Organic-inorganic heavy metal ion trapping agent and preparation method thereof

A heavy metal ion and capture agent technology, applied in chemical instruments and methods, water treatment of special compounds, water/sewage treatment, etc., can solve the problems of difficult degradation of monomer toxicity, high price of synthetic polymer treatment agents, and application limitations. Achieve the effects of improving adsorption performance, reducing production costs, and strong coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

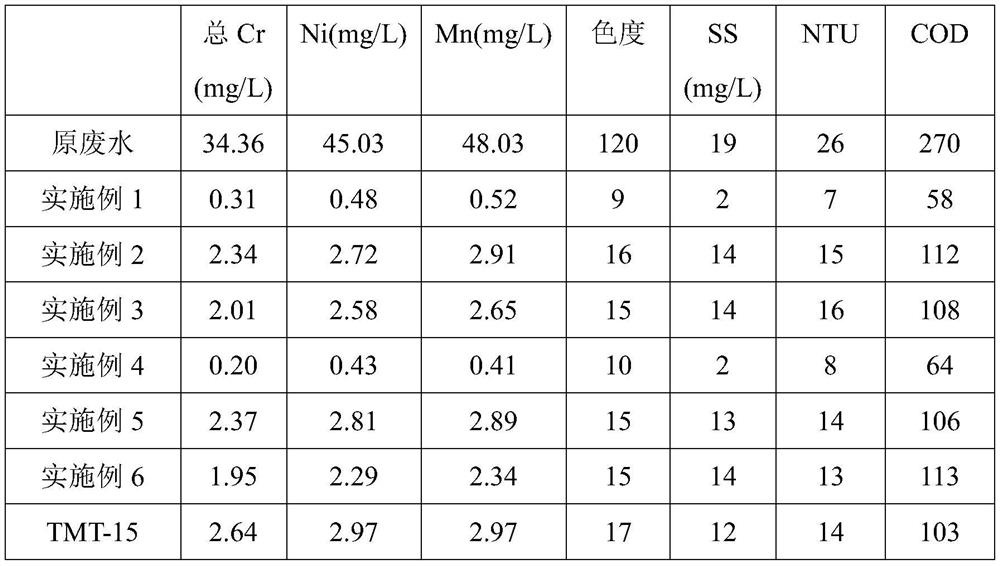

Examples

Embodiment 1

[0030] A kind of preparation of organic-inorganic heavy metal ion scavenger, concrete steps are as follows:

[0031] (1) Preparation of organic activated montmorillonite:

[0032] A. Dissolve 5g of montmorillonite in 500ml of distilled water, mix thoroughly and then stir for 4 hours to form a 1g / ml suspension, add citric acid to control the acid concentration at 3%, stir and mix for 3 hours, filter and wash until After neutralization, freeze-dry to obtain acid-modified montmorillonite;

[0033] In this step, after the montmorillonite is dissolved in distilled water, ultrasonic treatment may be performed for 1 hour after stirring to obtain a montmorillonite dispersion.

[0034] The freeze-drying conditions of the acid-modified montmorillonite are as follows: freezing at -25°C for 24 hours, then drying for 48 hours.

[0035] B. Reconfigure the acidified montmorillonite into a 2g / ml montmorillonite suspension, add the silane coupling agent vinyltriethoxysilane to the suspension...

Embodiment 2

[0041] A kind of preparation of organic-inorganic heavy metal ion scavenger, concrete steps are as follows:

[0042] (1) 2g humic acid is dissolved in the volume concentration 10% acetic acid solution, obtains the acid-modified humic acid solution of 0.1g / ml; 5g montmorillonite is added in the step (2) humic acid solution, stir Evenly dispersed;

[0043] (2) graft copolymerization reaction:

[0044] Add 0.4g initiator ammonium persulfate to the above solution, then add 20g acrylamide, react at 60°C for 6 hours, then use acetone as a precipitant to precipitate and separate the product, and obtain an organic-inorganic grafted metal scavenger.

Embodiment 3

[0046] A kind of preparation of organic-inorganic heavy metal ion scavenger, concrete steps are as follows:

[0047] (1) Preparation of organic activated montmorillonite:

[0048]A. Dissolve 5g of montmorillonite in 500ml of distilled water, mix thoroughly and then stir for 4 hours to form a 1g / ml suspension, add citric acid to control the acid concentration at 3%, stir and mix for 3 hours, filter and wash until After neutralization, freeze-dry to obtain acid-modified montmorillonite;

[0049] The freeze-drying conditions of the acid-modified montmorillonite are as follows: freezing at -25°C for 24 hours, then drying for 48 hours.

[0050] B. Reconfigure the acidified montmorillonite into a 2g / ml montmorillonite suspension, add the silane coupling agent vinyltriethoxysilane to the suspension, and carry out water under the condition of 40-65°C while stirring. Thermal reaction, solid-liquid separation after the reaction is completed, washing, drying, to obtain organic activate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com