Novel ultrahigh-voltage-resistant electrolyte as well as preparation method and application thereof

An electrolyte and ultra-high voltage technology, which is applied in the direction of electrolyte, secondary battery manufacturing, non-aqueous electrolyte storage battery, etc., can solve the problems of ternary electrode collapse, unstable electrolyte charge and discharge, etc., and achieve excellent cycle performance and operation Simple, excellent cycle performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of high-voltage perfluorinated electrolyte: all reagents are stored in a glove box, and the preparation process is also carried out in the glove box. Prepare lithium hexafluorophosphate solution A by preparing lithium hexafluorophosphate salt and main solvent methyl trifluoroethyl carbonate at a mass ratio of 1:3, then add the first co-solvent (fluorinated ethylene carbonate) and lithium hexafluorophosphate at a mass ratio of 1:1 and mix evenly to obtain For solution B, add the second co-solvent (fluorinated borate) equal in quality to the first co-solvent to obtain a high-pressure perfluorinated borate-containing electrolyte.

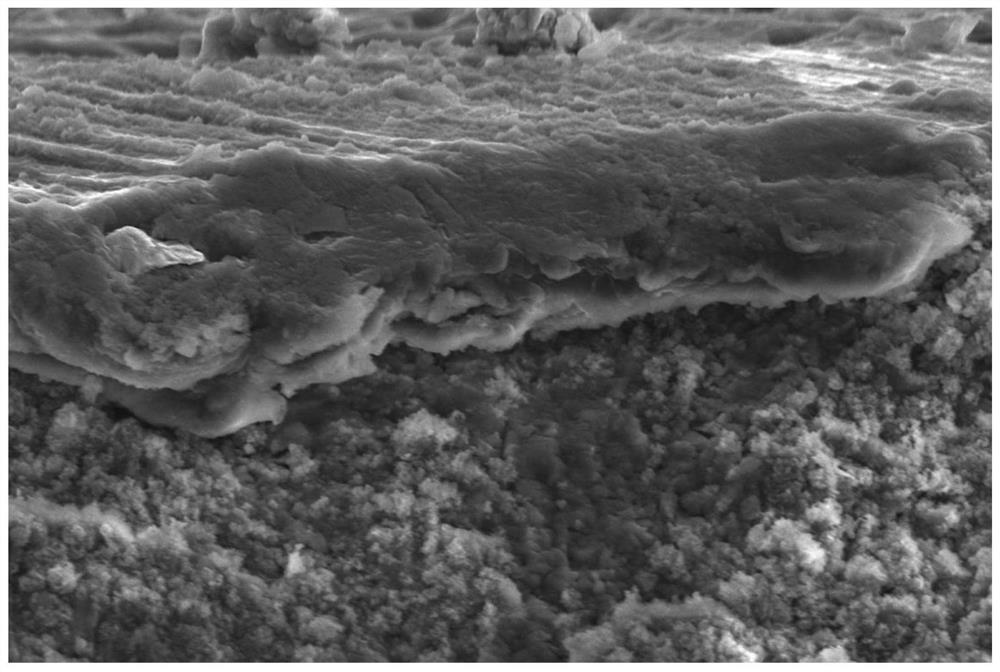

[0031](2) Assembling a ternary button lithium battery: use a battery case of model 2025, a polyethylene diaphragm, and an NCM811 ternary positive electrode with an active material of 3 mg. The negative electrode uses a lithium sheet with a thickness of 150-300 μm, and the polyethylene diaphragm is placed on the positive electrode....

Embodiment 2

[0034] (1) Preparation of high-voltage perfluorinated electrolyte: the preparation concentration is 1-2mol L -1 Lithium hexafluorophosphate electrolyte, the volume ratio of the main solvent methyl trifluoroethyl carbonate to the first co-solvent fluorinated ethylene carbonate is 3:1, the main solvent methyl trifluoroethyl carbonate and the second co-solvent fluorinated boric acid The ester volume ratio is 3:1, and a colorless clear liquid is obtained after mixing evenly. The preparation process is completed in a glove box filled with protective gas, and the oxygen content in the glove box is kept ≤<=0.1ppm, and the water content≤<=0.1ppm.

[0035] (2) Assemble the ternary button lithium battery: select the stainless steel battery casing (2025) as the positive and negative electrode casings, punch the NCM811 positive electrode sheet with a diameter of 12mm, and prepare a polyethylene separator and a lithium sheet with a thickness of 150-300μm. The ethylene separator was placed...

Embodiment 3

[0039] (1) Preparation of high-voltage perfluorinated electrolyte: mix the lithium hexafluorophosphate salt with the main solvent methyl trifluoroethyl carbonate in a mass fraction of 1:2, and add the first co-solvent with a mass fraction of the main solvent of 1:2. The solvent fluorinated ethylene carbonate, and the second co-solvent fluorinated borate with a mass fraction ratio of 1:2 to the main solvent are finally mixed uniformly to obtain a high-pressure perfluorinated electrolyte.

[0040] (2) Assembling a ternary button lithium battery: Take 25-30 μL of the high-voltage perfluorinated electrolyte prepared in step (1) and drop it into the contact surface of the positive and negative electrodes and the polyethylene diaphragm respectively using a pipette gun. The active mass of NCM811 is 3-4 mg, and the negative electrode uses a lithium sheet with a thickness of 150-300 μm, which is then packaged to obtain a button battery.

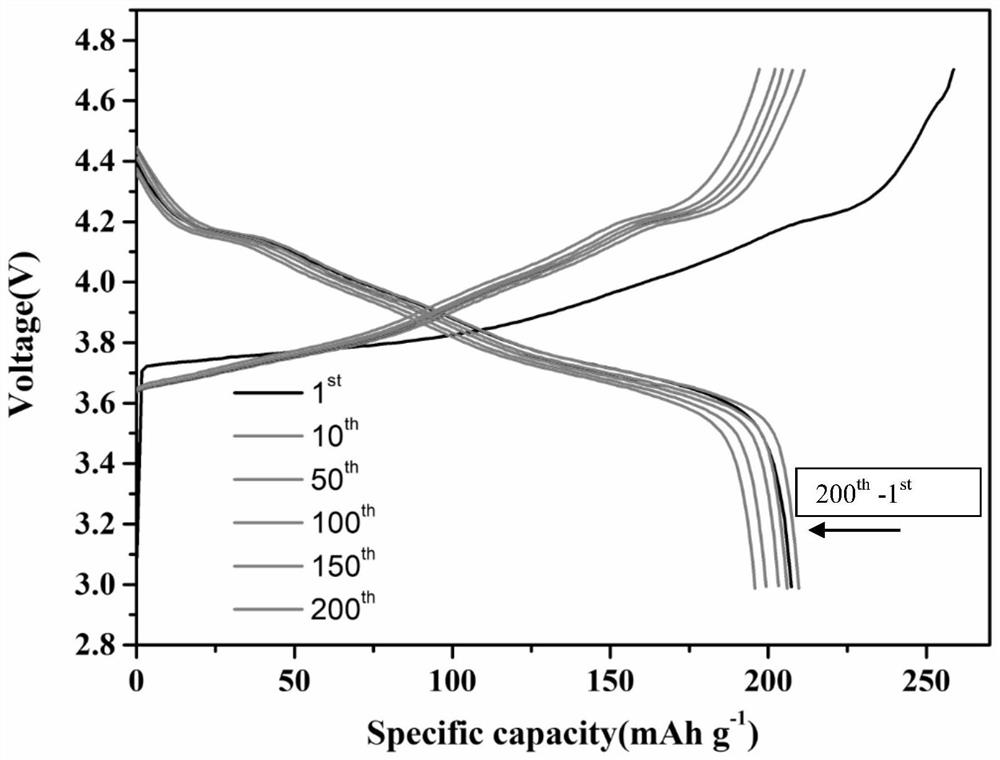

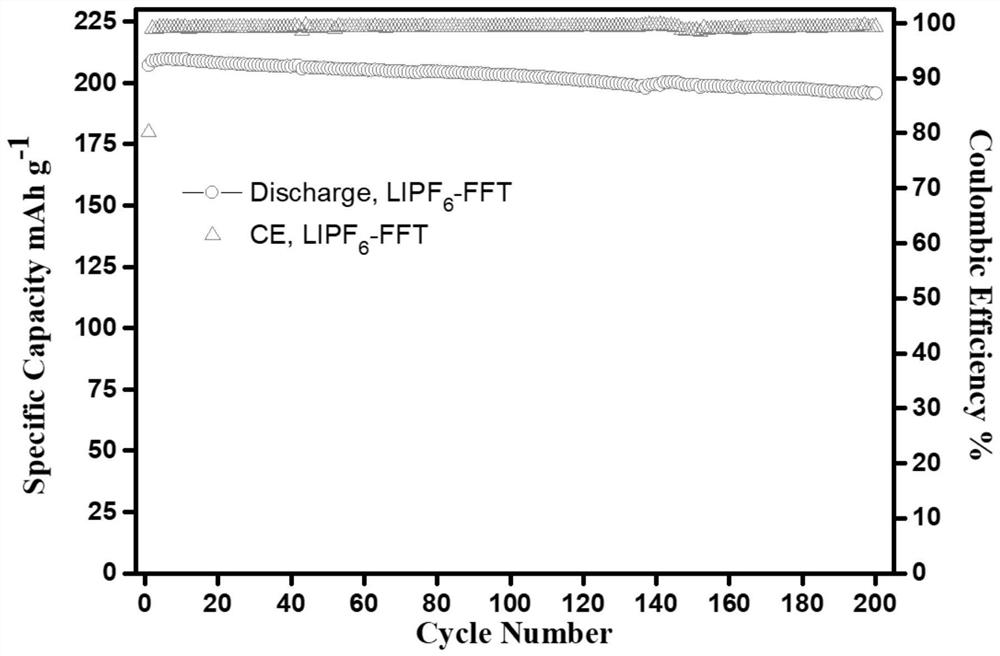

[0041] (3) Test the electrochemical performance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com