Spinel type ZnFeMnO4 nano material, and preparation method and application thereof

A nano-material and spinel-type technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of poor chemical stability, poor activation of PMS performance, large consumption of PMS, etc., to achieve highly selective degradation, Good pollutant removal effect, low efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a spinel type ZnFeMnO 4 The preparation method of nanometer material, comprises the following steps:

[0033] A) stirring and mixing zinc acetylacetonate, iron acetylacetonate, manganese acetylacetonate and an ethylene glycol solution containing polyvinylpyrrolidone to obtain a mixed solution;

[0034] B) reacting the mixed solution at 185-190°C;

[0035] C) Calcining the reacted solid product to obtain spinel ZnFeMnO 4 nanomaterials.

[0036] In the invention, zinc acetylacetonate, iron acetylacetonate, manganese acetylacetonate and ethylene glycol solution containing polyvinylpyrrolidone are first stirred and mixed to obtain a mixed solution.

[0037] In the present invention, the polyvinylpyrrolidone (PVP) is used as a surfactant to control the morphology and growth of crystals.

[0038] In some embodiments of the present invention, the average molecular weight of the polyvinylpyrrolidone is 50000-60000 g / mol. In certain embodiments, the p...

Embodiment 1

[0076] Spinel ZnFeMnO 4 Preparation of nanomaterials:

[0077] Dissolve 0.3g of polyvinylpyrrolidone (average molecular weight of 58000g / mol) in 150mL of ethylene glycol, add 1.5mmol of zinc acetylacetonate, 1.5mmol of iron acetylacetonate and 1.5mmol of manganese acetylacetonate after the solution is clarified, and stir for 2 hours. Heat the reaction in an oil bath at 190°C for 6 hours, collect and wash the solid product by centrifugation (washing three times with water and three times with ethanol), dry it in vacuum for 12 hours, and calcinate at 500°C in air for 3 hours to obtain spinel-type ZnFeMnO 4 nanomaterials.

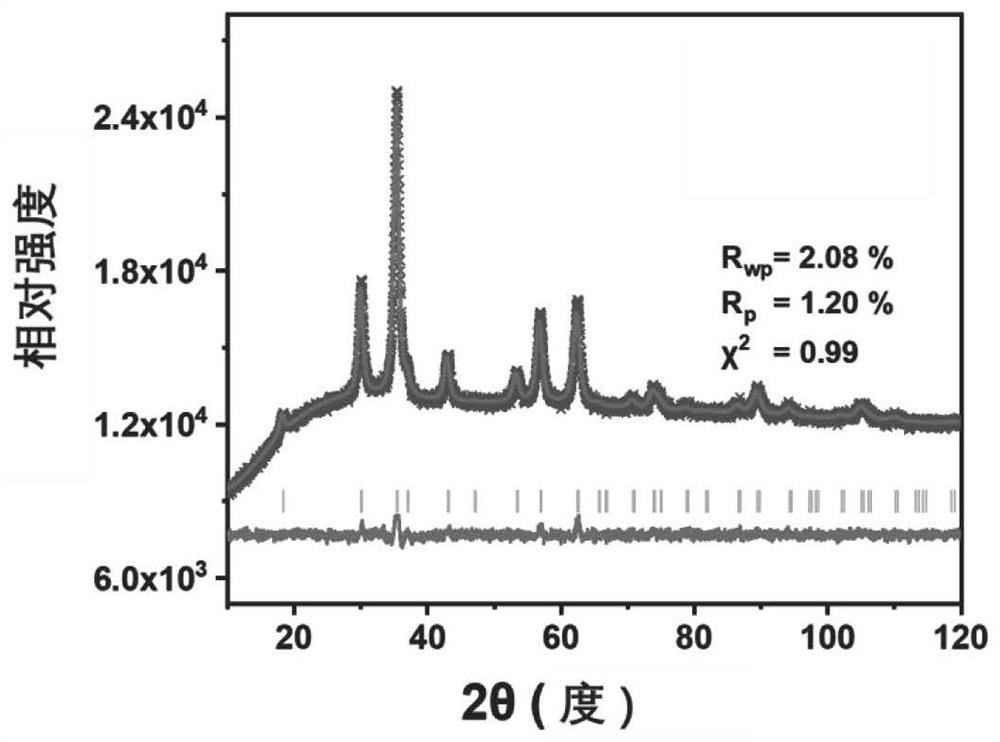

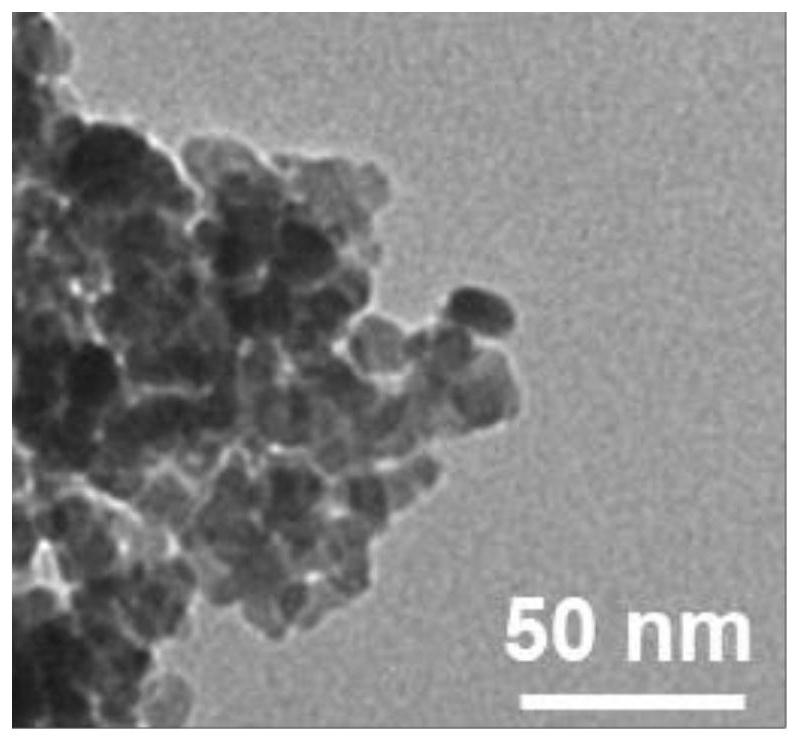

[0078] The resulting spinel ZnFeMnO 4 After the nanomaterials are ground uniformly, X-ray diffraction (XRD) analysis and transmission electron microscope (TEM) analysis are performed. figure 1 Be the spinel type ZnFeMnO of the embodiment 1 of the present invention 4 XRD patterns of nanomaterials. from figure 1 It can be seen that the Mn element is succe...

Embodiment 2

[0082] Spinel ZnFeMnO 4 Performance and mechanism of nanomaterials activated PMS to degrade bisphenol A:

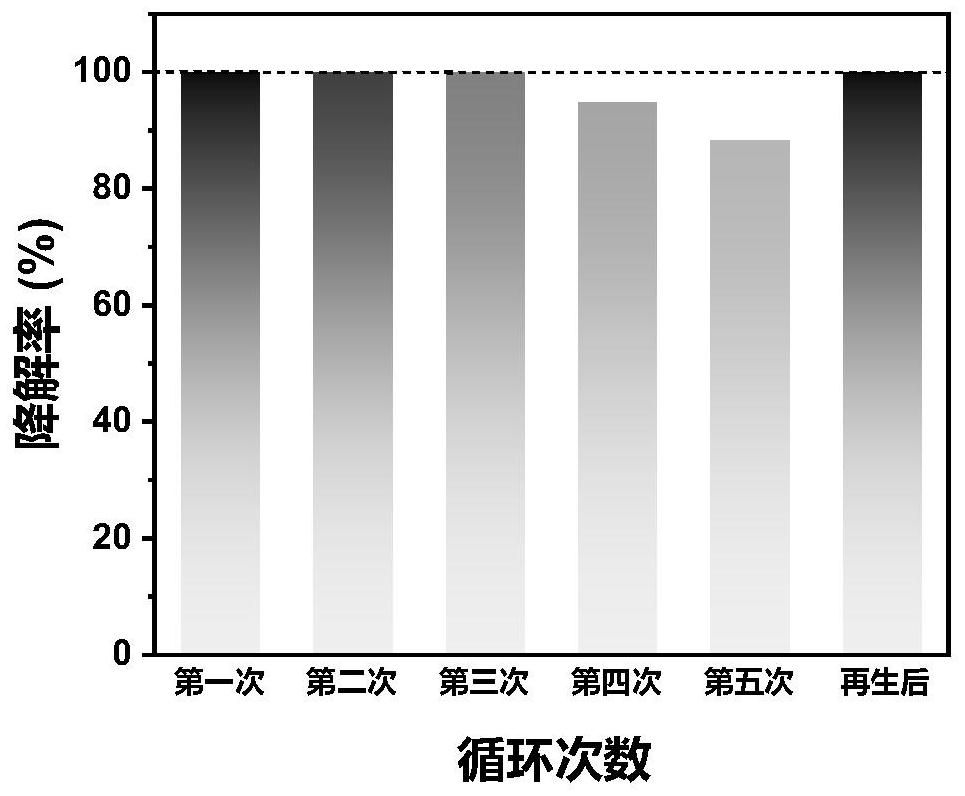

[0083] (1) Degrade bisphenol A (BPA): get the spinel type ZnFeMnO of embodiment 1 4 Ultrasonic dispersion of 2mg of nanomaterials in 20mL of 10mg / L bisphenol A solution (solvent is deionized water), stirring for 15min to reach adsorption equilibrium, adding 1mg of persulfate (PMS), reacting at room temperature, taking fixed Quantitative reaction solution (referring to be mixed with ZnFeMnO in the above-mentioned reaction 4 and the reaction solution of bisphenol A of PMS) to join mass concentration as 2% Na 2 SO 3 The reaction was terminated in solution and the BPA concentration was tested using HPLC. After reacting for 15 minutes, the catalyst was collected by centrifugation, washed with deionized water, and then the above steps were repeated. A total of 5 cycles of testing were performed, and the reaction time of each cycle was 15 minutes. The material collected aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com