Flame-retardant and sound-insulating coating and preparation method thereof

A sound insulation coating and particle size technology, applied in unspecified rubber coatings, coatings, etc., can solve the problems of poor thermal isolation effect, poor sound insulation effect, poor thermal insulation of reflective coatings, etc., to achieve good synergy, excellent reduction Shock buffering effect, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

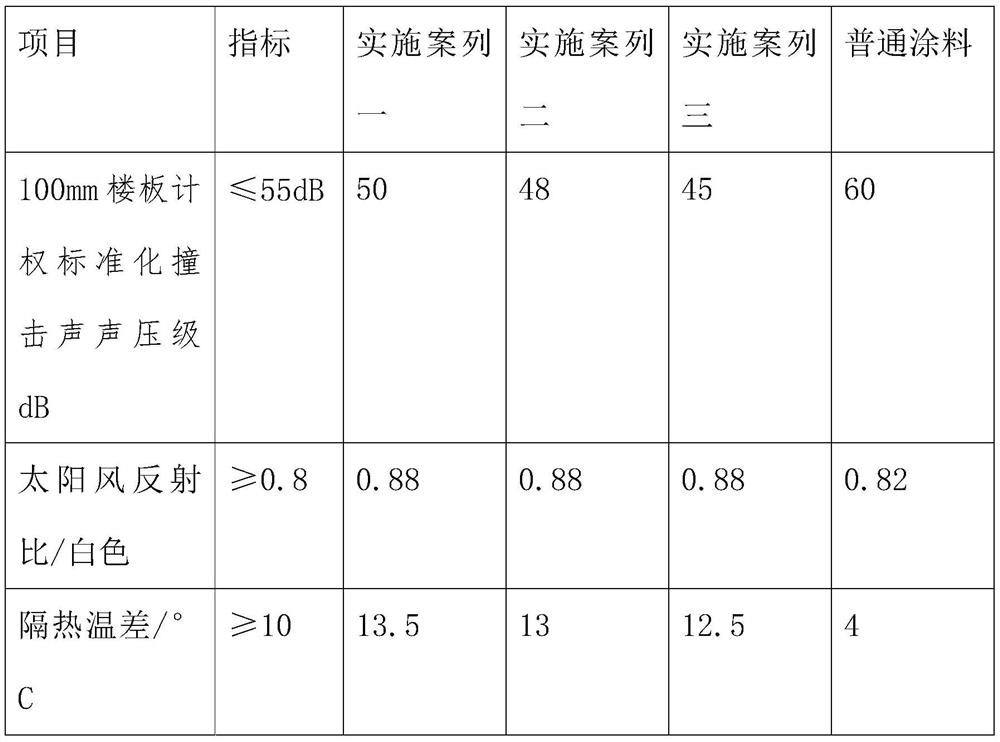

Examples

Embodiment 1

[0025] A flame-retardant soundproof coating, comprising (by mass percentage): 15% of silicon-acrylic emulsion, 15.56% of deionized water, 0.2% of cellulose, 0.47% of wood fiber, 0.3% of wetting and dispersing agent, 0.17% of antiseptic and bactericide, 1% flame retardant, 13% mica powder, 15% aluminum hydroxide, 10% vitrified bead mixture, 9% rubber powder, 0.3% PP fiber, 8% thermal insulation additive, and 12% shock-absorbing buffer.

[0026] Vitrified microbeads mixed particles include 20% of hollow vitrified microbeads with a particle size of 1-2mm, 30% of hollow vitrified microbeads with a particle size of 0.5-1mm, and 50% of hollow vitrified microbeads with a particle size of 0.2-0.3mm. The hollow vitrified microbeads with a diameter of 1-2mm, the hollow vitrified microbeads with a particle diameter of 0.5-1mm, and the hollow vitrified microbeads with a particle diameter of 0.2-0.3mm are uniformly mixed by a mixer to prepare vitrified microbead mixed particles.

[0027] P...

Embodiment 2

[0038] A flame-retardant soundproof coating, comprising (by mass percentage): 15% of silicon-acrylic emulsion, 15.56% of deionized water, 0.2% of cellulose, 0.47% of wood fiber, 0.3% of wetting and dispersing agent, 0.17% of antiseptic and bactericide, 1% flame retardant, 13% mica powder, 15% aluminum hydroxide, 10% vitrified bead mixture, 9% rubber powder, 0.3% PP fiber, 10% thermal insulation additive, and 10% shock-absorbing buffer.

[0039] Vitrified microbeads mixed particles include 20% of hollow vitrified microbeads with a particle size of 1-2mm, 30% of hollow vitrified microbeads with a particle size of 0.5-1mm, and 50% of hollow vitrified microbeads with a particle size of 0.2-0.3mm. The hollow vitrified microbeads with a diameter of 1-2mm, the hollow vitrified microbeads with a particle diameter of 0.5-1mm, and the hollow vitrified microbeads with a particle diameter of 0.2-0.3mm are uniformly mixed by a mixer to prepare vitrified microbead mixed particles.

[0040] ...

Embodiment 3

[0051] A flame-retardant soundproof coating, comprising (by mass percentage): 15% of silicon-acrylic emulsion, 15.56% of deionized water, 0.2% of cellulose, 0.47% of wood fiber, 0.3% of wetting and dispersing agent, 0.17% of antiseptic and bactericide, 1% flame retardant, 13% mica powder, 15% aluminum hydroxide, 10% vitrified bead mixed particles, 9% rubber powder, 0.3% PP fiber, 11% thermal insulation additive, and 9 shock-absorbing buffers.

[0052] Vitrified microbeads mixed particles include 20% of hollow vitrified microbeads with a particle size of 1-2mm, 30% of hollow vitrified microbeads with a particle size of 0.5-1mm, and 50% of hollow vitrified microbeads with a particle size of 0.2-0.3mm. The hollow vitrified microbeads with a diameter of 1-2mm, the hollow vitrified microbeads with a particle diameter of 0.5-1mm, and the hollow vitrified microbeads with a particle diameter of 0.2-0.3mm are uniformly mixed by a mixer to prepare vitrified microbead mixed particles.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com