Polyester transparent powder coating and preparation method thereof

A powder coating and transparent technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of low raw material cost and production cost, poor surface aesthetics and durability, unsatisfactory transparency and leveling performance, etc. Achieve high adhesion strength, excellent bending performance, and improve transparency and adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

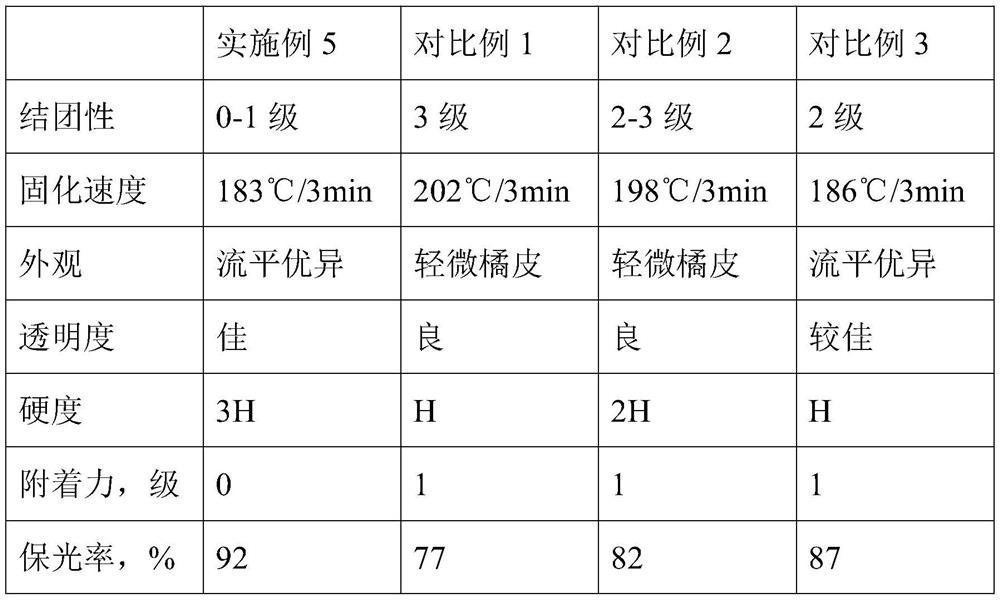

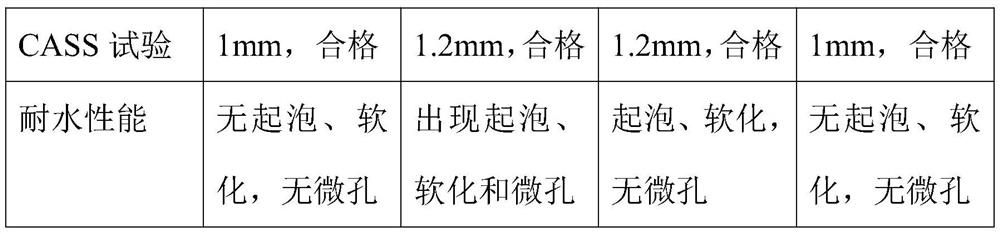

Examples

Embodiment 1

[0026] Polyester transparent powder coating, its raw materials include: polyester resin 40kg, diethanolamine 3kg, methyl acrylate 3kg, trimethylolpropane 5kg, catalyst 2kg, stearic acid 1kg, barium sulfate 5kg, calcium carbonate 5kg, silicon dioxide 5kg, graphene 3kg, curing agent 1kg, dispersant 2kg, leveling agent 1kg, light stabilizer 2kg, defoamer 1kg.

[0027] The preparation method of above-mentioned polyester transparent powder coating, comprises the steps:

[0028] S1. Mix barium sulfate, calcium carbonate, silicon dioxide, and graphene, and stir at 150°C for 5 minutes to obtain a premixed filler;

[0029] S2. Add polyester resin, premixed filler, curing agent, dispersant, leveling agent, light stabilizer, and defoamer into a high-speed mixer, and stir at 75°C for 1 hour to obtain premix a;

[0030] S3. Add diethanolamine to 40kg methanol and stir evenly, add methyl acrylate, stir at 40°C for 4h, filter under reduced pressure, add to trimethylolpropane, stir at 50°C f...

Embodiment 2

[0033] Polyester transparent powder coating, its raw materials include: polyester resin 100kg, diethanolamine 1kg, methyl acrylate 8kg, trimethylolpropane 1kg, catalyst 6kg, stearic acid 0.1kg, barium sulfate 10kg, calcium carbonate 1kg, dioxide Silicon 15kg, graphene 1kg, curing agent 5kg, dispersant 1kg, leveling agent 2kg, light stabilizer 1kg, defoamer 5kg.

[0034] The preparation method of above-mentioned polyester transparent powder coating, comprises the steps:

[0035] S1. Mix barium sulfate, calcium carbonate, silicon dioxide, and graphene, and stir at 100°C for 15 minutes to obtain a premixed filler;

[0036] S2. Add polyester resin, premixed filler, curing agent, dispersant, leveling agent, light stabilizer, and defoamer to a high-speed mixer, stir at 65°C for 2 hours, and obtain premix a;

[0037] S3. Add diethanolamine to 20kg methanol and stir evenly, add methyl acrylate, stir at 50°C for 2h, filter under reduced pressure, add to trimethylolpropane, stir at 60°...

Embodiment 3

[0040] Polyester transparent powder coating, its raw materials include: polyester resin 60kg, diethanolamine 2.5kg, methyl acrylate 4kg, trimethylolpropane 4kg, catalyst 3kg, stearic acid 0.7kg, barium sulfate 6kg, calcium carbonate 4kg, di Silicon oxide 8kg, graphene 2.5kg, curing agent 2kg, dispersant 1.7kg, leveling agent 1.2kg, light stabilizer 1.8kg, defoamer 2kg.

[0041] The preparation method of above-mentioned polyester transparent powder coating, comprises the steps:

[0042] S1. Mix barium sulfate, calcium carbonate, silicon dioxide, and graphene, and stir at 140°C for 8 minutes to obtain a premixed filler;

[0043] S2. Add polyester resin, premixed filler, curing agent, dispersant, leveling agent, light stabilizer, and defoamer to a high-speed mixer, and stir at 72°C for 1.3 hours to obtain premix a;

[0044] S3. Add diethanolamine to 35kg methanol and stir evenly, add methyl acrylate, stir at 42°C for 3.5h, filter under reduced pressure, add to trimethylolpropane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com