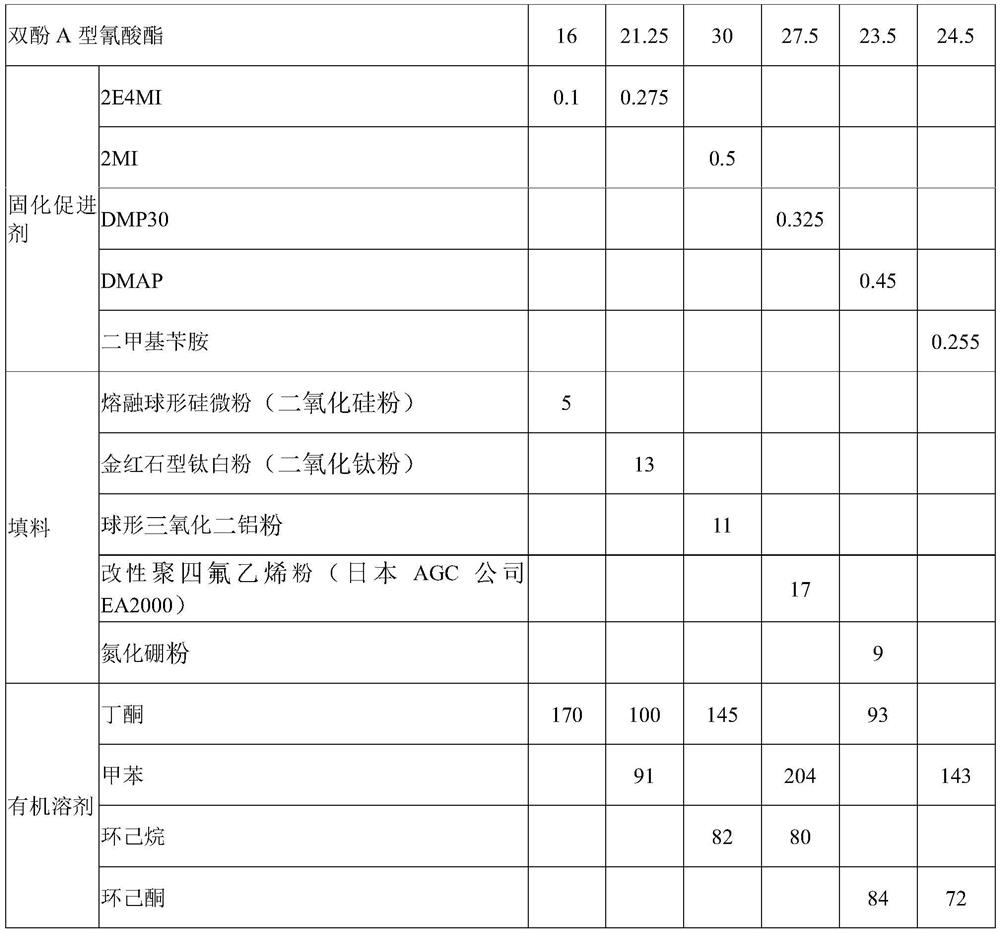

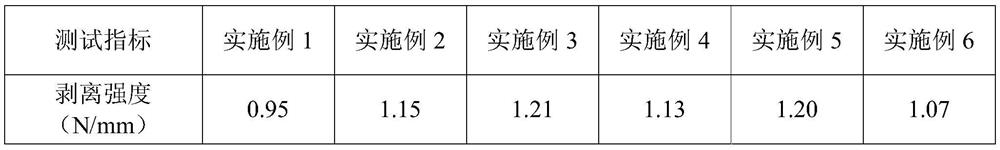

[0022] In order to enable those skilled in the art to better understand the technical solution of the present invention, the following will describe in detail, but the protection scope of the present invention is not limited thereto.

[0023] The main source of raw material for preparing low dielectric loss flexible thermosetting adhesive in the present invention is as follows:

[0024] (1) Allyl modified bismaleimide: 1-20 parts by mass of allyl modification (diallyl bisphenol A, allyl cresol, allylphenol epoxy One or more of the resins) are put into a mixed solvent of toluene and xylene with an azeotropic point of 140° C., heated and stirred at 137° C. until fully dissolved to form a 20-40 wt % solution. Add 5-30 parts by mass of diphenylmethane bismaleimide (BDM) powder into the solution, stir at 137° C. for 0.5 h, then cool to room temperature to form allyl-modified bismaleimide.

[0025] (2) Epoxy-modified rubber: the grades of Daicel Corporation in Japan can be directly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com