Carbon nanotube catalyst prepared from Fenton reagent, method and application

A carbon nanotube and Fenton reagent technology, which is applied in the field of carbon nanotube catalyst preparation, can solve the problems of harsh conditions, surface structure damage, and complexity of carbon nanotube catalysts, and achieves easy large-scale application, small structural damage, and complete structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

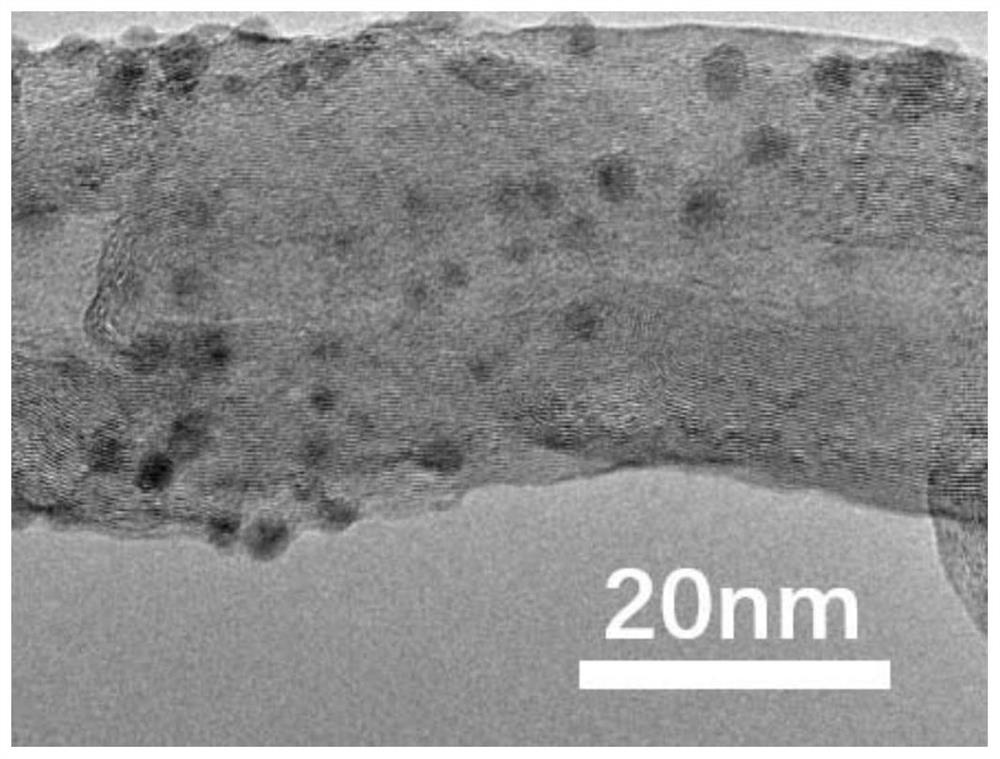

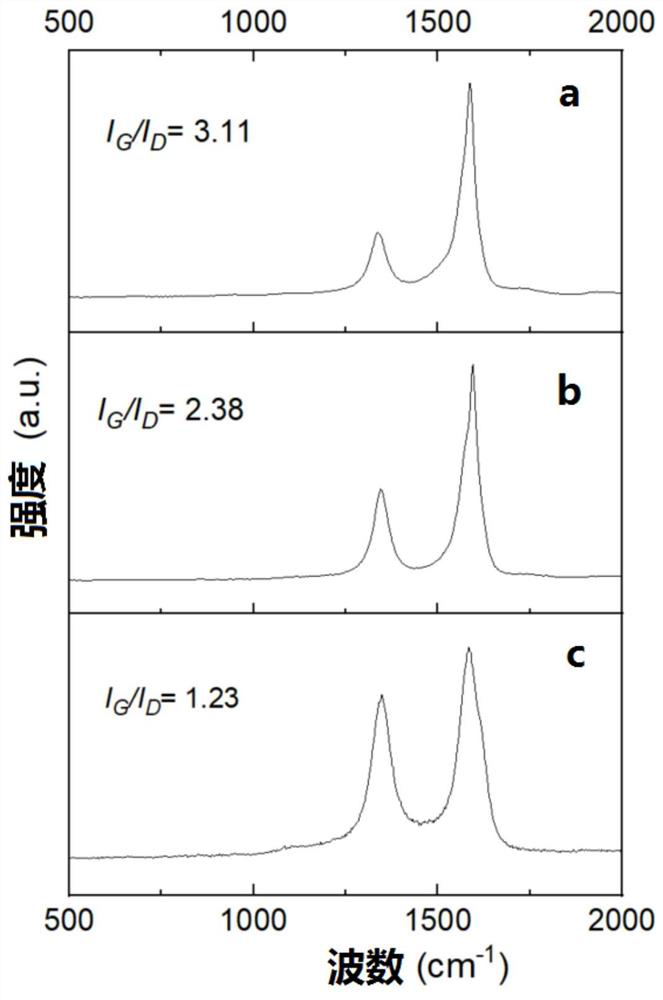

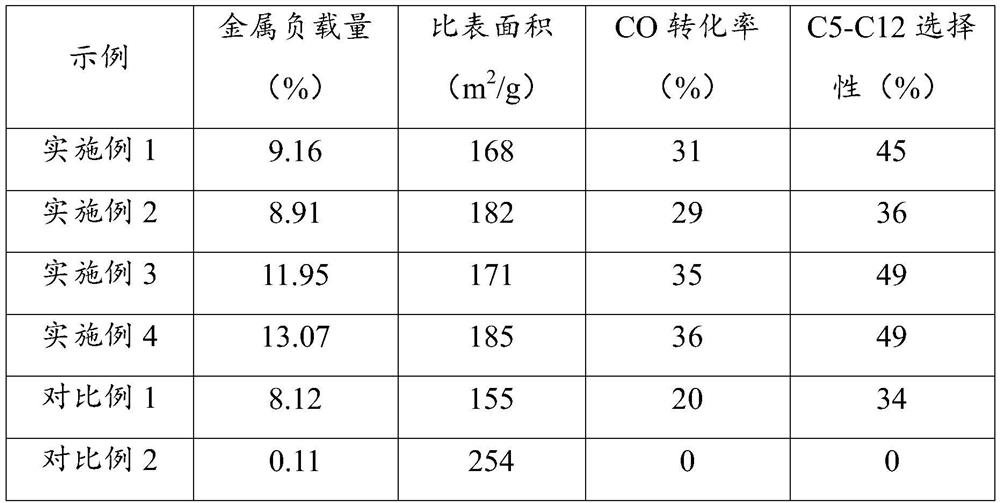

[0044]The present embodiment provides a kind of method utilizing Fenton's reagent to prepare carbon nanotube catalyst, comprises the following steps,

[0045] (1) Get a 250ml Erlenmeyer flask and place it on the magnetic heating stirring table, add 100g 30wt% H in the Erlenmeyer flask 2 o 2 Solution and 1g carbon nanotubes, turn on magnetic stirring; then add 0.8gCoCl 2 , to obtain the mixed solution, set aside;

[0046] (2) The mixed solution is placed under an ultraviolet lamp, the wavelength of the ultraviolet lamp is 365nm, the heating temperature is set to 40°C, and 10g of 30wt%H is added to the mixed solution every 6h 2 o 2 solution, to ensure that the H in the mixture 2 o 2 The mass of the catalyst does not exceed the initial mass, and the reaction time is 72 hours. After the reaction, turn off the ultraviolet lamp, filter it with a suction filter, add water to wash the catalyst filter cake three times, and dry it in an oven at 120 ° C for 12 hours to obtain a carb...

Embodiment 2

[0048] The present embodiment provides a kind of method utilizing Fenton's reagent to prepare carbon nanotube catalyst, comprises the following steps,

[0049] (1) Get a 250ml Erlenmeyer flask and place it on the magnetic heating stirring table, add 100g 30wt% H in the Erlenmeyer flask 2 o 2 Solution and 1g carbon nanotubes, turn on magnetic stirring; then add 0.8gFeCl 2 , to obtain the mixed solution, set aside;

[0050] (2) The mixed solution is placed under an ultraviolet lamp, the wavelength of the ultraviolet lamp is 365nm, the heating temperature is set to 40°C, and 10g of 30wt%H is added to the mixed solution every 6h 2 o 2 solution, to ensure that the H in the mixture 2 o 2 The mass of the catalyst does not exceed the initial mass, and the reaction time is 72 hours. After the reaction, turn off the ultraviolet lamp, filter it with a suction filter, add water to wash the catalyst filter cake three times, and dry it in an oven at 120 ° C for 12 hours to obtain a car...

Embodiment 3

[0052] The present embodiment provides a kind of method utilizing Fenton's reagent to prepare carbon nanotube catalyst, comprises the following steps,

[0053] (1) Get a 500ml Erlenmeyer flask and place it on the magnetic heating stirring table, add 200g 30wt% H in the Erlenmeyer flask 2 o 2 Solution and 1g carbon nanotubes, turn on magnetic stirring; then add 1.6gCoCl 2 , to obtain the mixed solution, set aside;

[0054] (2) The mixed solution is placed under an ultraviolet lamp, the wavelength of the ultraviolet lamp is 254nm, the heating temperature is set to 40°C, and 10g of 30wt%H is added to the mixed solution every 4h 2 o 2 solution, to ensure that the H in the mixture 2 o 2 The mass of the catalyst does not exceed the initial mass, and the reaction time is 48 hours. After the reaction, turn off the ultraviolet lamp, filter with a suction filter, add water to wash the catalyst filter cake three times, and dry it in an oven at 90 ° C for 15 hours to obtain a carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com