Magnetic phase-change nano material and preparation method thereof

A technology of nanomaterials and magnetic phase transitions, applied in the direction of magnetic materials, magnetic objects, magnetic liquids, etc., can solve the problems of poor thermal stability and thermal conductivity, and achieve the effect of improving thermal conductivity, simple preparation method, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing magnetic phase-change nanomaterials, comprising the following steps:

[0026] (1) Steps for preparing magnetic graphene oxide (rGO): dissolve graphene oxide (GO), ferric chloride, sodium acrylate and sodium acetate in a mixed solvent of ethylene glycol and diethylene glycol (ethylene glycol / diethylene glycol The alcohol volume ratio is 0.5% to 60%: 1) to obtain a mixed solution;

[0027] Wherein, the mass volume ratio of graphene oxide and mixed solvent is 0.05%~10%wt / v, the mass volume ratio of ferric chloride and mixed solvent is 0.1%~10%wt / v, the mass volume ratio of sodium acrylate and mixed solvent The volume ratio is 1%-15%wt / v, the mass volume ratio of sodium acetate to mixed solvent is 1%-15%wt / v; the volume ratio of ethylene glycol to diethylene glycol is 0.005-0.6:1.

[0028] Then transfer the obtained solution to a stainless steel autoclave lined with Teflon, seal it and heat it at 120-280°C for 4-48h, wash it with ethanol and deionize...

Embodiment 1

[0038] The prepared GO (1% wt / v), ferric chloride (0.8% wt / v), sodium acrylate (4% wt / v) and sodium acetate (4% wt / v) were dissolved in ethylene glycol and di Glycol mixed solvent (ethylene glycol / diethylene glycol volume ratio is 50%:1). The resulting solution was then transferred into a Teflon-lined stainless steel autoclave, which was sealed and heated at 150 °C for 8 h. Wash twice with ethanol and deionized water, and dry in vacuum before use. Disperse the magnetic graphene oxide in water (1% wt / v), add epichlorohydrin (3% wt / v), and react at room temperature for 8 hours to obtain magnetic graphene oxide modified with epoxy groups.

[0039] The epoxy group-modified magnetic graphene oxide was dispersed in water (1% wt / v), 1,22-docosanediol (5% wt / v) was added, and reacted at 50°C for 8h, and then mixed with ethanol and removed The magnetic nanomaterials were obtained after washing with ion water and vacuum drying.

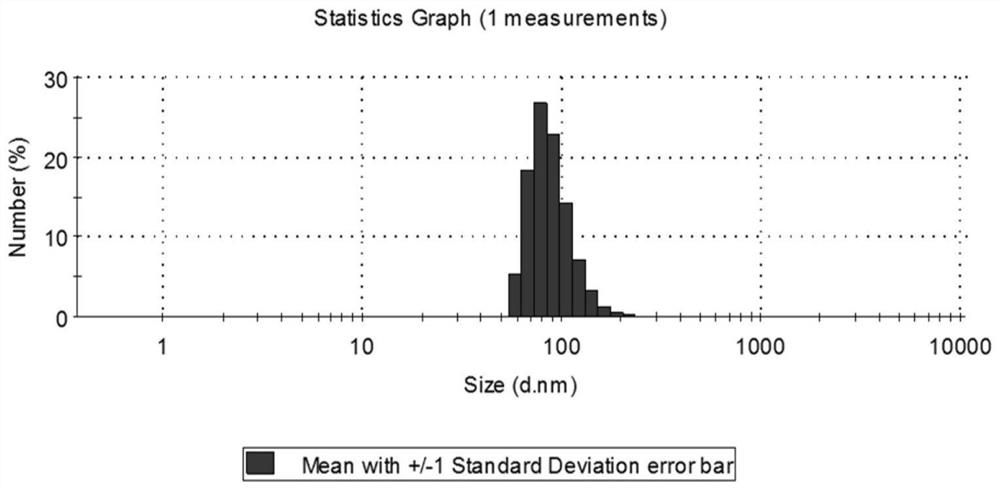

[0040] From figure 1 It can be seen that the particle...

Embodiment 2

[0042] The prepared GO (0.5% wt / v), ferric chloride (0.1%), sodium acrylate (1% wt / v) and sodium acetate (5% wt / v) were dissolved in ethylene glycol and diethylene glycol mixed In solvent (ethylene glycol / diethylene glycol volume ratio is 30%:1). The resulting solution was then transferred into a Teflon-lined stainless steel autoclave, which was sealed and heated at 200 °C for 4 h. Wash 3 times with ethanol and deionized water, dry in vacuum and set aside. Disperse magnetic graphene oxide in DMSO (0.5%), add epichlorohydrin (0.8% wt / v), and react at room temperature for 12 hours to obtain magnetic graphene oxide modified with epoxy groups.

[0043] The epoxy group-modified magnetic graphene oxide was dispersed in DMSO (0.9%wt / v), added 1,12-octadecanediol (30%wt / v), reacted at 80°C for 1.5h, and mixed with ethanol and After washing with deionized water and vacuum drying, the magnetic nanomaterials were prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com