Preparation method of anti-icing durable super-hydrophobic coating layer

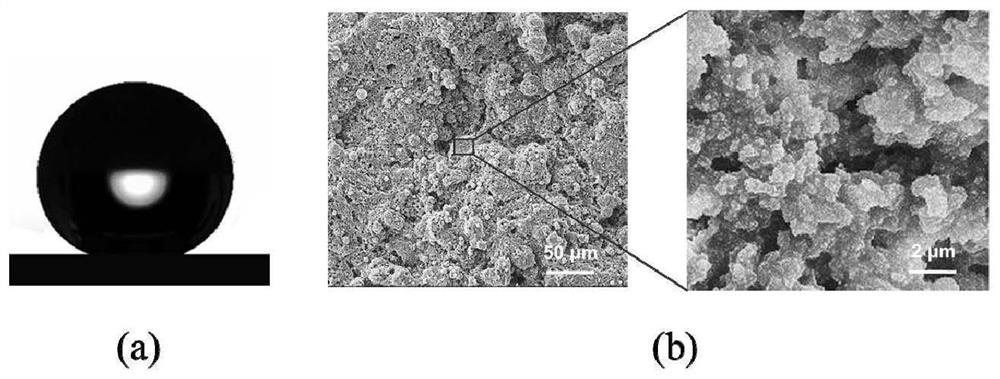

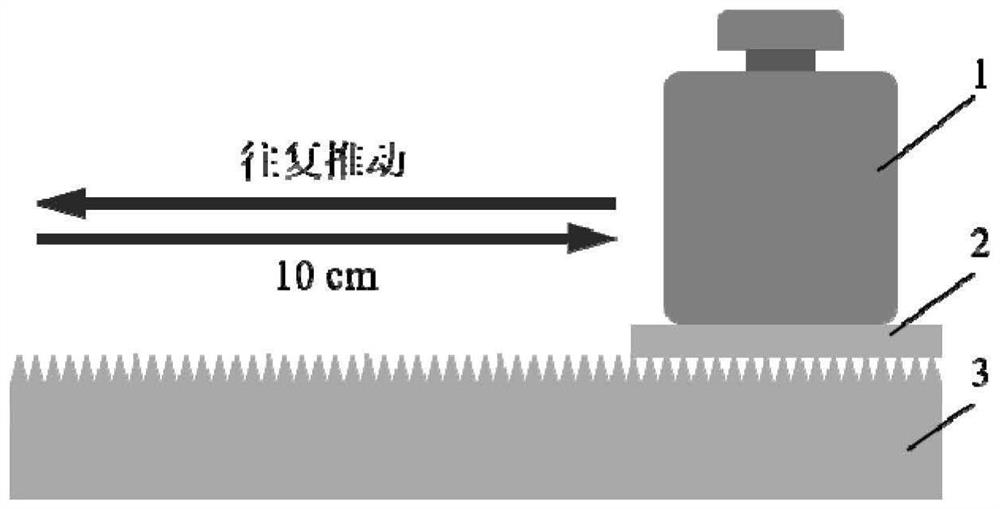

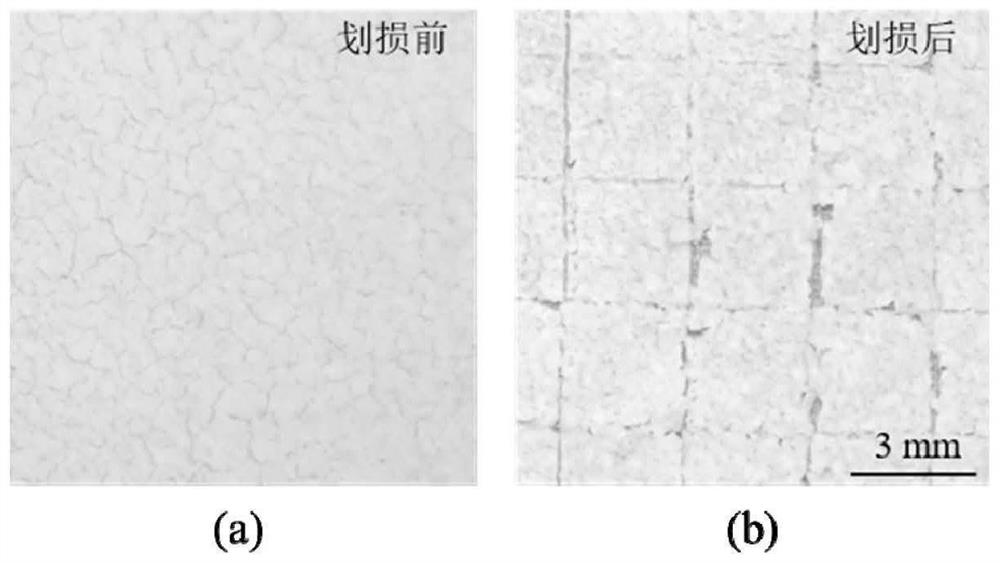

A super-hydrophobic coating and anti-icing technology, applied in coatings, epoxy resin coatings, sustainable manufacturing/processing, etc., can solve the problems of fragile micro-nano structures, poor mechanical stability, and easy damage on super-hydrophobic surfaces , to achieve good industrial prospects, stable mechanical properties, simple and easy to obtain the effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method for an anti-icing durable superhydrophobic coating, comprising the following specific steps:

[0037] In this implementation case, a 6061 aluminum alloy plate of 40mm×40mm×1mm was selected as the base material, cleaned with acetone, deionized water and ethanol, dried and placed on the spraying platform;

[0038] Mix 3g of E-51 epoxy resin with 7g of methylvinyl MQ silicone resin, measure 15mL of butyl acetate as the first solvent to disperse the mixed resin evenly, and stir for 1 hour with a magnetic stirrer to obtain a mixed resin solution;

[0039] Weigh 2.5g of silica particles according to the mass ratio of composite silica particles to mixed resin of 1:4, and mix them with silica particles of 7-40nm and 200-500nm in a ratio of 7:3. Use 25mL of ethanol solution as the second solvent to disperse the silica particles evenly, and add 1mL of ammonia water to the dispersion system. Using a magnetic stirrer to stir for 2 hours to obtain a particle co...

Embodiment 2

[0058] A preparation method for an anti-icing durable superhydrophobic coating, comprising the following specific steps:

[0059] In this implementation case, a 20mm×20mm×1mm wooden board was selected as the base material, cleaned with acetone, deionized water and ethanol, dried and placed on the spraying platform;

[0060] Mix 4g of NPEF-170 epoxy resin with 4g of methylphenylpolysiloxane resin, measure 20mL of ethyl acetate as the first solvent to disperse the mixed resin evenly, and stir for 2h with a magnetic stirrer to obtain a mixed resin solution;

[0061] Weigh 1.6g of silica particles according to the mass ratio of composite silica particles to mixed resin of 1:5, and mix them with silica particles of 7-40nm and 200-500nm in a ratio of 2:1. Use 10 mL of ethanol solution as the second solvent to disperse the silica particles evenly, and add 0.3 mL of ammonia water to the dispersion system. Using a magnetic stirrer to stir for 1 h to obtain a particle composite suspens...

Embodiment 3

[0065] A preparation method for an anti-icing durable superhydrophobic coating, comprising the following specific steps:

[0066] In this implementation case, a 60mm×40mm×0.5mm tinplate plate was selected as the base material, cleaned with acetone, deionized water and ethanol, dried and placed on the spraying platform;

[0067] Mix 2g of E-51 epoxy resin with 10g of methylphenylpolysiloxane resin, measure 20mL of butyl acetate as the first solvent to disperse the mixed resin evenly, and stir for 3 hours with a magnetic stirrer to obtain a mixed resin solution;

[0068] Weigh 3.6g of silica particles according to the mass ratio of composite silica particles to mixed resin of 3:10, and mix them with silica particles of 7-40nm and 200-500nm in a ratio of 10:1. Use 24mL of ethanol solution as the second solvent to disperse the silica particles evenly, and add 1.2mL of ammonia water to the dispersion system. Using a magnetic stirrer to stir for 3 hours to obtain a particle composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com