Resistive random access memory based on lead-free cesium antimony iodine perovskite and preparation method thereof

A lead-free cesium antimony iodine perovskite, resistive memory technology, applied in electrical components and other directions, can solve problems such as human and environmental hazards, restrict large-scale applications, etc., to prevent moisture and oxygen corrosion, improve stability and reliability. , the effect of good storage durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

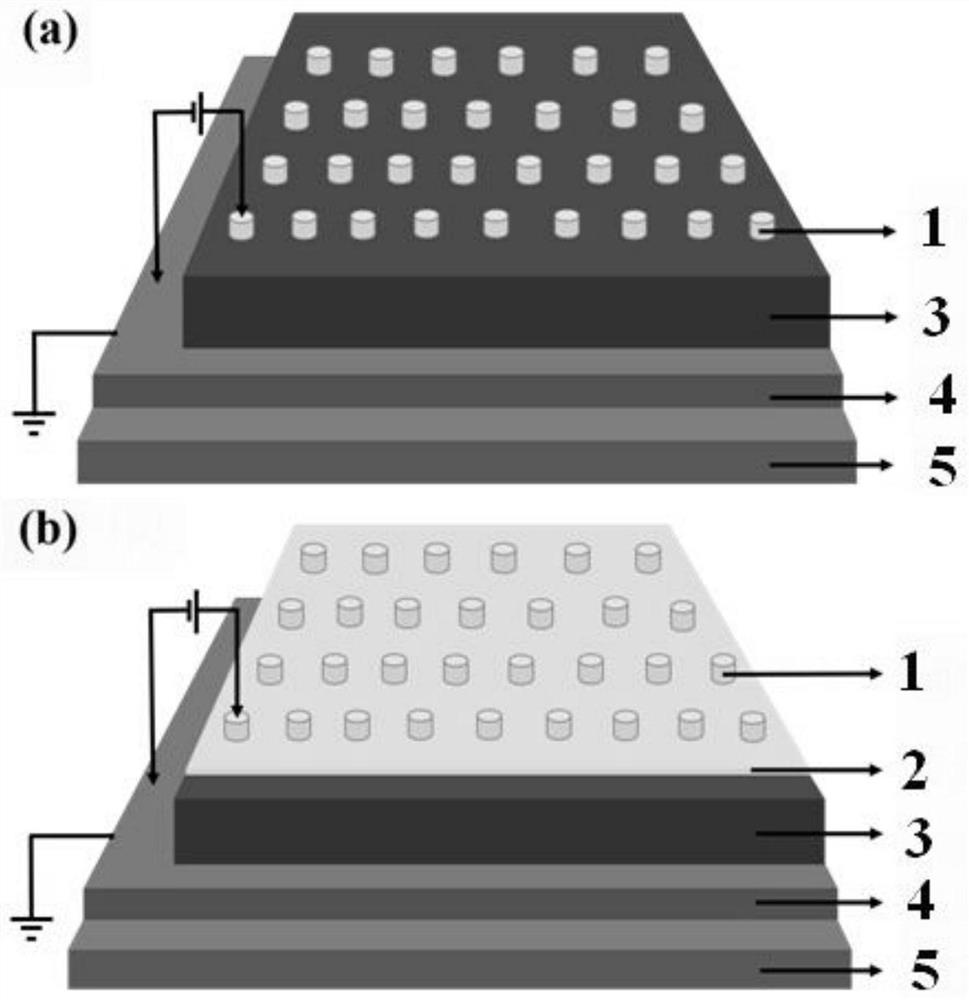

[0038] Prepare a top electrode 1 (the material is Ag, the shape is circular, the thickness is 150nm, the diameter is 300μm), Cs 3 Sb 2 I 9 Perovskite resistive layer 3 (square shape, thickness 270nm, side length 1.7cm), bottom electrode 4 (material is transparent conductive glass indium tin oxide (ITO), square shape, thickness 200nm, side length 1.7cm) and a glass substrate to form the resistive memory of lead-free cesium antimony iodine perovskite, comprising the following steps:

[0039] (1) Pretreatment of the bottom electrode (ITO) deposited on the glass substrate: the bottom electrode (ITO) deposited on the polished surface of the glass substrate (5) by magnetron sputtering is washed with detergent, Deionized water, acetone, and absolute ethanol were sonicated for 20 minutes and then dried.

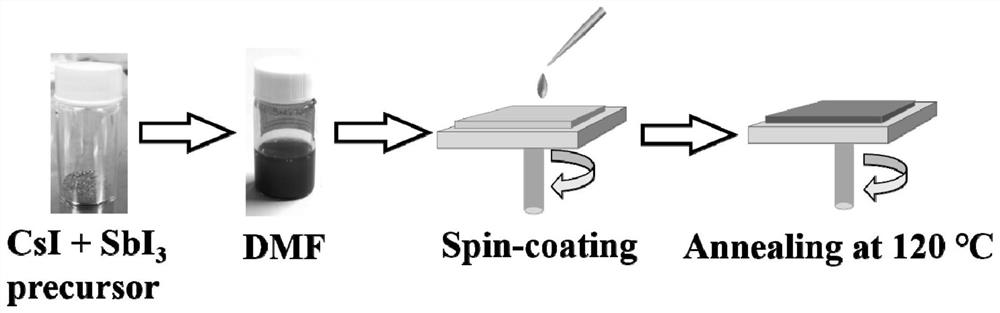

[0040] (2) if figure 1 The procedure shown for the preparation of Cs 3 Sb 2 I 9 Perovskite resistance switch layer: 0.75mmol cesium iodide (CsI) and 0.5mmol antimony iodide (S...

Embodiment 2

[0044] Prepare a top electrode 1 (made of Ag, circular in shape, 150 nm in thickness, and 300 μm in diameter), organic passivation layer 2 (made of polymethyl methacrylate, square in shape, Thickness is 10nm, side length is 1.7cm), Cs 3 Sb 2 I 9 Perovskite resistive layer 3 (square shape, thickness 270nm, side length 1.7cm), bottom electrode 4 (material is transparent conductive glass indium tin oxide (ITO), square shape, thickness 200nm, side length 1.7cm) and glass substrate composed of lead-free cesium antimony iodine perovskite resistive memory, its structure is as figure 2 As shown in b, the resistive memory consists of top electrode, organic passivation layer, Cs 3 Sb 2 I 9 The perovskite resistive layer and the bottom electrode are composed of the following steps:

[0045] (1) Pretreatment of the bottom electrode (ITO) deposited on the glass substrate: the bottom electrode (ITO) deposited on the polished surface of the glass substrate (5) by magnetron sputtering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com