Viscosity reduction type ester ether copolymerized polycarboxylic acid water reducer and normal-temperature preparation method thereof

A technology of ester ether copolymerization of polycarboxylic acid and water reducing agent, applied in the field of water reducing agent, can solve the problems of many side reactions, influence of application performance and high impurity content, achieve good industrial value, improve later application performance, and reduce reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

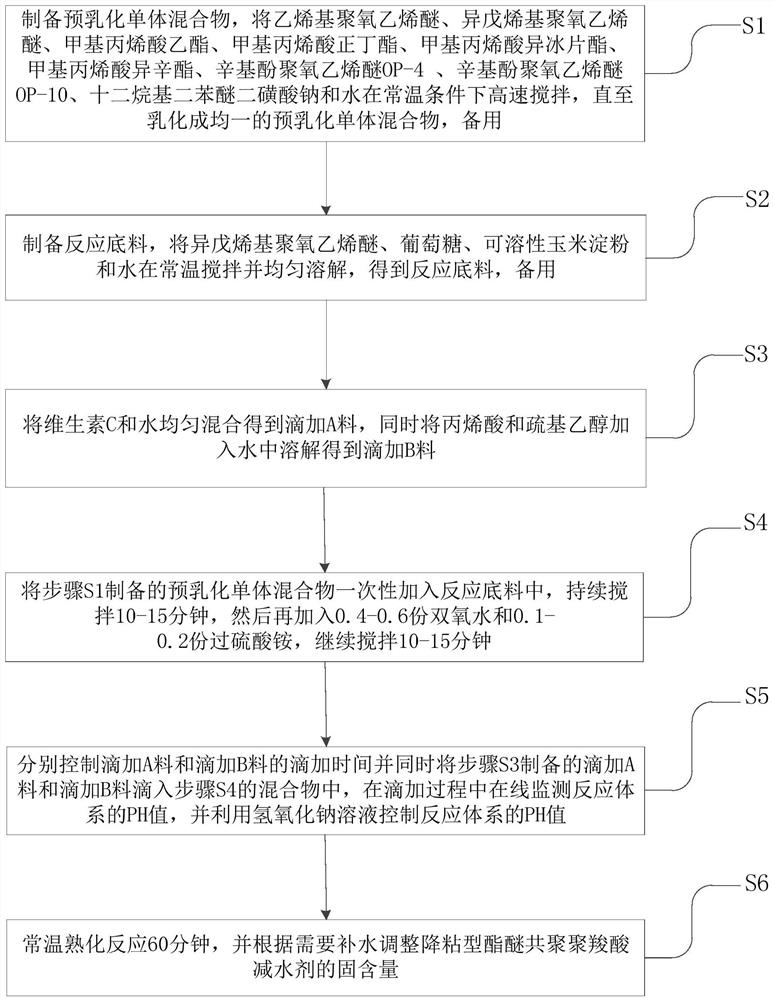

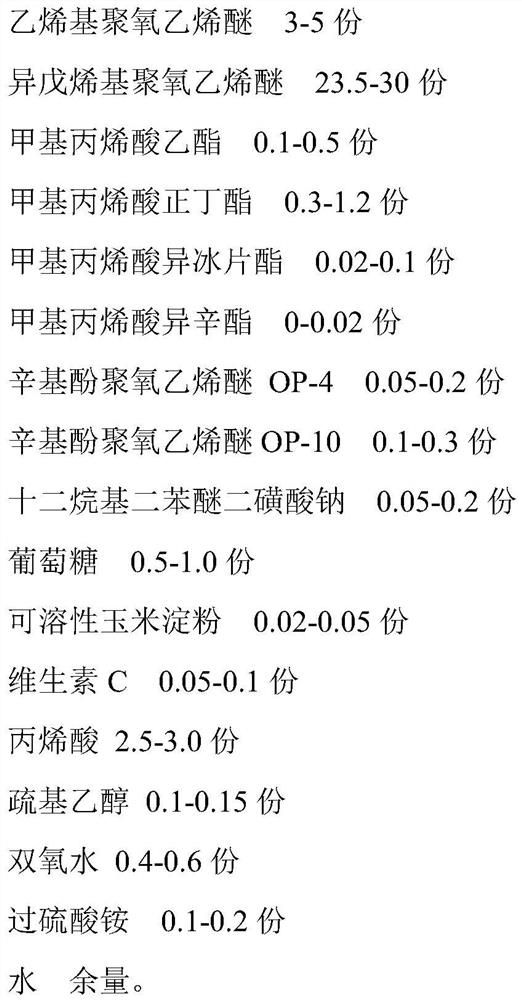

Method used

Image

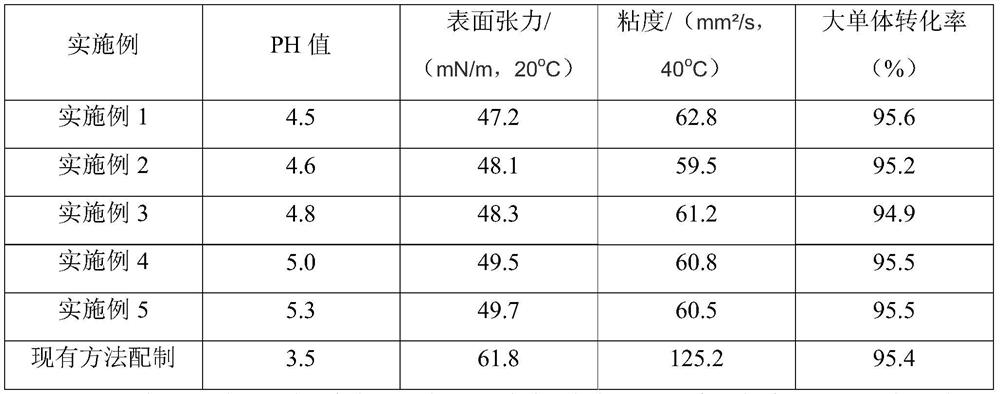

Examples

Embodiment 1

[0039] S1. To prepare a pre-emulsified monomer mixture, 3 parts of vinyl polyoxyethylene ether, 2 parts of isopentenyl polyoxyethylene ether, 0.5 parts of ethyl methacrylate, 1.2 parts of n-butyl methacrylate, methacrylic acid 0.1 part of isobornyl ester, 0.02 part of isooctyl methacrylate, 0.2 part of octylphenol polyoxyethylene ether OP-4, 0.3 part of octylphenol polyoxyethylene ether OP-10, dodecyl diphenyl ether disulfonate 0.2 parts of sodium bicarbonate and 10 parts of water are stirred at high speed at room temperature until the above reagents are emulsified into a uniform emulsion, and set aside;

[0040] S2. Prepare the reaction base material by stirring and uniformly dissolving 23 parts of isopentenyl polyoxyethylene ether, 1 part of glucose, 0.02 part of soluble cornstarch and 18 parts of water at room temperature to obtain the reaction base material, which is set aside;

[0041] S3. Uniformly mix 0.1 part of vitamin C and 8 parts of water to obtain dropwise materia...

Embodiment 2

[0046] S1. To prepare a pre-emulsified monomer mixture, 5 parts of vinyl polyoxyethylene ether, 1.5 parts of isopentenyl polyoxyethylene ether, 0.4 part of ethyl methacrylate, 1.0 part of n-butyl methacrylate, methacrylic acid 0.08 parts of isobornyl ester, 0.01 parts of isooctyl methacrylate, 0.15 parts of octylphenol polyoxyethylene ether OP-4, 0.2 parts of octylphenol polyoxyethylene ether OP-10, 0.15 parts of sodium dodecyl diphenyl ether disulfonate Stir with 8 parts of water at high speed at room temperature until the above reagents are emulsified into a uniform emulsion, and set aside;

[0047] S2. Prepare the reaction base material. Stir and dissolve 25 parts of isopentenyl polyoxyethylene ether, 0.9 part of glucose, 0.04 part of soluble cornstarch and 18 parts of water at room temperature to obtain the reaction base material, which is set aside;

[0048] S3. Uniformly mix 0.09 parts of vitamin C and 8 parts of water to obtain drop-in material A, and simultaneously add...

Embodiment 3

[0053] S1. To prepare a pre-emulsified monomer mixture, 4 parts of vinyl polyoxyethylene ether, 1.0 part of isopentenyl polyoxyethylene ether, 0.3 part of ethyl methacrylate, 0.8 part of n-butyl methacrylate, methacrylic acid 0.03 part of isobornyl ester, 0.01 part of isooctyl methacrylate, 0.06 part of octylphenol polyoxyethylene ether OP-4, 0.1 part of octylphenol polyoxyethylene ether OP-10, dodecyl diphenyl ether disulfonate 0.15 parts of sodium bicarbonate and 6 parts of water are stirred at a high speed under normal temperature conditions until the above reagents are emulsified into a uniform emulsion and set aside;

[0054] S2. Prepare the reaction base material by stirring and uniformly dissolving 25 parts of isopentenyl polyoxyethylene ether, 0.8 part of glucose, 0.03 part of soluble cornstarch and 8 parts of water at room temperature to obtain the reaction base material, which is set aside;

[0055] S3. Uniformly mix 0.08 parts of vitamin C and 8 parts of water to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com