High-protein yoghourt and preparation process thereof

A preparation process and high-protein technology, applied in the field of high-protein yogurt and its preparation process, can solve the problems of few types of protein powder, complex process flow, high requirements for protein powder, etc., optimize structure and function, solve serious powdery taste, Flavor and taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

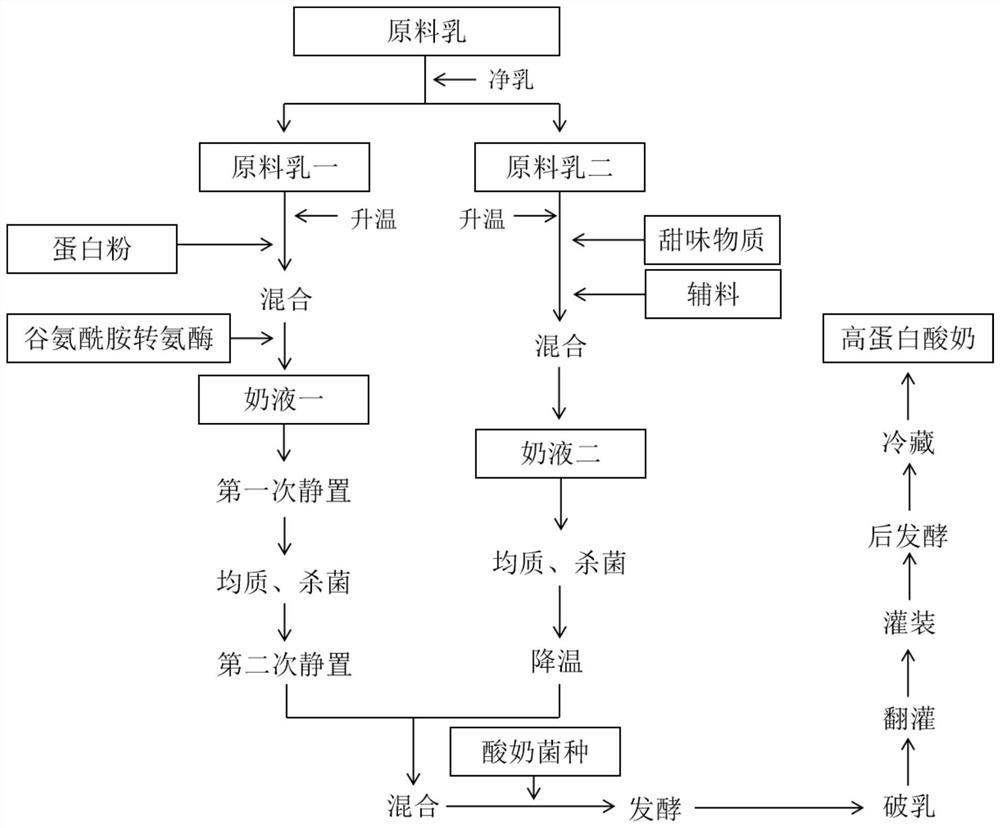

Method used

Image

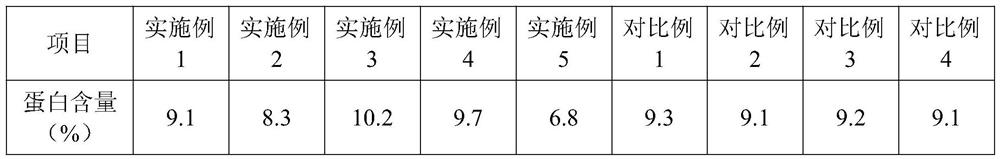

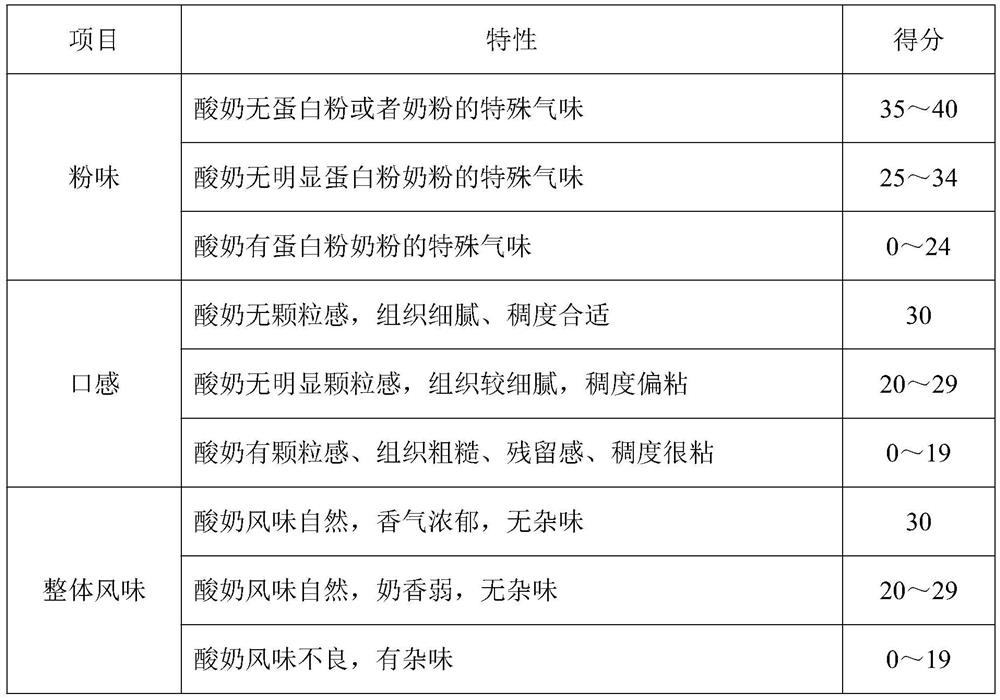

Examples

Embodiment 1

[0046] Take raw materials according to the following proportions: 86.9 parts of raw milk, 5 parts of white sugar, 4 parts of whey protein powder, 4 parts of milk protein powder, 0.04 parts of transglutaminase, 0.03 parts of Lactobacillus bulgaricus and 0.03 parts of Streptococcus thermophilus share. The preparation steps are as follows:

[0047] Take raw milk and clean milk at a rotating speed of 5000r / min, and use 50.9 parts of raw milk after cleaning as raw milk 1, and 36 parts of raw milk as raw milk 2;

[0048] Raise the temperature of raw milk 1 to 50°C, add whey protein powder and milk protein powder, stir and mix evenly, add glutamine transaminase to obtain milk liquid 1, let milk liquid 1 stand at 50°C for 40 minutes, and then put Once the milk is heated to 60°C, it is homogenized under a pressure of 250 bar. After the end, the temperature is raised to 95°C in the sterilizer and kept for 300s for pasteurization; once the sterilized milk is cooled to 4°C, it is left to...

Embodiment 2

[0051] The raw materials are taken according to the following proportions: 90.95 parts of raw milk, 4 parts of sucralose, 5 parts of milk protein powder, 0.03 parts of transglutaminase, and 0.04 parts of Streptococcus thermophilus. The preparation steps are as follows:

[0052] Take the raw milk and clean it at a rotating speed of 6000r / min, and use 50.93 parts of the cleaned raw milk as raw material milk 1, and 40 parts of raw milk as raw material milk 2;

[0053] Raise the temperature of the raw milk to 50°C, add milk protein powder, stir and mix evenly, add glutamine transaminase to obtain the milk liquid, let the milk liquid stand at 50°C for 30 minutes, and then heat the milk liquid to Homogenize at 60°C under a pressure of 250bar. After the end, heat up to 95°C in a sterilizer and keep for 300s for pasteurization; cool the sterilized milk to 2°C and let it stand for 15 hours; heat up the raw milk To 50°C, add sucralose, stir and mix evenly to obtain milk liquid 2, heat ...

Embodiment 3

[0056] Take raw materials according to the following proportions: 84.9 parts of raw milk, 5 parts of glucose, 2 parts of whey protein powder, 5 parts of milk protein powder, 3 parts of desalted whey powder, 0.04 parts of transglutaminase, and 0.06 parts of Lactobacillus bulgaricus .

[0057] Take the raw milk and clean it at a speed of 6000r / min, use 44.9 parts of the cleaned raw milk as raw material 1, and 40 parts of raw milk as raw material 2.

[0058] Heat raw milk 1 to 50°C, add whey protein powder, milk protein powder, and desalted whey powder, stir and mix evenly, add glutamine transaminase to obtain milk liquid 1, and leave milk liquid 1 at 55°C for 60 minutes , after standing still, heat the milk to 60°C, homogenize under 200bar pressure, after the end, heat up to 95°C in the sterilizer, keep it for 300s for pasteurization; cool the sterilized milk to 4°C , stand still for 20 hours; raise the temperature of raw milk II to 50°C, add glucose, stir and mix evenly to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com