Quaternary high-entropy alloy containing nano-particle structure and preparation method of quaternary high-entropy alloy

A nanoparticle and high-entropy alloy technology, applied in the field of high-entropy alloy materials, can solve the problems of quaternary high-entropy alloy mechanical properties, element segregation, and complex mixing enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

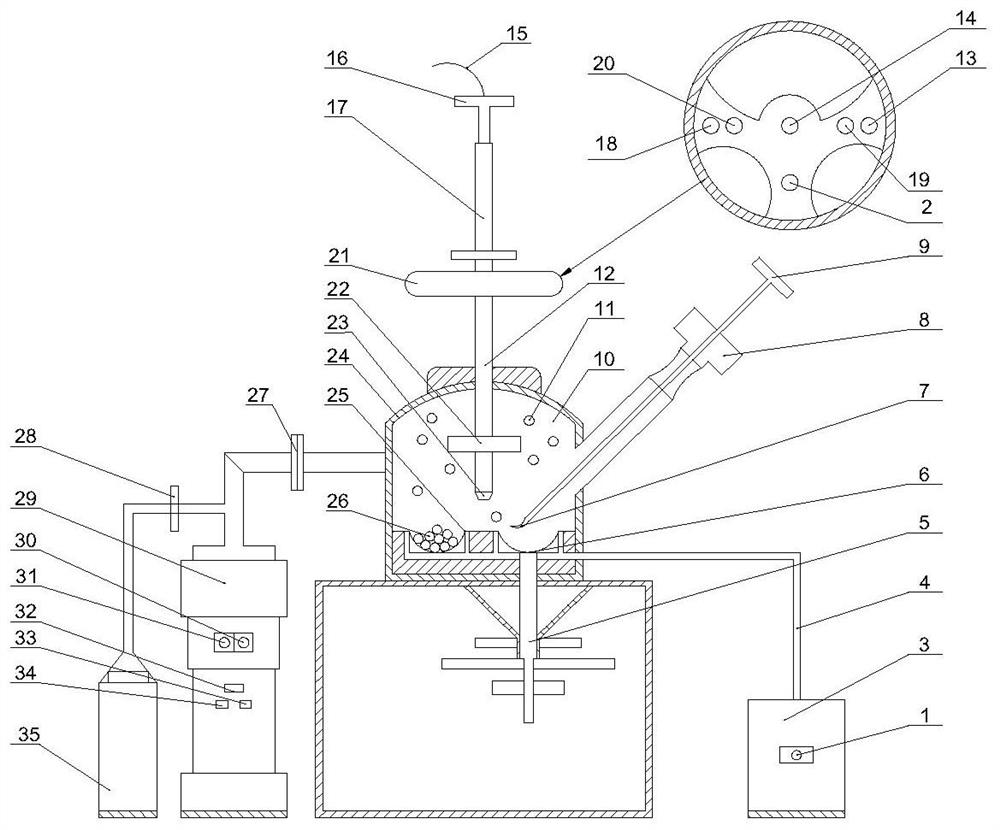

[0028] The present invention provides a method of preparing a quadroyan high entropy alloy containing a nanoparticle structure, comprising the steps of:

[0029] The raw materials are sequentially placed in the order of the raw material from low to high, and then the smelting is cooled, and the four-dimensional high entropy alloy containing the nanoparticle structure is obtained; the number of smelts is 3 to 6 times; each melting The rear cooling mode is water cooled; the quaternary high entropy alloy is an aluminum-chromium ferri-nickel tetra-high entropy alloy.

[0030] In the present invention, the tetram high entropy alloy is an aluminum-chromium ferri-nickel tetram high entropy alloy, and the atomic ratio of aluminum chromium ferriite in the high entropy alloy alloy is 1: 1: 1: 1. In the present invention, the feedstock preferably includes aluminum particles, chromium particles, iron particles, and nickel particles. The present invention has no particular limitation of the pa...

Embodiment 1

[0046] A method of preparing a quadroyan high entropy alloy containing a nanoparticle structure, which consists of the following steps:

[0047] (1) According to the atomic ratio of aluminum chromium ferri, it is 1: 1: 1: 1, the aluminum particles are 6.966 ± 0.001 g, chromium particles 13.424 ± 0.001G, iron particles 14.458 ± 0.001G and nickel particles 15.152 ± 0.001G, will Aluminum particles, chromium particles, iron particles and nickel particles are placed in a beaker, and anhydrous ethanol is added, and the magnetic vibration device is used to clean 35min, and then the mixture of acetone and anhydrous ethanol is easily washed 20 min, and the feedstock after cleaning It is dried in a vacuum drying box, dried at 200 ° C, drying time 30 min, resulting in a raw material;

[0048] (2) Wipe the molten pool and water-cooled copper mold assist in vacuum arc melting furnace with anhydrous ethanol, and the inner wall of the furnace cavity, then use the grinding wheel to polish the tip...

Embodiment 2

[0063] The high purity argon was charged in step (2) to maintain 0.9 pneumatic pressure in the furnace, other conditions and Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com