Preparation and application of two-aqueous-phase porous pancreas islet microcapsule with core-shell structure

A core-shell structure and microcapsule technology, which is applied in the field of porous pancreatic islet microcapsules and their preparation, can solve the problems of complex preparation of hydrogel microspheres, low transplantation survival rate, decreased cell activity, etc., and achieves low price and repeatability. High, simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

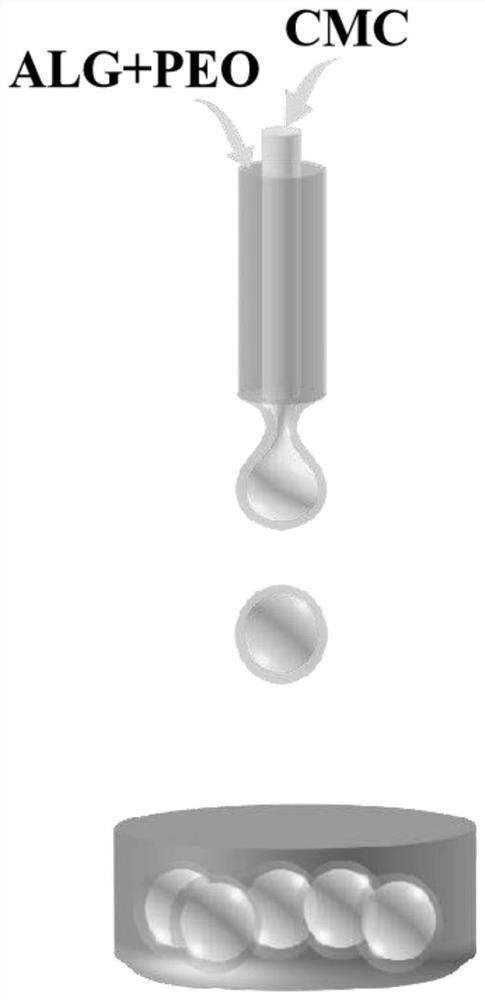

[0035] Preparation of porous islet microcapsules with core-shell structure

[0036] (1) Design of microfluidic chip:

[0037] First design the microfluidic EFI chip, select capillary glass tubes with diameters of 800 microns and 300 microns, adjust the outlet of the external phase capillary to 500 microns by pulling the tube, and use the coaxial method to nest the capillary tubes with two diameters. The coaxial capillary is pasted and fixed with a needle at the corresponding place, leaving the inlet of the two-phase solution. Such as figure 1 shown. Repeated washing with ultrapure water to obtain a microfluidic chip.

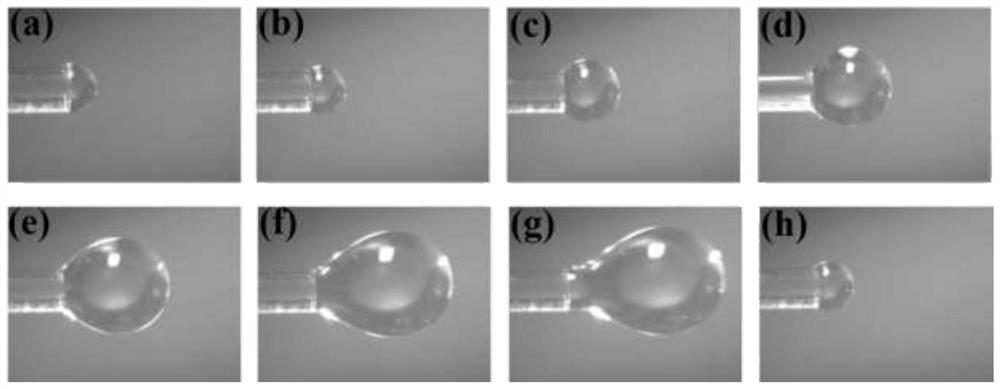

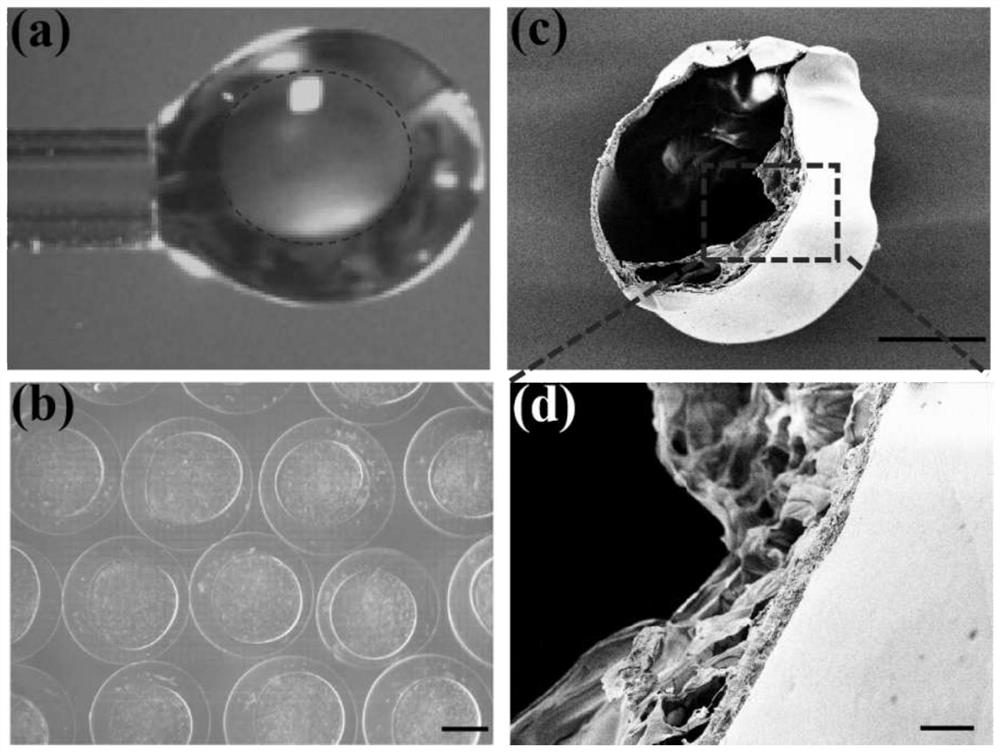

[0038] (2) Preparation of porous islet microcapsules with core-shell structure:

[0039] In order to make the shell hydrogel have a porous structure, add a small amount of 1% (w / v) PEO solution to the prepared 1% (w / v) sodium alginate solution, stir overnight, and mix the two solutions well; prepare 1% (w / v) sodium carboxymethyl cellulose solution, build a ...

Embodiment 2

[0041] Preparation of porous islet microcapsules with core-shell structure

[0042] (1) Design of microfluidic chip:

[0043] First design the microfluidic EFI chip, select capillary glass tubes with diameters of 800 microns and 300 microns, adjust the outlet of the external phase capillary to 500 microns by pulling the tube, and use the coaxial method to nest the capillary tubes with two diameters. The coaxial capillary is pasted and fixed with a needle at the corresponding place, leaving the inlet of the two-phase solution. Such as figure 1 shown. Repeated washing with ultrapure water to obtain a microfluidic chip.

[0044] (2) Preparation of porous islet microcapsules with core-shell structure:

[0045] In order to make the shell hydrogel have a porous structure, prepare polyethylene glycol diacrylate (PEGDA) solutions with different concentration ranges, add a small amount of 1% (w / v) PEO solution, stir overnight, and make the two solutions fully mix evenly; Prepare a...

Embodiment 3

[0047] Preparation of porous islet microcapsules with core-shell structure

[0048] (1) Design of microfluidic chip:

[0049]First design the microfluidic EFI chip, select capillary glass tubes with diameters of 800 microns and 300 microns, adjust the outlet of the external phase capillary to 500 microns by pulling the tube, and use the coaxial method to nest the capillary tubes with two diameters. The coaxial capillary is pasted and fixed with a needle at the corresponding place, leaving the inlet of the two-phase solution. Such as figure 1 shown. Repeated washing with ultrapure water to obtain a microfluidic chip.

[0050] (2) Preparation of porous islet microcapsules with core-shell structure

[0051] In order to make the shell hydrogel have a porous structure, prepare gelatin methacrylate (GelMA) solutions of different concentrations, add a small amount of 1% (w / v) PEO solution, stir overnight, and mix the two solutions well; prepare 1% (w / v) sodium carboxymethyl cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com