3D printing porous surface zirconium oxide dental implant and design and processing method thereof

A 3D printing, porous surface technology, applied in the field of medical devices, can solve the problems of poor surface treatment effect and osseointegration performance, and achieve the effect of facilitating cell migration, promoting osseointegration, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

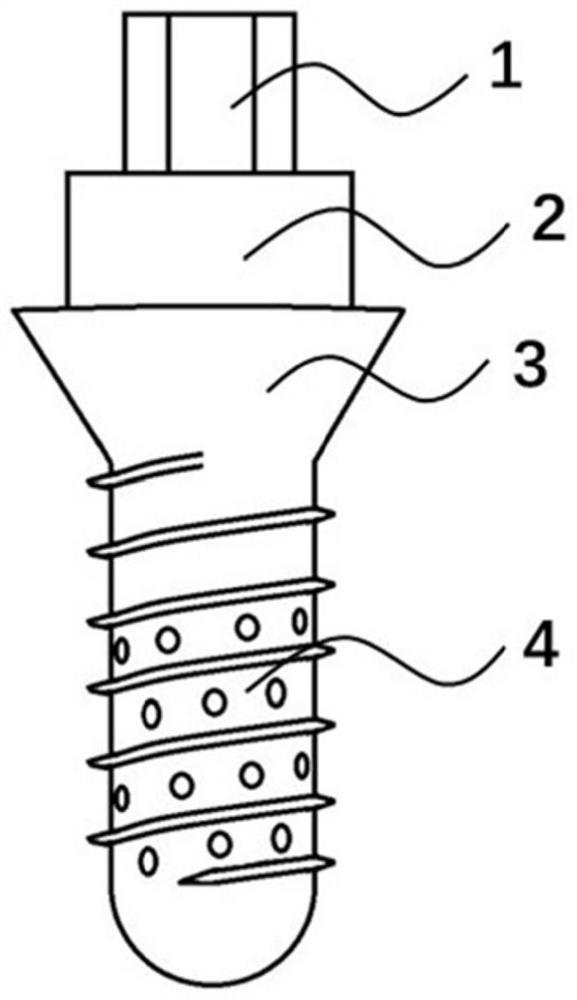

[0108] Porous surface design: the diameter of the implant is 4.5 mm, the porous structure is evenly distributed from 3 mm below the nominal bone plane to the end thread, the pore diameter is 100 μm, the hole depth is 150 μm, and 4 rows of porous bands can be arranged between adjacent threads. The perforated belts are arranged parallel to the rotation of the threads.

[0109] Material: The main components of the printing material are 3Y-TZP (polycrystalline tetragonal zirconia stabilized with 3% mol yttria) and photosensitive resin.

[0110] Printing parameters: printing angle 0°, printing layer thickness 25 μm, base support height of support structure 1.0 mm, gap with implant 0.2 mm, draft angle 10°.

[0111] Cleaning, drying, and degreasing and sintering: Remove the supporting structure from the printed implant, ultrasonically wash it in isopropanol solution for 10-15s, repeat 2-3 times, vacuum dry for 1min, and degrease and sinter for 52 hours.

[0112] Test data: static st...

Embodiment 2

[0115] Porous surface design: the diameter of the implant is 4.5 mm, the porous structure is evenly distributed from 3 mm below the nominal bone plane to the end thread, the pore diameter is 400 μm, the hole depth is 600 μm, and a row of porous bands can be arranged between adjacent threads. The perforated belts are arranged parallel to the direction of thread rotation.

[0116] Material: The main components of the printing material are 3Y-TZP (polycrystalline tetragonal zirconia stabilized with 3% mol yttria) and photosensitive resin.

[0117] Printing parameters: printing angle 0°, printing layer thickness 25 μm, base support height of support structure 1.0 mm, gap with implant 0.2 mm, draft angle 10°.

[0118] Cleaning, drying, and degreasing and sintering: Remove the supporting structure from the printed implant, ultrasonically wash it in isopropanol solution for 10-15s, repeat 2-3 times, vacuum dry for 1min, and degrease and sinter for 52 hours.

[0119] Test data: stati...

Embodiment 3

[0122] Porous surface design: the diameter of the implant is 4.5 mm, the porous structure is evenly distributed from 6 mm below the nominal bone plane to the end thread, the pore diameter is 400 μm, and the hole depth is 600 μm. A row of porous bands can be arranged between adjacent threads. The perforated belts are arranged parallel to the rotation of the threads.

[0123] Material: The main components of the printing material are 3Y-TZP (polycrystalline tetragonal zirconia stabilized with 3% mol yttria) and photosensitive resin.

[0124] Printing parameters: printing angle 0°, printing layer thickness 25 μm, base support height of support structure 1.0 mm, gap with implant 0.2 mm, draft angle 10°.

[0125] Cleaning, drying, and degreasing and sintering: Remove the supporting structure from the printed implant, ultrasonically wash it in isopropanol solution for 10-15s, repeat 2-3 times, vacuum dry for 1min, and degrease and sinter for 52 hours.

[0126] Test data: static str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com