Acid-base double-site catalyst for carbon-carbon coupling reaction and application thereof

A carbon-carbon coupling and catalyst technology, used in molecular sieve catalysts, physical/chemical process catalysts, carbon-based compound preparation, etc., can solve the problem that the performance of acid-base catalysts cannot meet industrial production, and achieve the effect of excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

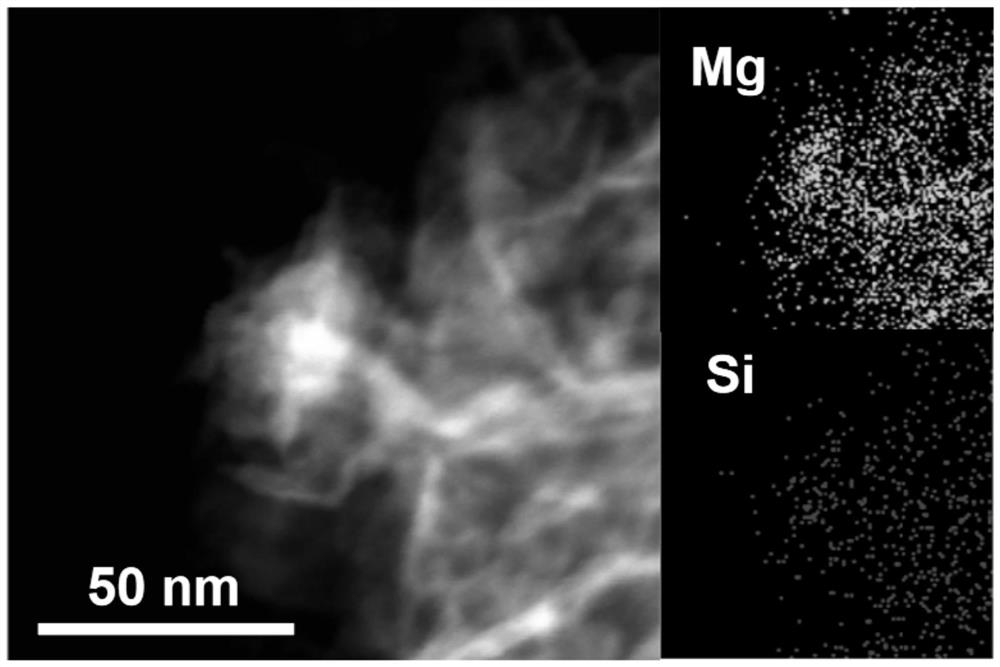

Embodiment 1

[0088] Put 2g of H-SAPO-34 molecular sieve into a ball mill with a ball-to-material volume ratio of 5, ball mill for 8 hours, and then disperse in 500mL of 2vol% ethanol aqueous solution to obtain dispersion I; the magnesium and aluminum nitrates are prepared into 1L metal salt Solution, wherein the concentrations of magnesium ions and aluminum ions are 0.15mol / L and 0.05mol / L respectively; configure 1L alkaline solution containing sodium hydroxide and sodium carbonate, wherein the concentrations of sodium hydroxide and sodium carbonate are 0.45mol / L respectively L and 0.15mol / L; add the metal salt solution and the alkali solution into the dispersion liquid Ⅰ in parallel, the dripping speed is 3mL / min, and control the pH=9~10 during the whole process; stand for aging for 10h, wash with water until neutral, pump Filtration; the resulting solid was calcined at 600 ° C for 12h. The obtained product is an acid-base double-site catalyst, wherein the weight ratio of catalyst A to ca...

Embodiment 2

[0141] Put 2.2g of H-B molecular sieve into a ball mill and mill for 6 hours, then disperse in 500mL of 2% ethanol solution to obtain dispersion I; the nitrates of magnesium, aluminum and chromium are prepared into 1L metal salt solution, in which magnesium ions, aluminum ions and The concentrations of chromium ions are 0.2mol / L, 0.05mol / L and 0.03mol / L respectively; 1L of alkaline solution containing sodium hydroxide and sodium carbonate is prepared, and the concentrations of sodium hydroxide and sodium carbonate are respectively 0.3mol / L and 0.1mol / L; add the metal salt solution and the alkali solution into the dispersion C in parallel, drop at a rate of 6mL / min, and control the pH=9 to 10 during the whole process; age, wash to neutral, and suction filter; the obtained solid Calcined at 550°C for 12h. The obtained product is an acid-base double-site catalyst, and the weight ratio of component A to component B is 5.7:1.

[0142] According to the n-butylamine titration test, ...

Embodiment 3

[0147]Put 2.3g of H-Y molecular sieves into a ball mill for 7 hours, and then disperse them in 500mL of 1% ethanol solution to obtain dispersion I; the nitrates of magnesium, aluminum and zinc are prepared into 1L metal salt solution, in which magnesium ions, aluminum ions and The concentration of zinc ions is 0.2mol / L, 0.05mol / L and 0.03mol / L respectively; configure 1L alkaline solution containing sodium hydroxide, urea and sodium carbonate, wherein the concentrations of sodium hydroxide, urea and sodium carbonate are respectively 0.45mol / L, 0.06mol / L and 0.09mol / L; add the metal salt solution and the alkali solution into the dispersion C in parallel, drop at a speed of 5 mL / min, and control the pH=9 to 10 during the whole process; aging, washing with water To neutral, filter with suction; Calcinate the resulting solid at 500°C for 12h. The obtained product is an acid-base double-site catalyst, and the weight ratio of component A to component B is 5.6:1.

[0148] According t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com