Weak-dispersion early-strength retarder for oil well cement and preparation method thereof

An early-strength technology for oil well cement, which is applied in the field of oilfield chemicals and admixtures for oil well cement cementing. Stability deterioration and other issues, to achieve the effect of good compatibility and compatibility, low cost, and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

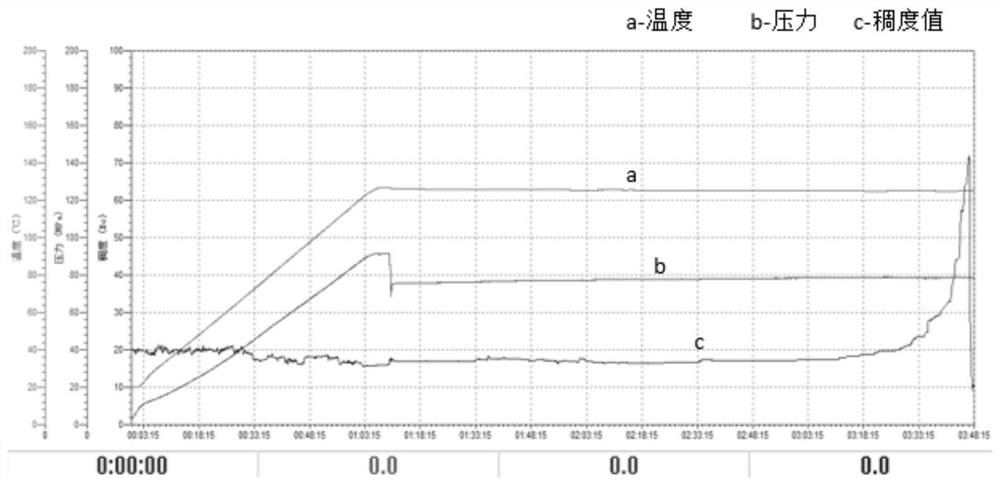

Embodiment 1

[0039]This embodiment provides a weakly dispersed early-strength type oil well cement retarder and its preparation method, comprising the following steps, by weight, 20 parts of AMPS, 20 parts of unsaturated carboxylic acid monomer, 10 parts of acrylamide 1. Add water to 15 parts of non-ionic macromonomer, stir until completely dissolved, add 0.1 part of sodium hydroxide solution with a mass concentration of 30% to adjust the pH to 4, stir evenly, heat up to 65°C, and then dropwise add 0.2 parts of Concentration is 10% redox system initiator, 0.1 part of mass concentration is 10% azo initiator system to carry out reaction synthesis, after stirring for 3 hours, make copolymer solution, obtain retarder solution;

[0040] Among them, the unsaturated carboxylic acid monomer is itaconic acid; the non-ionic macromonomer is isoprenyl polyethylene glycol ether; the redox initiator is potassium persulfate; the azo initiator is azodiiso Butamidine hydrochloride.

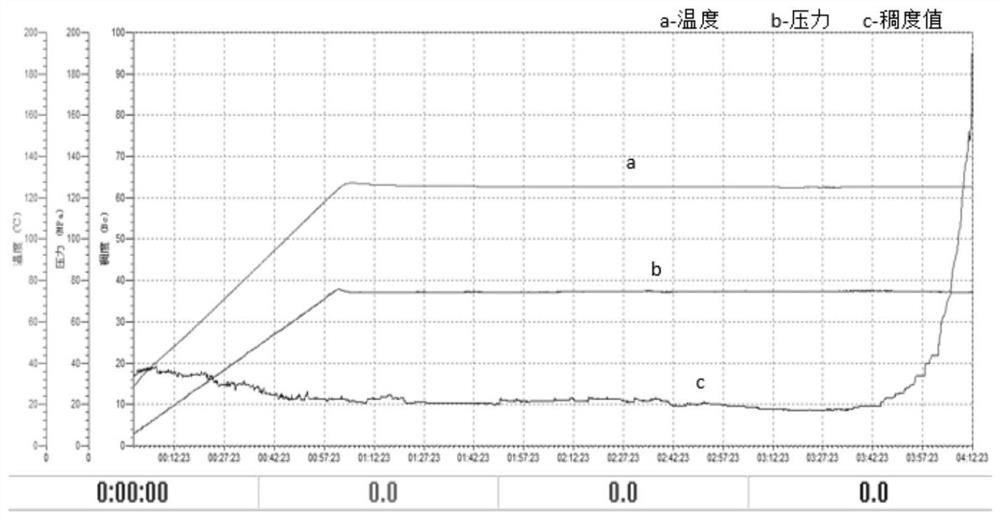

Embodiment 2

[0042] This embodiment provides a kind of retarder for weakly dispersed early-strength oil well cement and its preparation method, comprising the following steps, by weight, 30 parts of AMPS, 15 parts of unsaturated carboxylic acid monomer, 8 parts of acrylamide 1. Add water to 5 parts of non-ionic macromonomer, stir until completely dissolved, add 0.1 part of sodium hydroxide solution with a mass concentration of 30% to adjust the pH to 5, stir evenly and heat up to 75°C, and then dropwise add 0.2 parts of Concentration is 10% redox system initiator, 0.1 part of mass concentration is 10% azo initiator system to carry out reaction synthesis, after stirring for 3 hours, make copolymer solution, obtain retarder solution;

[0043] Among them, the unsaturated carboxylic acid monomer is acrylic acid; the nonionic macromer is α-methallyl-ω-methoxy; the redox initiator is ammonium persulfate and sodium bisulfite; The agent is azodiisopropylimidazoline hydrochloride.

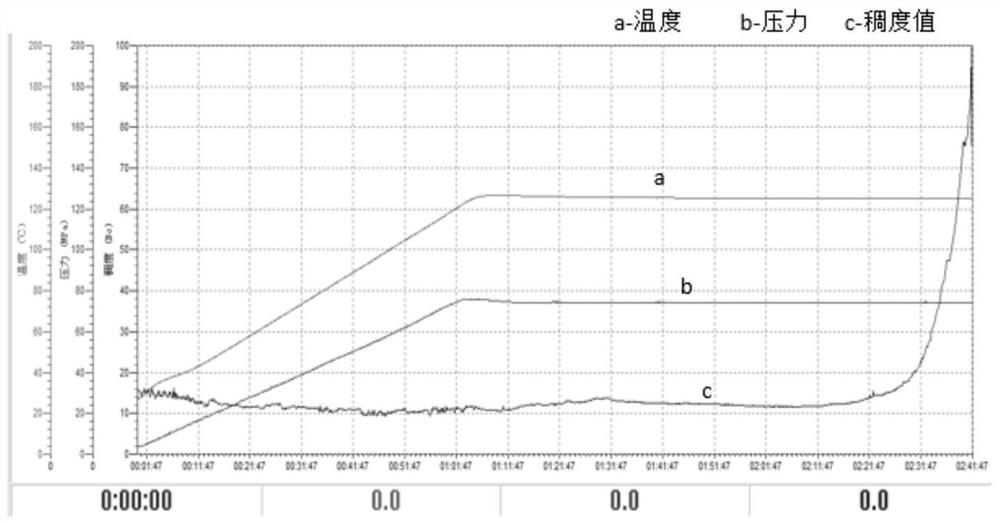

Embodiment 3

[0045] This embodiment provides a weakly dispersed early-strength type oil well cement retarder and its preparation method, comprising the following steps, by weight, 15 parts of AMPS, 25 parts of unsaturated carboxylic acid monomer, 10 parts of acrylamide 1. Add water to 15 parts of non-ionic macromonomer, stir until completely dissolved, then add 0.1 part of sodium hydroxide solution with a mass concentration of 30% to adjust the pH to 4.5, stir evenly and heat up to 80°C, then add 0.3 parts of Concentration is 10% redox system initiator, 0.2 parts of mass concentration is 10% azo initiator system for reaction synthesis, after stirring for 3 hours, a copolymer solution is prepared, which is a retarder solution;

[0046] Among them, the unsaturated carboxylic acid monomer is fumaric acid; the non-ionic macromonomer is ω-hydroxy polyethylene glycol; the redox initiator is potassium persulfate; the azo initiator is azodiisopropylimidazole Phenyl hydrochloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com