Finish paint for building aluminum veneer curtain wall and preparation method thereof

A technology for aluminum veneer and curtain wall, applied in the direction of coating, anti-corrosion coating, etc., can solve the problems that need to be improved, and achieve the effects of reducing micropores, good heat insulation, and improving film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

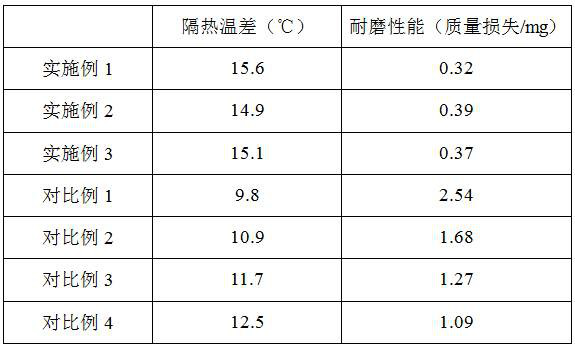

Examples

Embodiment 1

[0037] A building aluminum veneer curtain wall finish paint, comprising A component and B component, the weight ratio of the A component and B component is 9:1.

[0038] The A component is prepared from the following raw materials in parts by weight: 45 parts of polyvinylidene fluoride resin, 18 parts of filler, 6 parts of modified carbon nanotubes, 5 parts of methyl methacrylate resin, 2 parts of silica sol, 2 parts Parts of dispersant, 1.8 parts of 3-(trihydroxysilyl) propyl methyl phosphate, 1.5 parts of 4-aminophenylboronic acid, 1.2 parts of diethylenetriamine, 1 part of ethylene glycol butyl ether, 0.8 parts of defoamer, 0.5 parts Part hydroxyethyl cellulose, 0.4 part dioctyl phthalate, 0.1 part triethanolamine, 14.7 parts solvent.

[0039] The solvent is composed of butyl acetate and propylene glycol methyl ether acetate in a weight ratio of 1:0.5.

[0040] The defoamer is BYK-141.

[0041] The dispersant is BYK-110.

[0042] The polyvinylidene fluoride resin is purc...

Embodiment 2

[0057] A building aluminum veneer curtain wall finish paint, comprising A component and B component, the weight ratio of the A component and B component is 8:1.

[0058] The A component is prepared from the following raw materials in parts by weight: 45.25 parts of polyvinylidene fluoride resin, 12 parts of filler, 7 parts of modified carbon nanotubes, 4 parts of methyl methacrylate resin, 3 parts of silica sol, 1.5 parts Parts of dispersant, 2 parts of 3-(trihydroxysilyl) propyl methyl phosphate, 1 part of 4-aminophenylboronic acid, 1.8 parts of diethylenetriamine, 0.6 parts of ethylene glycol butyl ether, 0.9 parts of defoamer, 0.3 parts Part hydroxyethyl cellulose, 0.6 part dioctyl phthalate, 0.05 part triethanolamine, 20 parts solvent.

[0059] The solvent is composed of butyl acetate and propylene glycol methyl ether acetate in a weight ratio of 1:0.5.

[0060] The defoamer is BYK-141.

[0061] The dispersant is BYK-110.

[0062] The polyvinylidene fluoride resin is pu...

Embodiment 3

[0076] A building aluminum veneer curtain wall finish paint, comprising A component and B component, the weight ratio of the A component and B component is 9:1.

[0077] The A component is prepared from the following raw materials in parts by weight: 47.05 parts of polyvinylidene fluoride resin, 17 parts of filler, 3 parts of modified carbon nanotubes, 8 parts of methyl methacrylate resin, 1 part of silica sol, 2.5 parts Parts of dispersant, 1.2 parts of 3-(trihydroxysilyl) propyl methyl phosphate, 1.6 parts of 4-aminophenylboronic acid, 1 part of diethylenetriamine, 1.2 parts of ethylene glycol butyl ether, 0.5 parts of defoamer, 0.6 parts Parts of hydroxyethyl cellulose, 0.2 parts of dioctyl phthalate, 0.15 parts of triethanolamine, and 15 parts of solvent.

[0078] The B component consists of 88 parts by weight of hexamethylene diisocyanate resin and 12 parts by weight of sodium hexametaphosphate.

[0079] The solvent is composed of butyl acetate and propylene glycol methy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com