Anti-oxidation production process of circuit board

A production process and anti-oxidation technology, applied in printed circuit, printed circuit manufacturing, printed circuit secondary treatment, etc., can solve the problems of anti-oxidation film high temperature resistance, poor compactness, etc., to improve the force and high temperature resistance and compactness, the effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

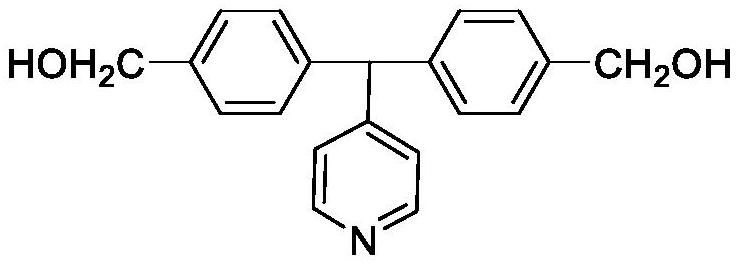

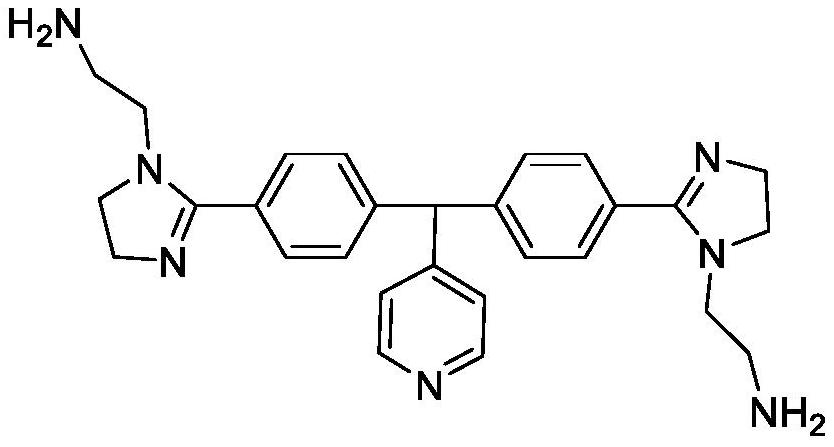

[0032] Preparation of imidazole derivatives:

[0033] Step 1: Add 0.01mol of pyridine-4-carbaldehyde, 0.025mol of benzyl alcohol and 10-20mL of glacial acetic acid into a three-necked flask in turn, stir evenly, cool to 0°C, and slowly add 25mL of concentrated sulfuric acid and glacial acetic acid dropwise while stirring The mixed solution, the dropping speed is 1 drop / second, continue to stir and react at 0°C for 48h after the dropwise addition is complete, then pour into ice water, stir for 50min, filter, take the filter cake and wash and filter repeatedly with ice water until the filtrate Neutral, then vacuum-dry the filter cake to constant weight to obtain benzyl alcohol derivatives, wherein the mixed solution of concentrated sulfuric acid and glacial acetic acid is a mixture of concentrated sulfuric acid and glacial acetic acid with a mass fraction of 98% in a volume ratio of 1:5 made;

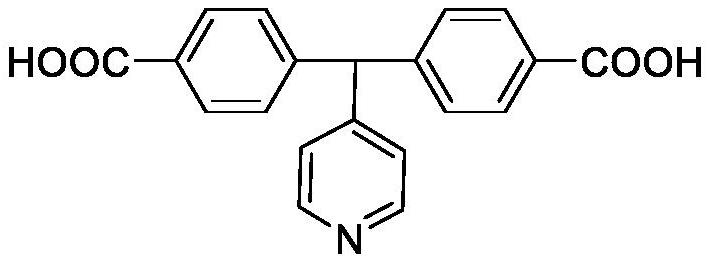

[0034] In the second step, after mixing 0.1mol of benzyl alcohol derivatives and eth...

Embodiment 2

[0038] Preparation of imidazole derivatives:

[0039] Step 1: Add 0.01mol of pyridine-4-carbaldehyde, 0.03mol of benzyl alcohol and 20mL of glacial acetic acid into a three-necked flask in turn, stir evenly, cool to 0°C, and slowly add 35mL of concentrated sulfuric acid and glacial acetic acid dropwise while stirring Solution, the dropping rate is 1 drop / second, after the drop is complete, continue to stir and react at 0°C for 48h, then pour into ice water, stir for 50min, filter, take the filter cake and wash and filter repeatedly with ice water until the filtrate is medium Then vacuum-dry the filter cake to constant weight to obtain benzyl alcohol derivatives, wherein the mixed solution of concentrated sulfuric acid and glacial acetic acid is formed by mixing concentrated sulfuric acid and glacial acetic acid with a mass fraction of 98% in a volume ratio of 1:5 ;

[0040] The second step, after mixing 0.1mol benzyl alcohol derivatives and ether, stir slightly until the benz...

Embodiment 3

[0044] A production process for circuit board anti-oxidation, comprising the following steps:

[0045] Step 1. Alkaline cleaning: Soak the PCB board with 5% sodium hydroxide solution at 20°C for 10 minutes, then rinse it with water for 10 minutes to remove the grease on the surface of the PCB board, and obtain the PCB board with alkali cleaning;

[0046] Step 2. Acid neutralization: wash the alkaline-washed PCB board with 5% dilute sulfuric acid at 20°C for 24 minutes, and then rinse it with water for 8 minutes to obtain an acid-neutralized PCB board;

[0047] Step 3, microetching: immerse the acid-neutralized PCB board in a microetching solution at 20°C for 4 minutes, then rinse with water for 4 minutes, and dry to obtain a microetching PCB board. The microetching solution includes 5% sulfuric acid and mass fraction 5% hydrogen peroxide is mixed according to the volume ratio of 2:1;

[0048] Step 4. Weigh the following raw materials by weight: 2 g of imidazole derivatives pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com