Ethylene glycol terephthalate/graphene two-dimensional layered composite film with T-shaped channel structure as well as preparation method and application of ethylene glycol terephthalate/graphene two-dimensional layered composite film

A ethylene terephthalate, two-dimensional layered technology, applied in the field of membrane materials, can solve the problems of low selectivity and poor flexibility of organic submicron porous membranes, and achieves overcoming poor flexibility and easy operation. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

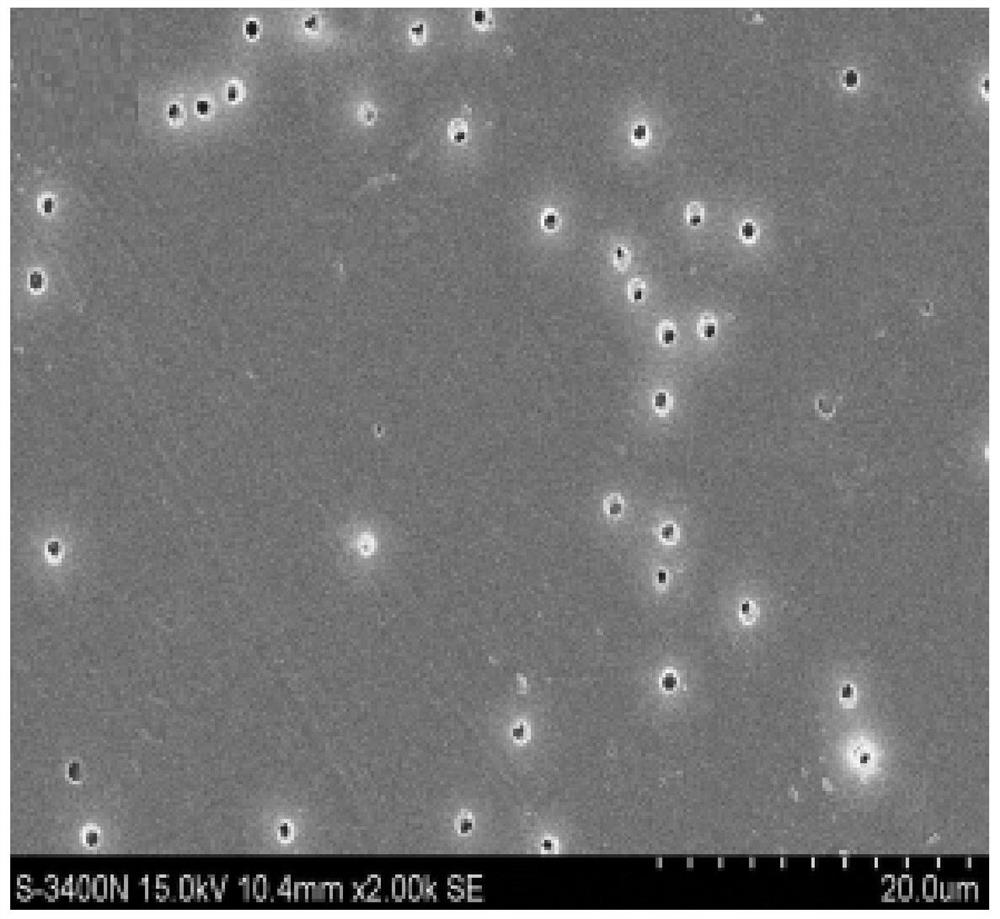

[0048] Preparation of an ethylene terephthalate / graphene-based two-dimensional layered composite film with a T-shaped channel structure.

[0049] 2.0-4.0 ml of commercialized 2 g / L single-layer graphene nanosheet n-methyl-2-pyrrolidone (NMP) dispersion (Beijing Beike New Material Technology Co., Ltd., single-layer graphene nanosheet size: 0.5 micron-3.0 micron) into a 20 ml centrifuge tube and place it in a high-speed centrifuge, centrifuge at a speed of 5000 rpm for 50 minutes, remove the supernatant containing small-diameter graphene in the centrifuge tube, and then add it to the centrifuge tube After 20 milliliters of isopropanol, ultrasonically disperse for 3 minutes to obtain a graphene nanosheet precursor solution (0.2 g / L) for preparing ethylene terephthalate / graphene two-dimensional layered composite film.

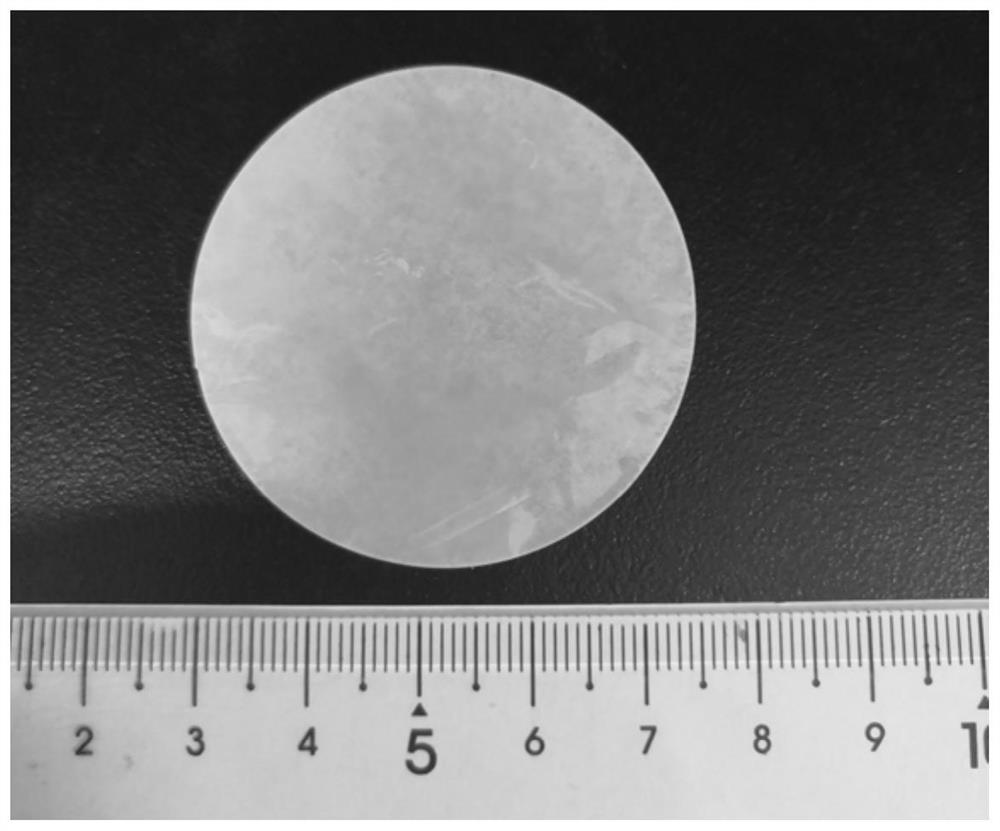

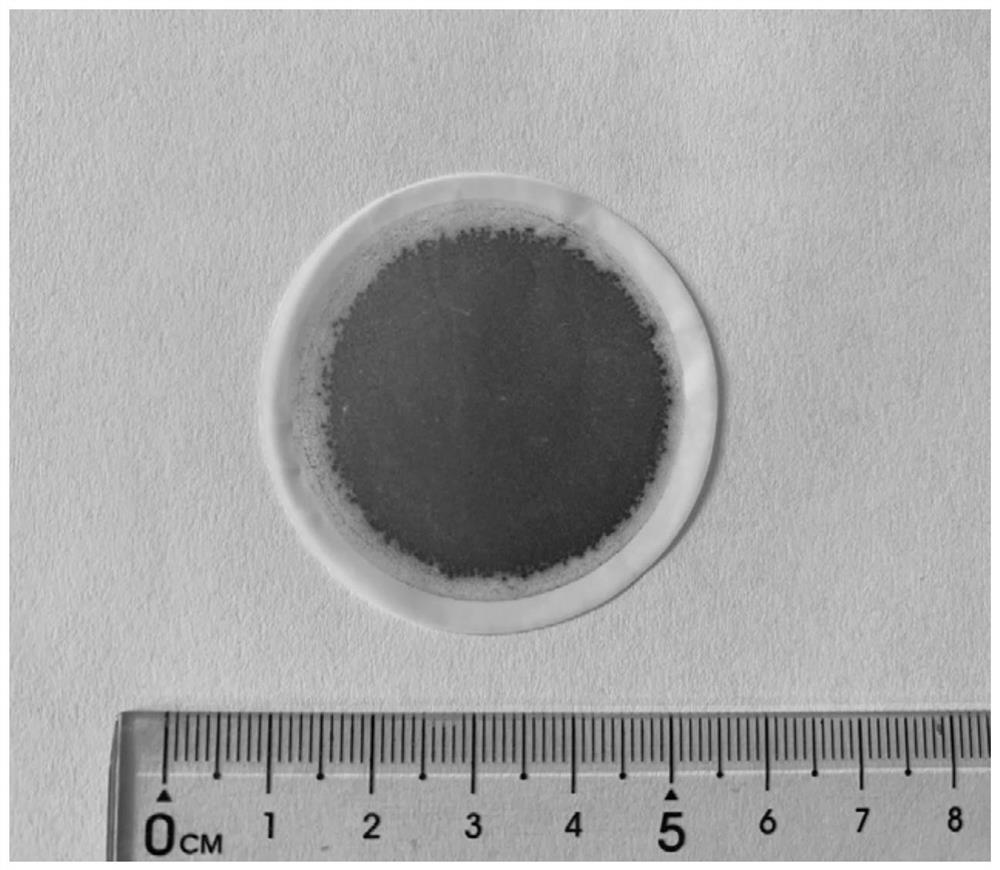

[0050] Take 1.0 ml of 0.2 g / L graphene nanosheet precursor solution, add it dropwise on the porous ethylene terephthalate membrane in the vacuum filtration device,...

Embodiment 2

[0053] A kind of aqueous solution ion sieving of the ethylene terephthalate / graphene-based two-dimensional layered film with T-type channel structure, specifically comprises the steps:

[0054] Weigh a certain amount of potassium chloride (KCl), sodium chloride (NaCl), lithium chloride (LiCl), magnesium chloride (MgCl) 2 ), tetraethylammonium chloride (TEACl) and tetrabutylammonium chloride (TBACl) are added to the volumetric flask, and the volume is adjusted to 50 ml with deionized water, and it is configured into a 0.1 mol / liter aqueous solution, which will have a T-shaped channel The structural ethylene terephthalate / graphene two-dimensional layered composite membrane is placed in a U-shaped ion transport cell, and the same concentration and volume of potassium chloride, sodium chloride, and chloride are added to both sides of the transport cell. Lithium, magnesium chloride, tetraethylammonium chloride and tetrabutylammonium chloride, using a four-electrode system to test t...

Embodiment 3

[0057] A kind of ion transmission and screening on the oil / water interface of the ethylene terephthalate / graphene-based two-dimensional layered film with T-shaped channel structure, specifically comprising the steps of:

[0058] Mix 0.1 mol / liter of potassium chloride, sodium chloride, lithium chloride, magnesium chloride aqueous solution (W) with 0.02 mol / liter of tetrabutylammonium tetraphenylborate 1,2-dichloroethane organic solution (DCE ) in a four-electrode system electrochemical cell to form a polarizable W / DCE interface supported by ethylene terephthalate / graphene two-dimensional layered composite film, using CHI760D electrochemical workstation and cyclic voltammetry (CV) and differential Pulse voltammetry (DPV) and electrochemical measurements of ion transfer on the polarizable W / DCE interface were performed using a four-electrode system. The four-electrode system means that the counter electrode (CE) in the water phase and the oil phase is a platinum wire electrode, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com