A kind of high-entropy alloy micro-wire for anti-oxidation additive manufacturing and its synthesis method

A high-entropy alloy and additive manufacturing technology, applied in the direction of manufacturing tools, additive processing, furnaces, etc., can solve the problems of plasticity decline, difficulty in overcoming high strength and high life, and inability to coordinate and unify, so as to achieve stable organization and powerful processing Hardening ability, effect of uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

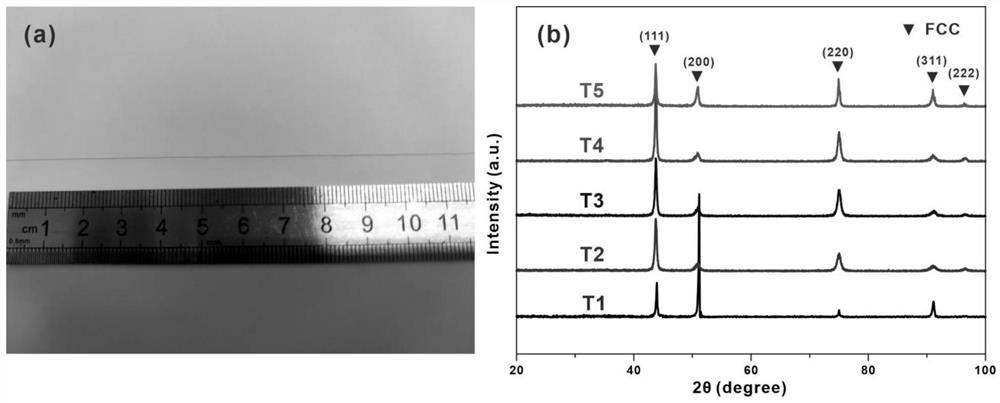

[0028] A high-entropy alloy micro-wire for anti-oxidation additive manufacturing, the alloy composition of the high-entropy alloy micro-wire is Al 0.5 CoCr 0.8 FeNi 2.5 V 0.2 , that is, the atomic ratio of Al, Co, Cr, Fe, Ni, and V is 0.5:1:0.8:1:2.5:0.2. The high-entropy alloy is smelted from bulk Al, Co, Cr, Fe, Ni, and V with a purity of ≥99.99%.

[0029] The above-mentioned synthesis method of high-entropy alloy micro-wire for anti-oxidation additive manufacturing comprises the following steps:

[0030] S1. Ingredients

[0031] The surface of each metal element raw material is treated to remove the oxide skin layer, and each raw material is ultrasonically cleaned with acetone cleaning solution, and then according to the atomic ratio of each element metal element Al, Co, Cr, Fe, Ni, V 0.5:1:0.8 :1:2.5:0.2, calculate the mass of each metal element with a total mass of 30g and weigh;

[0032] S2. Preparation of alloy ingots

[0033] Using the arc smelting method, each ...

Embodiment 2

[0039] A high-entropy alloy micro-wire for anti-oxidation additive manufacturing, the alloy composition of the high-entropy alloy micro-wire is Al 0.5 CoCr 0.8 FeNi 2.5 V 0.2 , that is, the atomic ratio of Al, Co, Cr, Fe, Ni, and V is 0.5:1:0.8:1:2.5:0.2. The high-entropy alloy is smelted from bulk Al, Co, Cr, Fe, Ni, and V with a purity of ≥99.99%.

[0040] The above-mentioned synthesis method of high-entropy alloy micro-wire for anti-oxidation additive manufacturing comprises the following steps:

[0041] S1. Ingredients

[0042] The surface of each metal element raw material is treated to remove the oxide skin layer, and each raw material is ultrasonically cleaned with acetone cleaning solution, and then according to the atomic ratio of each element metal element Al, Co, Cr, Fe, Ni, V 0.5:1:0.8 :1:2.5:0.2, calculate the mass of each metal element with a total mass of 30g and weigh;

[0043] S2. Preparation of alloy ingots

[0044] Using the arc melting method, each m...

Embodiment 3

[0052] A high-entropy alloy micro-wire for anti-oxidation additive manufacturing, the alloy composition of the high-entropy alloy micro-wire is Al 0.5 CoCr 0.8 FeNi 2.5 V 0.2 , that is, the atomic ratio of Al, Co, Cr, Fe, Ni, and V is 0.5:1:0.8:1:2.5:0.2. The high-entropy alloy is smelted from bulk Al, Co, Cr, Fe, Ni, and V with a purity of ≥99.99%.

[0053] The above-mentioned synthesis method of high-entropy alloy micro-wire for anti-oxidation additive manufacturing comprises the following steps:

[0054] S1. Ingredients

[0055] The surface of each metal element raw material is treated to remove the oxide skin layer, and each raw material is ultrasonically cleaned with anhydrous ethanol cleaning solution, and then according to the atomic ratio of each element metal element Al, Co, Cr, Fe, Ni, V 0.5:1 :0.8:1:2.5:0.2, calculate the mass of each metal element with a total mass of 30g and weigh;

[0056] S2. Preparation of alloy ingots

[0057] Using the arc melting meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com